Composite channel MHEMT (Metamorphic High Electron Mobility Transistor) microwave oscillator and preparation method thereof

A microwave oscillator and composite channel technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of limiting the development of HEMT devices on GaAs substrates, high manufacturing costs of InP substrates, and small dynamic range of devices. Achieve strong practicability and utilization value, enhance the concentration of two-dimensional electron gas and electron mobility, and achieve the effect of low phase noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A preparation method of a composite channel MHEMT microwave oscillator, comprising the steps of:

[0033] Step 1: Epitaxial material growth.

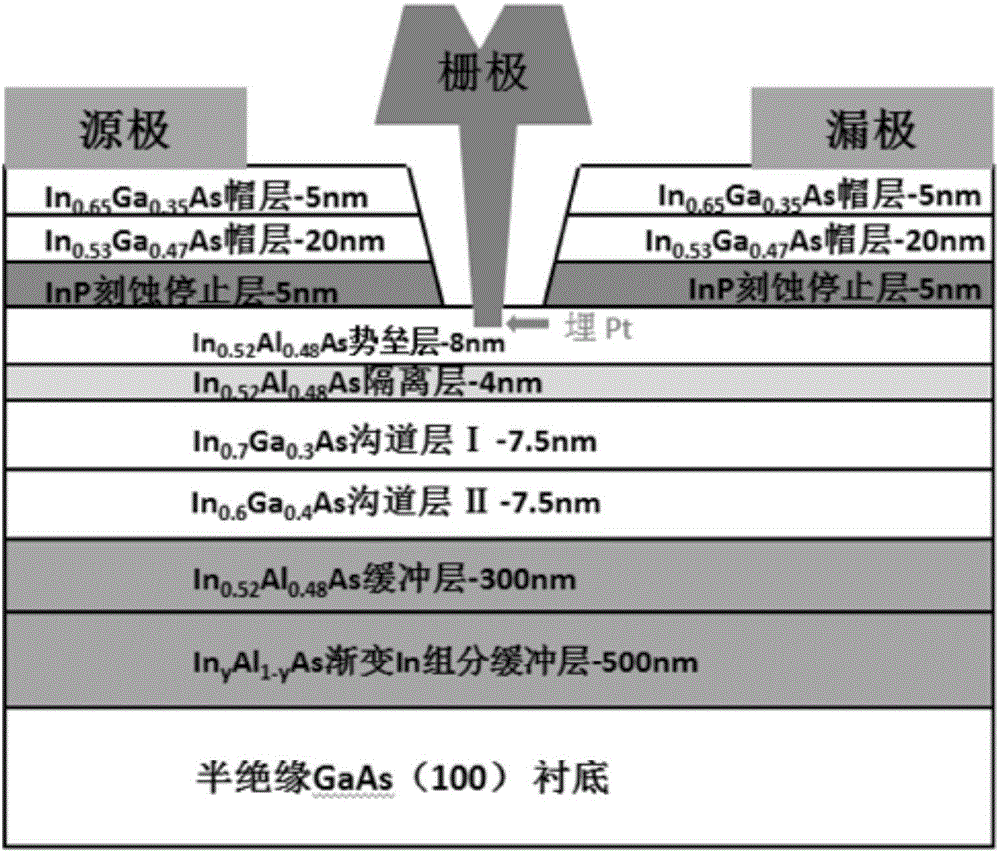

[0034] On the GaAs semi-insulating substrate layer, a 500nm variable In composition InAlAs buffer layer and a 300nm In 0.52 al 0.48 As buffer layer, 7.5nm In 0.6 Ga 0.4 As conductive channel layer, 7.5nm In 0.7 Ga 0.3 As conductive channel layer, 4nm In 0.52 al 0.48 As isolation layer, 8nm In 0.52 al 0.48 As barrier layer, 5nm InP etch stop layer, 20nm In 0.53 Ga 0.47 As cap layer, 5nm In 0.65 Ga 0.35 The As cap layer forms a GaAs substrate variable composition epitaxial material structure. see figure 1 It is a structural diagram of a composite channel GaAs substrate variable composition epitaxial material.

[0035] Step 2: device isolation is formed.

[0036]Uniform photolithography to protect the table. First, the surface of the sample was pretreated with HMDS in order to enhance the adhesion of the photoresist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com