A kind of regeneration method of heavy metal chromium in chrome tanning sludge

A technology for heavy metals and sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

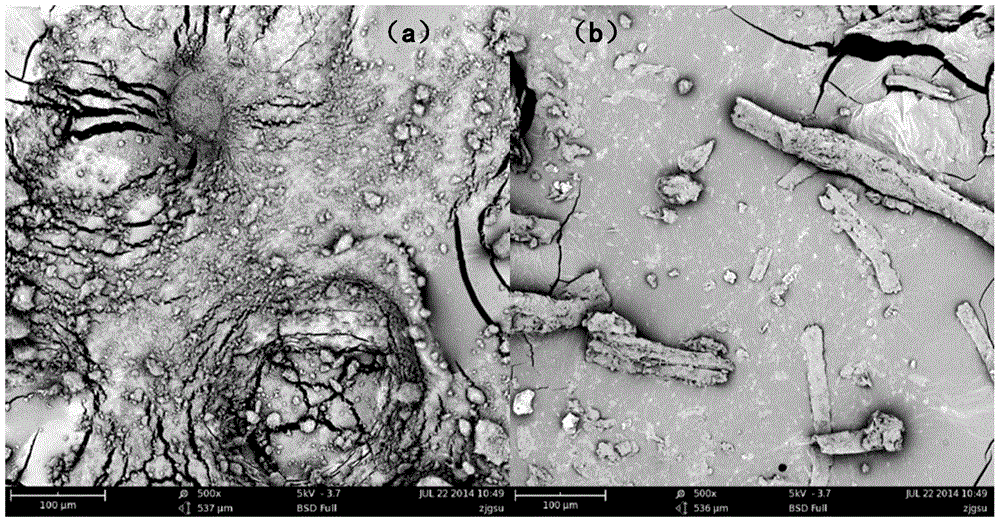

Image

Examples

Embodiment 1

[0044] A method for regenerating heavy metal chromium in chrome tanned sludge, comprising:

[0045] (1) Add chrome tanning sludge to hydrochloric acid with a concentration of 5mol / L, so that the solid-liquid ratio of chrome tanning sludge to hydrochloric acid is 10g / L, and react with stirring at 500rpm for 1.5h at 50°C, and the obtained The mixed solution is filtered through a 0.22 μm filter membrane to obtain a leaching solution, and the above steps are repeated for a second leaching;

[0046] (2) Using sodium bisulfite as a reducing agent, the Cr in the leaching solution 6+ reduced to Cr 3+ , sodium bisulfite and Cr 6+ The mass ratio is 5:1;

[0047] (3) Dilute the Cr containing Cr in step (2) with deionized water 3+ leaching solution, take 30mL containing Cr 3+ Add 0.7g of 732 sodium cation exchange resin to the leach solution with a concentration of 500mg / L for adsorption, and shake at 200rpm for 60min at 30°C;

[0048] (4) get 30mL mass concentration and be 8% hydro...

Embodiment 2

[0052] A method for regenerating heavy metal chromium in chrome tanned sludge, comprising:

[0053] (1) Add the chrome tanned sludge to hydrochloric acid with a concentration of 1mol / L, so that the solid-liquid ratio of the chrome tanned sludge to hydrochloric acid is 5g / L, and react with stirring at 500rpm for 1h at 40°C, and the obtained The mixed solution was filtered through a 0.22 μm filter membrane to obtain the leaching solution;

[0054] (2) Using sodium bisulfite as a reducing agent, the Cr in the leaching solution 6+ reduced to Cr 3+ , sodium bisulfite and Cr 6+ The mass ratio is 4:1;

[0055] (3) Dilute the Cr containing Cr in step (2) with deionized water 3+ leaching solution, take 30mL containing Cr 3+ Add 0.6g of 732 sodium cation exchange resin to the leachate with a concentration of 500mg / L for adsorption, and shake at 200rpm for 60min at 30°C;

[0056] (4) get 30mL mass concentration and be the sulfuric acid of 8% and load Cr in step (3) 3+ The resins w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com