Method for preparing high anti-bacterial alginate dressing

An alginate and antibacterial technology, which is applied in the field of preparation of high antibacterial alginate dressings, can solve the problems of easy shedding of nano-ions, insufficient bonding, and decreased antibacterial performance of alginate dressings, and achieve good antibacterial performance , long-lasting antibacterial effect, and the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

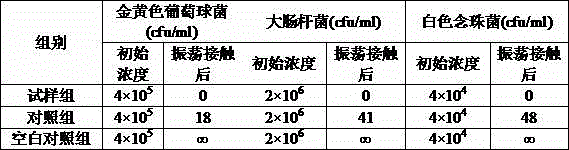

Examples

Embodiment 1

[0024] A preparation method of high antibacterial alginate dressing, the specific steps are as follows:

[0025] (1) Surface activation of alginate fibers: Cut 3.00 g of alginate fibers into short fibers with a length of 3-5 cm, soak them in ethanol for 2 hours, and ultrasonically treat them at 60°C for 20 minutes. Wash with deionized water several times, filter by suction and dry at room temperature;

[0026] (2) Functional modification of alginate fibers: add the surface-activated alginate fibers in step (1) to 100 ml of dimethyl diallyl ammonium chloride, raise the temperature to 50°C, and add 2 ml An aqueous solution of 0.04 g of ferrous ammonium sulfate and 0.8 ml of 30% hydrogen peroxide were added and reacted, and the reaction was stirred for 3 h. After washing with deionized water several times, it was vacuum dried at 50°C to obtain 3.43 g. Alginate fiber;

[0027] (3) Preparation of high antibacterial alginate dressing: the alginate fiber modified in step (2) is dried by a...

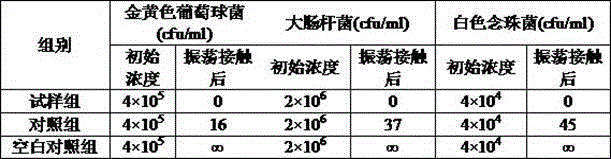

Embodiment 2

[0035] A preparation method of high antibacterial alginate dressing, the specific steps are as follows:

[0036] (1) Surface activation of alginate fibers: Cut 3.00 g of alginate fibers into short fibers with a length of 3-5 cm, add methanol to soak for 0.5 h, and ultrasonically treat them at 30°C for 60 minutes. Wash with deionized water several times, filter by suction and dry at room temperature;

[0037] (2) Functional modification of alginate fiber: add the surface activated alginate fiber in step (1) to 100 ml of 3-chloro-2-hydroxypropyltrimethylammonium chloride solution, and heat to 70 ℃, add 2 ml of an aqueous solution of 0.01 g of ferrous ammonium sulfate and 1.0 ml of 30% hydrogen peroxide to the reaction, and stir the reaction for 3 hours, wash with deionized water for several times, and vacuum at 50℃ After drying, 3.27 g of modified alginate fiber was obtained;

[0038] (3) Preparation of high antibacterial alginate dressing: the alginate fiber modified in step (2) is ...

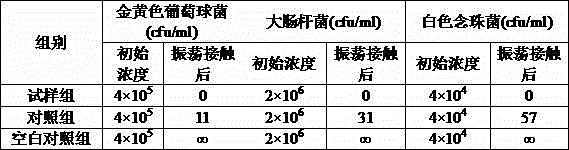

Embodiment 3

[0046] A preparation method of high antibacterial alginate dressing, the specific steps are as follows:

[0047] (1) Surface activation of alginate fibers: Cut 3.00 g of alginate fibers into short fibers with a length of 3-5 cm, soak them in acetone for 1 hour, and ultrasonically treat them at 20°C for 30 minutes. Wash with deionized water several times, filter by suction and dry at room temperature;

[0048] (2) Functional modification of alginate fibers: Add the surface activated alginate fibers in step (1) to 60 ml of methacryloxyethyltrimethylammonium chloride solution, and heat to 30°C. Add 5 ml of an aqueous solution with 0.9 g of cerium ammonium nitrate dissolved in it to react, and stir the reaction for 3 h, wash it with deionized water several times and then vacuum dry at 50°C to obtain 3.55 g of modified alginate fiber;

[0049] (3) Preparation of high antibacterial alginate dressing: the alginate fiber modified in step (2) is dried by acupuncture and hot press; after card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com