Detergent for soldering tin and preparation method of detergent

A cleaning agent and solder technology, applied in the field of cleaning agents, can solve the problems of high requirements for processing equipment and processes, easy occupational diseases in the operating environment, and personal health hazards of operators, so as not to affect the solder connection strength and cleaning effect. Prominent, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

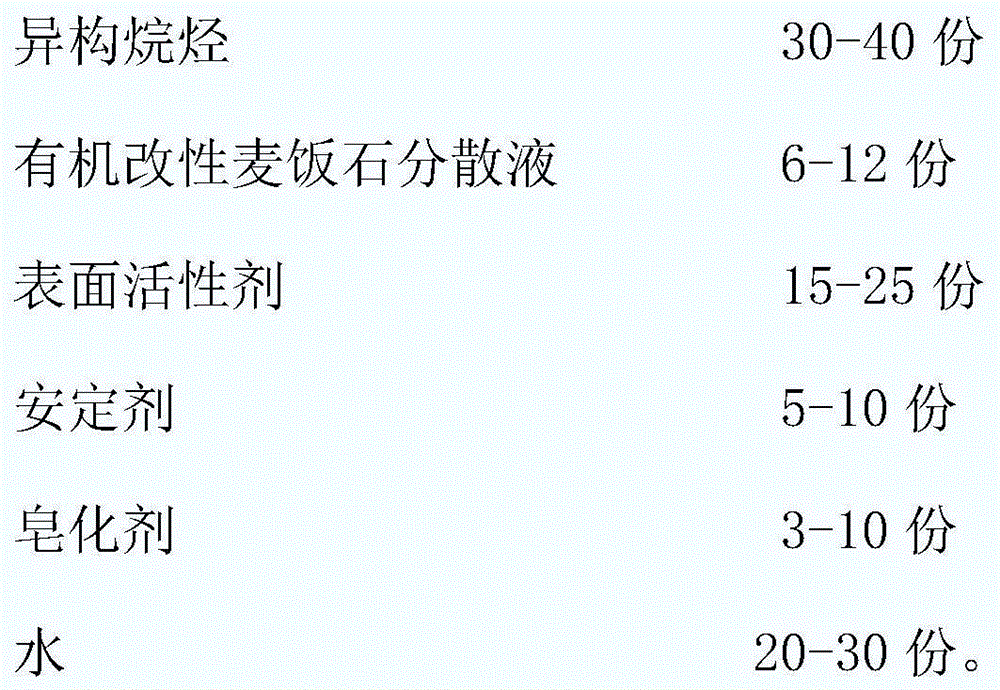

[0030] Embodiment 1 The cleaning agent for solder provided in this embodiment is made of the following components in percentage by weight:

[0031]

[0032] Further, the cleaning agent also includes any one or both of 3-5 parts of carboxymethyl chitosan oligosaccharide and 7-9 parts of water-soluble chitosan phosphate.

[0033] Further, the cleaning agent also includes any one or both of 2-4 parts of organosilicon quaternary ammonium salts, 3-8 parts of epoxy group quaternary ammonium salts, and 4-6 parts of epoxy organosilicon quaternary ammonium salts .

[0034] Further, the organically modified medical stone dispersion is obtained by dispersing organically modified medical stone in a mixture of absolute ethanol and DMF with a volume ratio of 1:1, and its concentration range is 1mg / ml- 3mg / ml.

[0035] Further, the raw material components and weight percentages of the organic modified medical stone are 3-8wt% medical stone, 82-95wt% deionized water, 0.5-1% sodium tripol...

Embodiment 2

[0048] The cleaning agent for solder provided in this embodiment and the preparation method thereof are basically the same as in Example 1, except that:

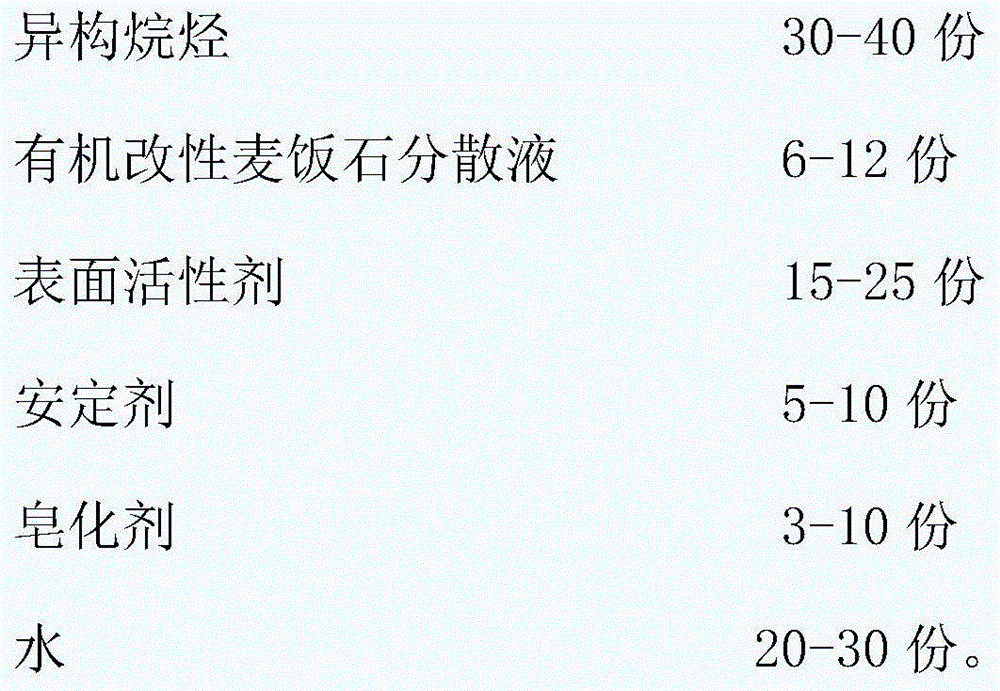

[0049] A cleaning agent for soldering tin, which is made of the following components in percentage by weight:

[0050]

[0051]

[0052] Further, the cleaning agent also includes 5 parts of carboxymethyl chitosan oligosaccharides and 2 parts of organic silicon quaternary ammonium salts.

[0053] Further, the organically modified medical stone dispersion is obtained by dispersing organically modified medical stone in a mixture of absolute ethanol and DMF with a volume ratio of 1:1, and its concentration range is 1 mg / ml.

[0054] Further, the raw material components and weight percentages of the organically modified medical stone are 8wt% medical stone, 95wt% deionized water, 1wt% sodium tripolyphosphate, and 5wt% organic modifier, wherein the wheat The rice stone is nano-scale medical stone powder with a particle diam...

Embodiment 3

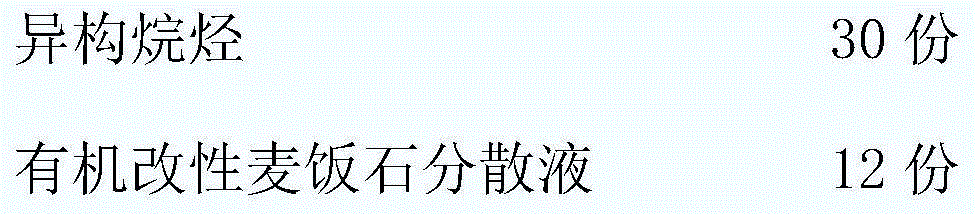

[0066] The cleaning agent for soldering tin provided in this embodiment and its preparation method are basically the same as those in Example 1-2, the difference being: the raw material components and their quality used in the cleaning agent for soldering tin and its preparation method Parts are different from Embodiment 1, 2, and other steps are identical with Embodiment 2; Soldering tin is used cleaning agent in the present embodiment, is made of the component of following percentage by weight:

[0067]

[0068] Further, the cleaning agent also includes 9 parts of water-soluble chitosan phosphate and 8 parts of epoxy quaternary ammonium salts.

[0069] Further, the concentration of the organically modified medical stone dispersion is 3mg / ml; the raw material components and weight percentages of organically modified medical stone are 3wt% of medical stone, 88wt% of deionized water, 0.5% trimerized Sodium phosphate, organic modifier 9wt%.

[0070] Further, the stabilizer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com