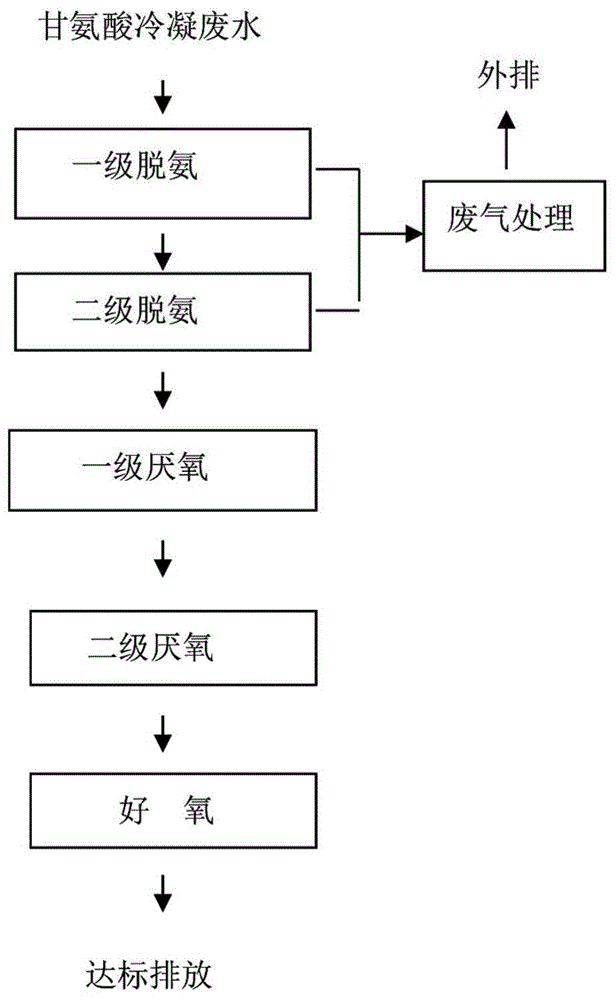

Treatment process of glycine condensation wastewater

A technology for condensing wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, ammonia compounds, etc. It can solve the problem that condensed wastewater cannot meet the discharge standard, and achieve low pharmaceutical costs and strong adsorption capacity. , the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

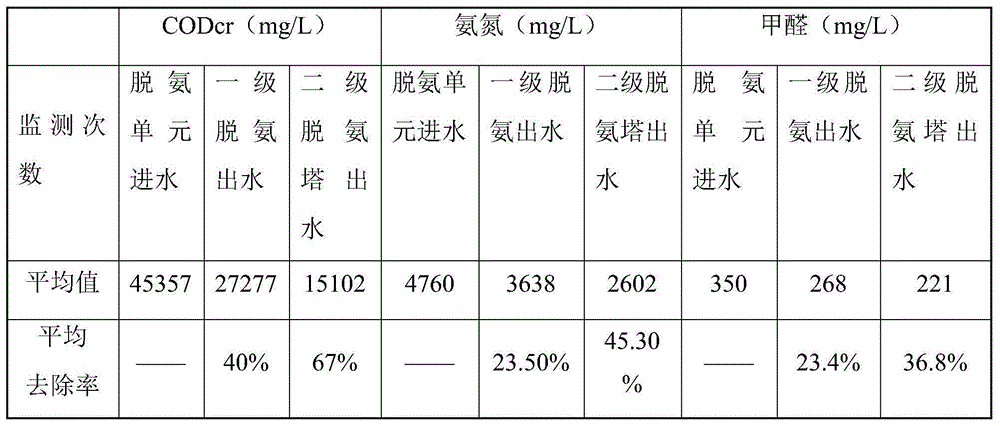

[0026] Pilot test of deammonification pretreatment of glycine condensate wastewater, with a treatment capacity of 1 ton / h. The removal effect of the deamination unit on pollutants is shown in Table 1.

[0027] Table 1. Removal effect of pollutants by deamination unit

[0028]

[0029] Known from Table 1: the two-stage removal is 45.3%, and the removal rate of formaldehyde is 36.8%. The deamination process is carried out under the original temperature of 34-40 degrees Celsius and the original pH condition (9-10) of the wastewater. The wastewater pretreated by the deamination unit can directly enter the biochemical unit for further treatment.

Embodiment 2

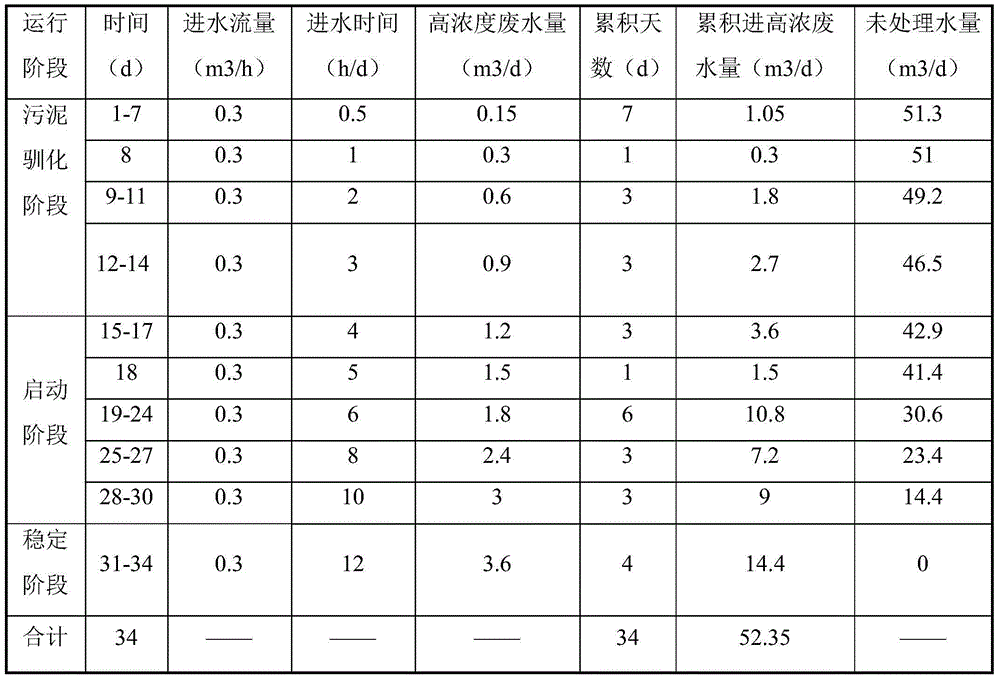

[0031] Pilot test of anaerobic treatment of glycine condensate wastewater. The processing capacity is 0.3 tons / h.

[0032] About 13 tons of muddy water discharged from the sludge digestion tank in the sludge treatment system of the biochemical sewage treatment plant was taken as the inoculation sludge for this pilot test. Each of the primary and secondary EGSB reactors was inoculated with 6.5 tons of sludge, diluted with an appropriate amount of water from the lower sump, and then pumped into the reactor tank. Turn on the reflux pump. After three days of cultivation, more air bubbles were observed on the filling top. On the fourth day, a small amount of waste water was introduced. Add 10kg of sugar to each of the two-stage anaerobic reactors on the 1-27th day, and pump the sugar from the sump at the lower part of the reactor after melting. No more sugar after day 28. The pH value in the reaction zone of the EGSB anaerobic reactor is measured every day in the range of 6.5-8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com