Double-layer coated fertilizer and preparation method thereof

A double-layer coating and coating material technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problem that the mass concentration of superabsorbent resin should not be too large, the mechanical strength and film quality are difficult to control, and the outer coating layer The thickness adjustment is difficult to control and other problems, so as to achieve the effect of rapid drying of the film layer, short drying time and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

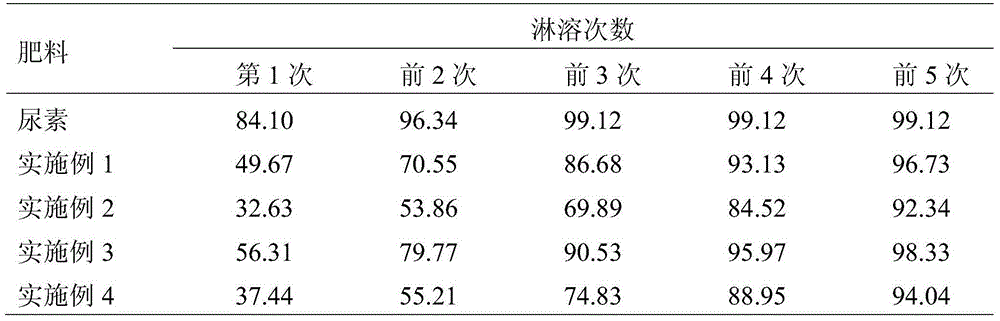

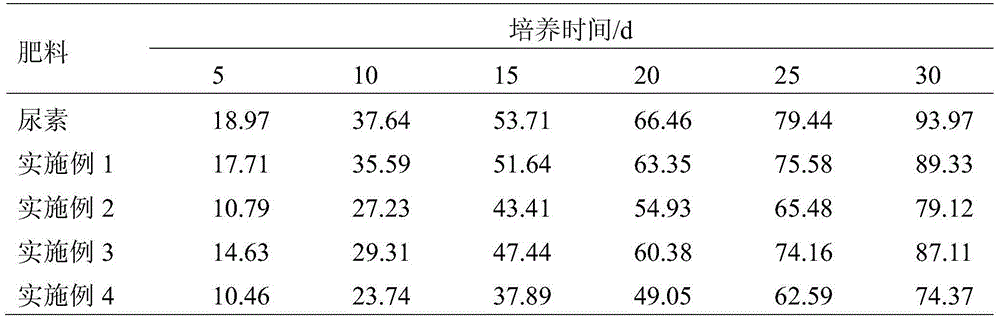

Examples

Embodiment 1

[0051] Embodiment 1, double-layer coated urea

[0052] Double-coated urea: use urea (particle size 3-5mm) as the core fertilizer, use No. 75 microcrystalline wax as the inner coating material (the amount is 1.0% of the urea mass), use cross-linked polyacrylate Powder (water-retaining agent) and alcohol-soluble thermoplastic acrylic resin (coating agent) are outer coating materials, the amount of cross-linked polyacrylate powder is 3% of the mass of urea, and the amount of alcohol-soluble thermoplastic acrylic resin is 20% of the mass of water-retaining agent %.

[0053] The coating agent solution used below is a 10% alcohol-soluble thermoplastic acrylic resin solution by mass percentage, which is an alcohol-soluble thermoplastic acrylic resin dissolved in ethanol and butyl acetate mixed solution and dibutyl phthalate (plasticizer) In 50~55℃ constant temperature water bath vibration accelerates the dissolution of alcohol-soluble thermoplastic acrylic resin, and the dissolution...

Embodiment 2

[0059] Embodiment 2, double-layer coated urea

[0060] Double-coated urea: the difference from Example 1 is that the amount of cross-linked polyacrylate powder is 9% of the mass of urea.

[0061] Prepared according to the method in Example 1, the difference from Example 1 is that the process of wrapping the outer coating material is carried out twice.

Embodiment 3

[0062] Embodiment 3, double-layer coated urea

[0063] Double-coated urea: use urea (particle size 3-5mm) as the core fertilizer, use No. 70 microcrystalline wax as the inner layer coating material (the amount used is 1.0% of the urea mass), and use starch grafted polyacrylate Powder (water-retaining agent) and polyacrylic acid resin (coating agent) are the outer coating materials, the dosage of starch-grafted polyacrylate powder is 3% of the mass of urea, and the dosage of polyacrylic resin is 20% of the mass of water-retaining agent.

[0064] The coating agent solution used is a polyacrylic acid resin solution with a mass percentage of 10%, which is a polyacrylic resin dissolved in a mixed solution of ethanol and water and dibutyl phthalate (plasticizer), at a constant temperature of 50 to 55°C Water-bath vibration accelerates the dissolution of polyacrylic acid resin, and the dissolution is complete; the mass ratio of polyacrylic acid resin to dibutyl phthalate (plasticizer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com