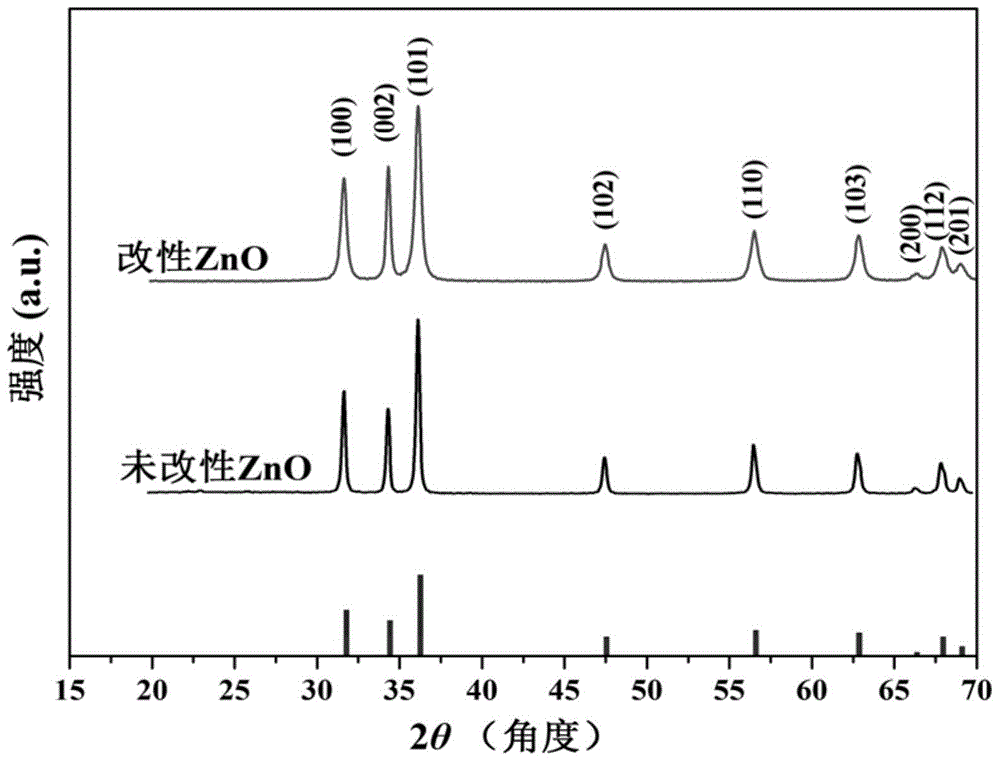

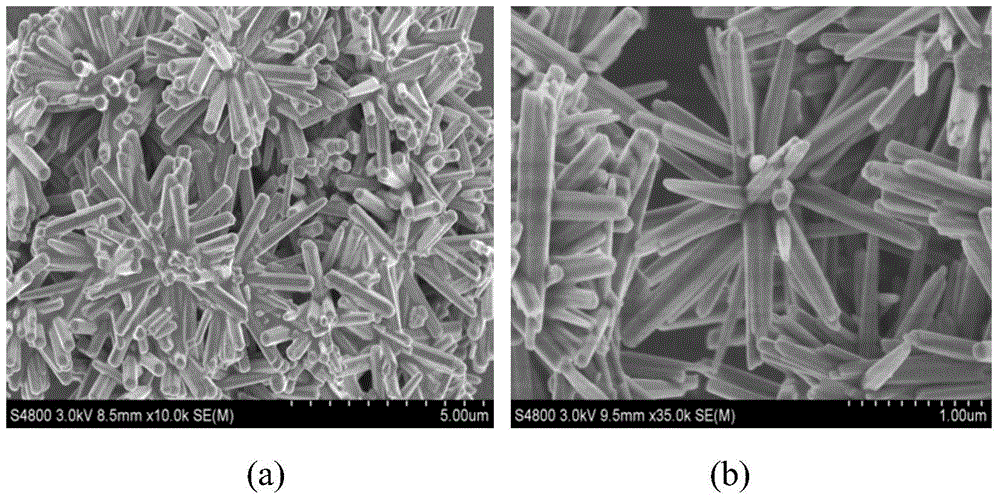

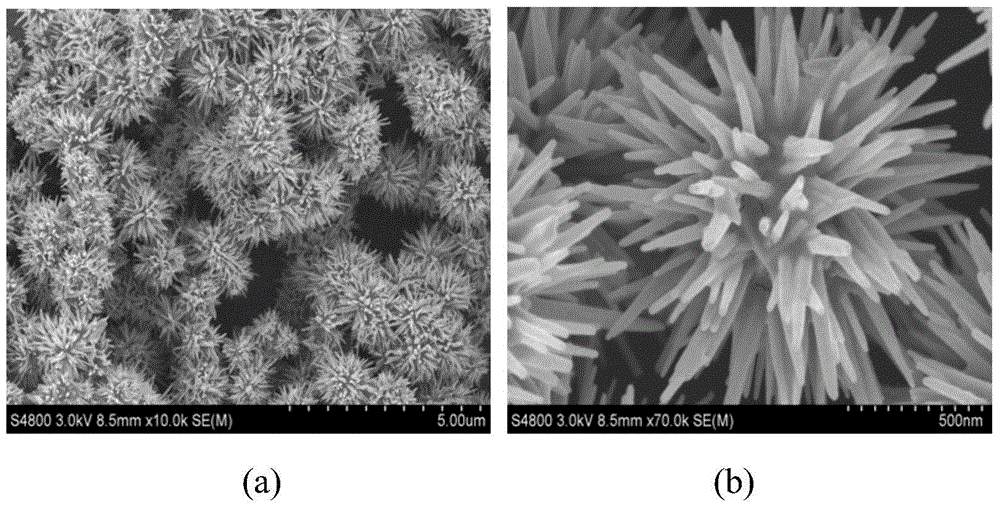

Sea urchin-shaped modified nanometer ZnO photocatalyst as well as preparation method and application of photocatalyst

A photocatalyst, sea urchin-like technology, applied in the field of materials, can solve problems such as poor photocatalytic degradation ability of Rhodamine B, and achieve the effects of economical and feasible raw materials, simple operation of process methods, and shortened time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Solution A: Measure 25 mL of zinc nitrate aqueous solution with a concentration of 0.6 mol / L, add 0.80 mmol of ferric nitrate nonahydrate to the above zinc nitrate aqueous solution, then add 230 mmol of sodium hydroxide, stir mechanically for 0.5 h, the solution becomes clear, and set aside.

[0029] Solution B: prepare a sodium lauryl sulfate solution with a concentration of 0.035mol / L, the solvent is a mixture of absolute ethanol and water, the volume ratio of alcohol to water (i.e. absolute ethanol:water) is 8:1, and the mechanical stirring is 0.5 h, stir well and set aside.

[0030] Measure 280mL of solution B and place it in a 500mL beaker. Under the action of mechanical stirring, slowly add solution A to the beaker dropwise for 20min, then mechanically stir for 2h, and then sonicate for 1h (200W). After the ultrasonication was completed, the liquid in the beaker was transferred to a 500mL three-neck flask with a stirring and condenser tube, and condensed and reflu...

Embodiment 2

[0032] Solution A: Measure 25 mL of zinc nitrate aqueous solution with a concentration of 0.55 mol / L, add 0.75 mmol of ferric nitrate nonahydrate to the above zinc nitrate aqueous solution, then add 250 mmol of sodium hydroxide, stir mechanically for 1 hour, the solution becomes clear, and set aside.

[0033]Solution B: Prepare a sodium lauryl sulfate solution with a concentration of 0.030mol / L. The solvent is a mixture of absolute ethanol and water. The volume ratio of alcohol to water is 6:1. Stir mechanically for 1 hour, stir evenly and set aside.

[0034] Measure 320mL of solution B into a 500mL beaker, slowly add solution A to the beaker dropwise under the action of mechanical stirring for 30min, then mechanically stir for 1h, and then sonicate for 0.5h (200W). After the ultrasonication was completed, the liquid in the beaker was transferred to a 500mL three-necked flask with a stirring and condenser tube, and condensed and refluxed in a water bath at 80°C for 3h. After t...

Embodiment 3

[0036] Solution A: Measure 25 mL of zinc nitrate aqueous solution with a concentration of 0.53 mol / L, add 0.65 mmol of ferric nitrate nonahydrate to the above zinc nitrate aqueous solution, then add 240 mmol of sodium hydroxide, stir mechanically for 0.5 h, the solution becomes clear, and set aside.

[0037] Solution B: prepare a sodium lauryl sulfate solution with a concentration of 0.028mol / L, the solvent is a mixture of absolute ethanol and water, the volume ratio of alcohol to water is 4:1, stir mechanically for 1 hour, stir well and set aside.

[0038] Take 290mL of solution B and place it in a 500mL beaker. Under the action of mechanical stirring, slowly add solution A to the beaker dropwise for 28min, then mechanically stir for 1h, and then sonicate for 0.5h (200W). After the ultrasonication was completed, the liquid in the beaker was transferred to a 500mL three-necked flask with a stirring and condenser tube, and condensed and refluxed in a water bath at 83°C for 3h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com