Magnetic nanohydrogel and preparation method thereof

A nano-hydrogel, magnetic nano-technology is applied in the field of nano-hydrogel to achieve the effects of improving magnetic signal, simple process and improving clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.9710g N,N-diethylacrylamide DEA, 0.0292g acrylic acid AA, 0.0603g N,N'-methylenebisacrylamide and 0.0502g sodium lauryl sulfate in 95g deionized water , and bubbling N at room temperature 2 Deoxygenation, magnetic stirring for 120 minutes;

[0032] (2) The reaction temperature rises to 70°C, under N 2 Insulate the above solution under protection for 30 minutes;

[0033] (3) then prepare the ammonium persulfate solution that mass concentration is 0.4%, get 4.9987g and add in the above-mentioned solution, keep N 2 atmosphere, continue to react for 4 hours;

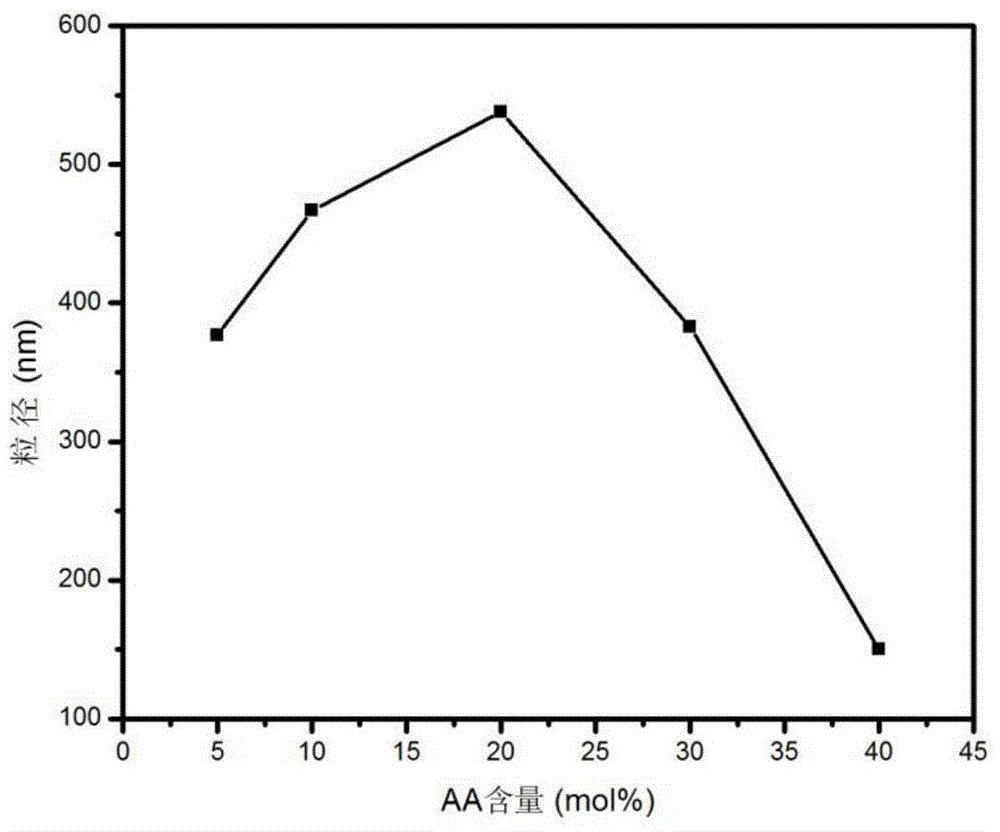

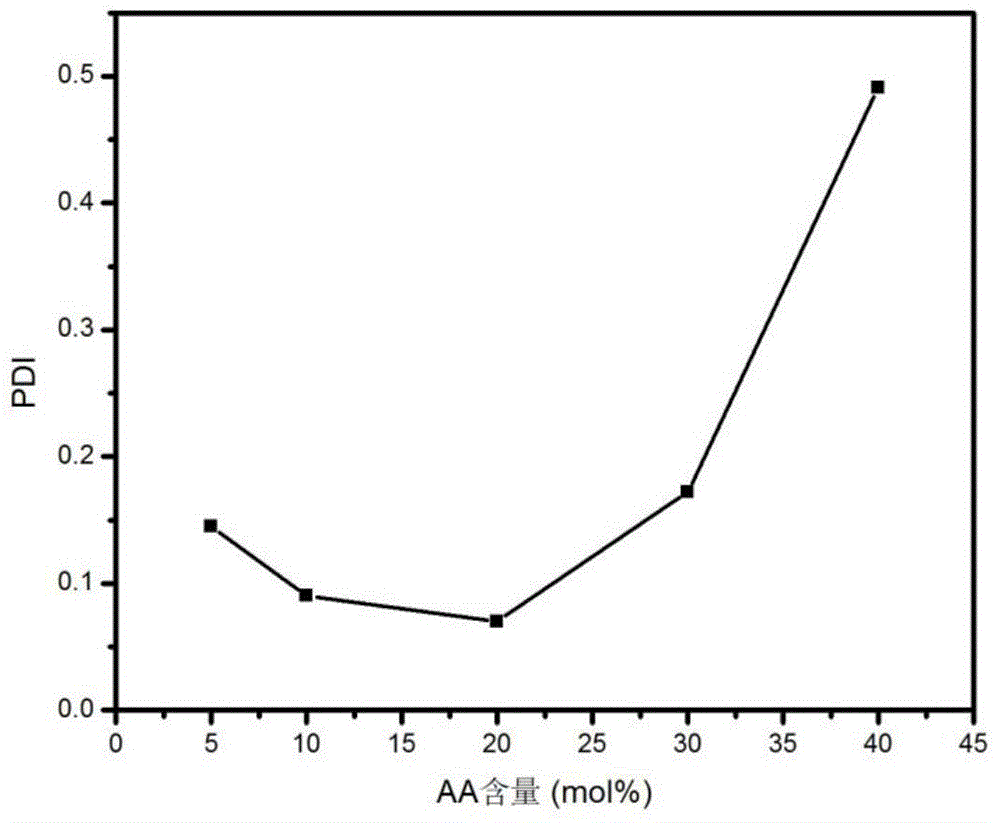

[0034](4) Then soak the obtained reactant in deionized water for dialysis for 4 days, change the water twice a day, remove the residual reaction raw materials and the electrolyte in the reaction system, the molecular weight cut-off of the dialysis bag used is 8000~14000, and the AA content is 5mol%. Copolymerized hydrogels were sampled for DLS testing.

Embodiment 2

[0036] (1) Dissolve 0.9409g DEA, 0.0587g AA, 0.0605g N,N'-methylene bisacrylamide and 0.0497g sodium lauryl sulfate in 95g deionized water, and blow N at room temperature 2 Deoxygenation, magnetic stirring for 120 minutes;

[0037] (2) The reaction temperature rises to 70°C, under N 2 Insulate the above solution under protection for 30 minutes;

[0038] (3) then prepare the ammonium persulfate solution that mass concentration is 0.4%, get 5.0004g and add in the above-mentioned solution, keep N 2 atmosphere, continue to react for 4 hours;

[0039] (4) Then soak the obtained reactant in deionized water for dialysis for 4 days, change the water twice a day, remove the residual reaction raw materials and the electrolyte in the reaction system, the molecular weight cut-off of the dialysis bag used is 8000~14000, and the AA content is 10mol%. Copolymerized hydrogels were sampled for DLS testing.

Embodiment 3

[0041] (1) Dissolve 0.1243g DEA, 0.8758g AA, 0.0601g N,N'-methylene bisacrylamide and 0.0502g sodium lauryl sulfate in 95g deionized water, and blow N at room temperature 2 Deoxygenation, magnetic stirring for 120 minutes;

[0042] (2) The reaction temperature rises to 70°C, under N 2 Insulate the above solution under protection for 30 minutes;

[0043] (3) then preparation mass concentration is the ammonium persulfate solution of 0.4%, gets 5.0006g and adds in the above-mentioned solution, keeps N 2 atmosphere, continue to react for 4 hours;

[0044] (4) Soak the obtained reactant in deionized water and dialyze for 4 days, change the water twice a day, remove the residual reaction raw materials and the electrolyte in the reaction system, the molecular weight cut-off of the dialysis bag used is 8000~14000, and the AA content is 20mol% Copolymerized hydrogels were sampled for DLS testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com