Filming solution of magnesium alloy black conversion film and preparation method of conversion film

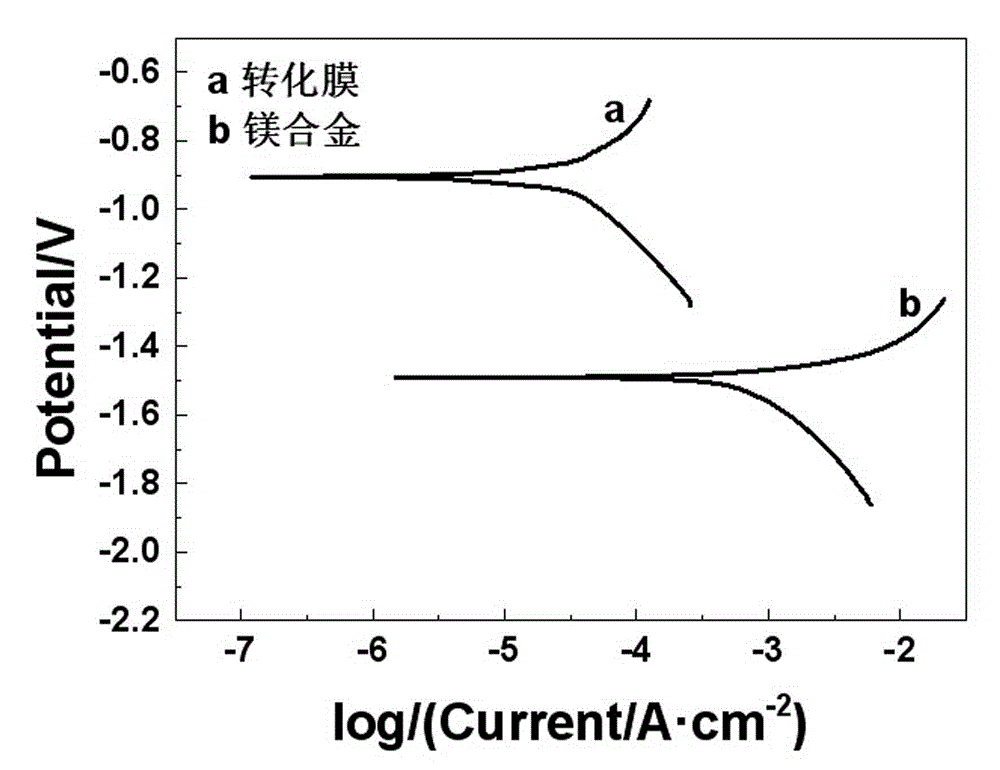

A conversion coating, magnesium alloy technology, applied in the direction of metal material coating process, can solve the problems of low corrosion resistance and negative electrode, and achieve the effect of improving corrosion resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Mechanical grinding

[0027] Grind the above magnesium alloy with 600#, 800#, 1000#, 1200# water-grinding sandpaper to expose the fresh magnesium alloy matrix, then rinse it with tap water or distilled water, and blow dry.

[0028] 2. Ultrasonic cleaning

[0029] Put the magnesium alloy sample into the acetone solution for ultrasonic cleaning (40KHz) to wash away the dirt on the surface.

[0030] 3. Alkaline washing

[0031] Put 40g of sodium phosphate, 10g of sodium carbonate, 50g of sodium hydroxide, and 5g of sodium silicate into 800mL of distilled water in turn. After all the substances are dissolved, add distilled water to 1L to make an alkali washing solution. Put the above-mentioned cleaned samples into the alkaline cleaning solution, the temperature is controlled at 80°C, and the time is 5 minutes. The samples were then rinsed with tap water and distilled water.

[0032] 4. Pickling

[0033] Immerse the above-mentioned alkali-washed sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com