Low-residual and low-corrosivity aluminum soft soldering tin paste and manufacturing method thereof

An aluminum soldering and low-corrosion technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve problems such as large residue, uncertainty, and corrosion of solder joints, and achieve good storage, low corrosion, and welding Effect with little residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

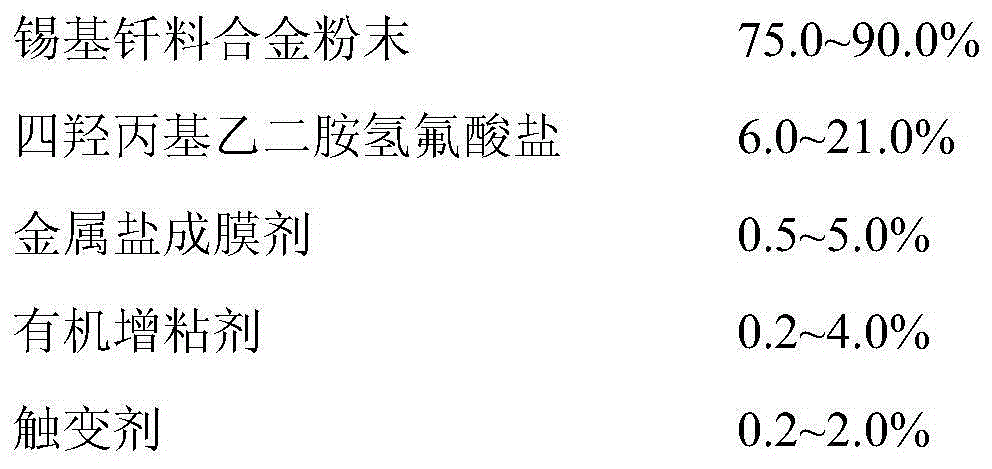

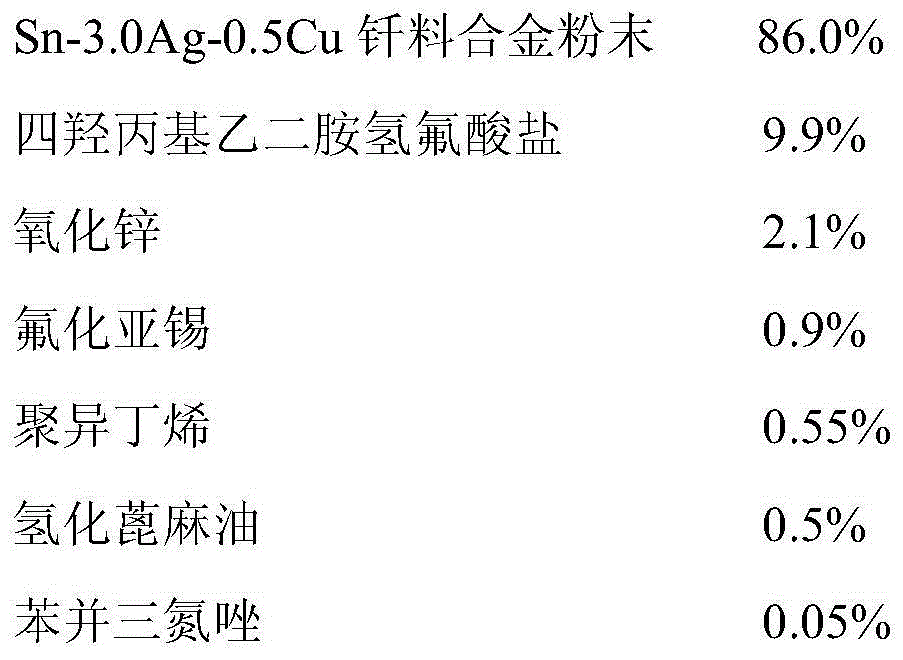

[0037] A low-residue and low-corrosion aluminum soldering solder paste, the solder alloy powder is Sn3.0Ag0.5Cu, and the components in the solder paste are as follows by weight percentage:

[0038]

[0039] Preparation method: dilute tetrahydroxypropyl ethylenediamine and hydrofluoric acid with absolute ethanol to about 60% and 30% mass fraction respectively; gradually drop the diluted hydrofluoric acid into the diluted tetrahydroxypropyl ethyl diamine solution until the pH is 5.5; then the titrated solution was evaporated at 120°C for 2 hours, and tetrahydroxypropylethylenediamine hydrofluoride was obtained after cooling.

[0040] Weigh 99.0 grams of hydroxypropyl ethylenediamine hydrofluoride and put it into the reaction kettle, heat it to 150 ° C, make it melt completely and keep the temperature constant; then add 21.0 grams of zinc oxide, fluoride 9.0 grams of tin, 5.5 grams of polyisobutylene, 5.0 grams of hydrogenated castor oil, 0.5 grams of benzotriazole, stir evenl...

Embodiment 2

[0042] A low-residue and low-corrosion aluminum soldering solder paste, the solder alloy powder is Sn-58Bi, and the components in the solder paste are as follows by weight percentage:

[0043]

[0044] Preparation method: Dilute tetrahydroxypropylethylenediamine and hydrofluoric acid with absolute ethanol to a mass concentration of 40% and 15% respectively; gradually drop diluted hydrofluoric acid into diluted tetrahydroxypropylethylenediamine amine solution until the pH is 7.0; then the titrated solution was evaporated at 100°C for 5 hours, and tetrahydroxypropylethylenediamine hydrofluoride was obtained after cooling.

[0045] Weigh 210.0 grams of hydroxypropyl ethylenediamine hydrofluoride and put it into the reaction kettle, heat it to 135 ° C, make it melt completely and keep the temperature constant, then add 15.0 grams of zinc fluoride, boron fluoride to the molten acid ammonium salt 15.0 grams of stannous chloride, 5.0 grams of polyethylene glycol 200, 2.5 grams of ...

Embodiment 3

[0047] A low-residue and low-corrosion aluminum soldering solder paste, the solder alloy powder is Sn-37Pb, and the components in the solder paste are as follows by weight percentage:

[0048]

[0049] Preparation method: Dilute tetrahydroxypropyl ethylenediamine and hydrofluoric acid with absolute ethanol to a mass concentration of 50% and 22% respectively; gradually drop the diluted hydrofluoric acid into the diluted tetrahydroxypropyl ethylenediamine amine solution until the pH is 6.5; then the titrated solution was evaporated at 110°C for 3.5 hours, and tetrahydroxypropylethylenediamine hydrofluoride was obtained after cooling. Weigh 65.0 grams of hydroxypropylethylenediamine hydrofluoride and put it into the reaction kettle, heat it to 120°C, make it melt completely and keep the temperature constant, then add 10.0 grams of zinc fluoroborate, chloride 5.0 grams of zinc, 9.0 grams of tin bromide, 5.0 grams of polyethylene glycol 1000, 5.0 grams of polyethylene wax, and 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com