Antibacterial waterproof polyurethane coating and preparation method thereof

A polyurethane coating, polyester polyol technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc., can solve problems such as poor overall performance, improve waterproof effect, reduce solid content, improve The effect of low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

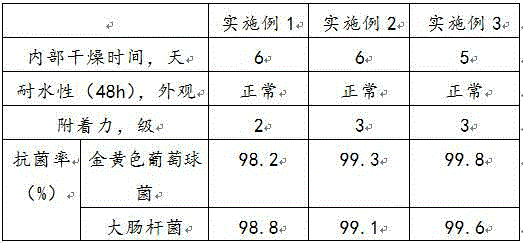

Examples

Embodiment 1

[0017] An antibacterial and waterproof polyurethane coating, prepared from the following raw materials in parts by weight (kg): polyester polyol 150, 1,6-hexamethylene diisocyanate 15, isophorone diisocyanate 25, 2,2-dimethylol Propionic acid 10, triethylamine 20, nano silver 10, citrate 7, kaolin 10, propylene glycol 7, neopentyl glycol diacrylate 5, organic bismuth 3, dibutyltin dilaurate 7, diethanolamine diacetone Propionamide 3, polydimethoxysiloxane 6, nano-titanium dioxide 8, lauryl polyoxyethylene ether 12, acetone 18, sodium dodecylsulfonate 0.6, triethylene thiophosphoramide 40, additives 9;

[0018] The additive is made of the following raw materials in parts by weight (kg): fumed silica 13, acrylic acid 4, barium sulfate 6, ethylenediamine 7, benzoin 1, epoxy resin 7, fluorine leveling agent 9, chlorine Chemical paraffin 8, titanium dioxide 6, ultraviolet absorber 8, antioxidant CA 4; the preparation method is: take the above-mentioned parts by weight of fumed sil...

Embodiment 2

[0025] An antibacterial and waterproof polyurethane coating prepared from the following raw materials in parts by weight (kg): polyester polyol 165, 1,6-hexamethylene diisocyanate 17.5, isophorone diisocyanate 27.5, 2,2-dimethylol Propionic acid 12, triethylamine 22.5, nano silver 11, citrate 8, kaolin 11, propylene glycol 8, neopentyl glycol diacrylate 6, organic bismuth 4, dibutyltin dilaurate 8, diethanolamine diacetone Propionamide 3.5, polydimethoxysiloxane 6.5, nano-titanium dioxide 8.5, lauryl polyoxyethylene ether 13, acetone 19, sodium dodecylsulfonate 0.7, triethylenethiophosphoramide 45, additives 9.5;

[0026] The additive is made of the following raw materials in parts by weight (kg): fumed silica 14, acrylic acid 4.5, barium sulfate 7, ethylenediamine 8, benzoin 2, epoxy resin 8, fluorine leveling agent 9.5, chlorine Chemical paraffin 10, titanium dioxide 8, ultraviolet absorber 9, antioxidant CA 5; the preparation method is: take the above-mentioned parts by we...

Embodiment 3

[0029] An antibacterial and waterproof polyurethane coating, prepared from the following raw materials in parts by weight (kg): polyester polyol 180, 1,6-hexamethylene diisocyanate 20, isophorone diisocyanate 30, 2,2-dimethylol Propionic acid 14, triethylamine 25, nano silver 12, citrate 9, kaolin 12, propylene glycol 9, neopentyl glycol diacrylate 7, organic bismuth 5, dibutyltin dilaurate 9, diethanolamine diacetone Propionamide 4, polydimethoxysiloxane 7, nano-titanium dioxide 9, polyoxyethylene lauryl ether 14, acetone 20, sodium dodecylsulfonate 0.8, triethylenethiophosphoramide 50, additives 10;

[0030] The additive is made of the following raw materials in parts by weight (kg): fumed silica 15, acrylic acid 5, barium sulfate 8, ethylenediamine 9, benzoin 3, epoxy resin 9, fluorine leveling agent 10, chlorine Chemical paraffin 12, titanium dioxide 10, ultraviolet absorber 10, antioxidant CA 6; the preparation method is: take the above-mentioned parts by weight of fumed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com