Negative photosensitive resin composition

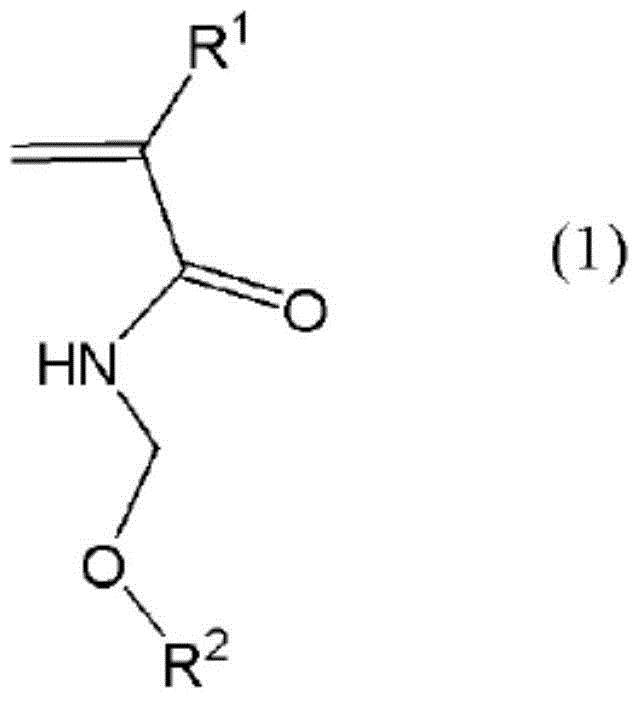

A technology of photosensitive resin and composition, which is applied in the field of cured film and negative photosensitive resin composition, which can solve the problems of poor pattern formation and development, lower storage stability, etc., and achieve the effect of high sensitivity and small shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] Hereafter, although an Example is given and this invention is demonstrated in more detail, this invention is not limited to these Examples.

[0136] [Abbreviated symbols used in Examples]

[0137] The meanings of the abbreviations used in the following examples are as follows.

[0138] MAA: methacrylic acid

[0139] MI: maleimide

[0140] MMA: methyl methacrylate

[0141] BMAA: N-Butoxymethacrylamide

[0142] HEMA: 2-Hydroxyethyl methacrylate

[0143] ST: Styrene

[0144] AIBN: Azobisisobutyronitrile

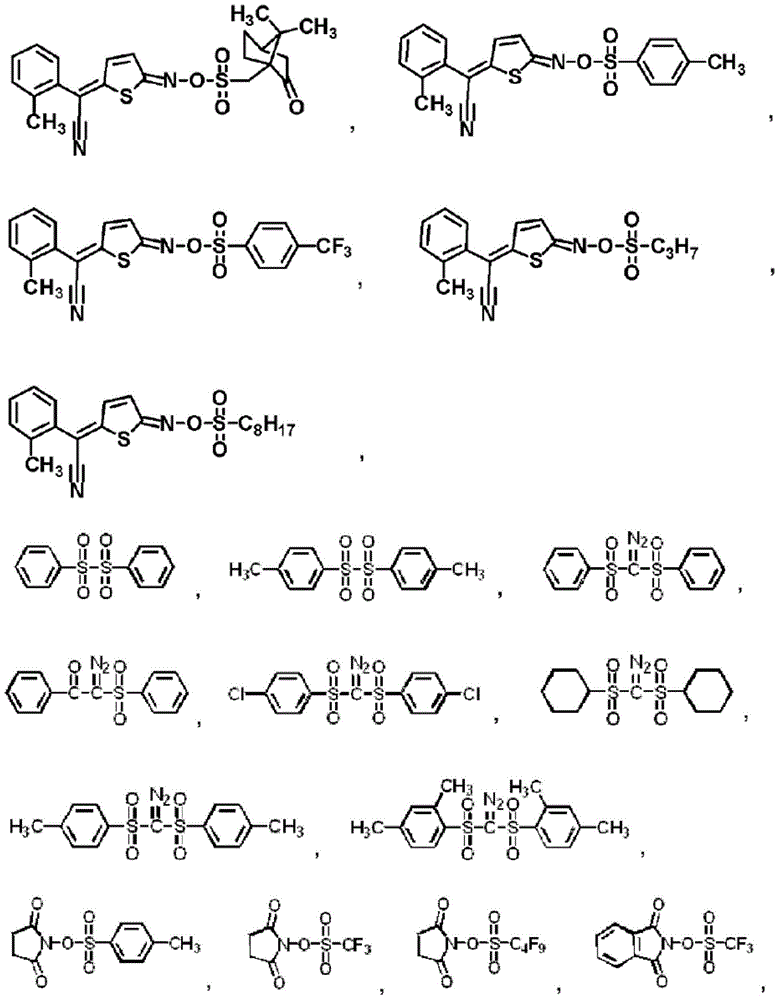

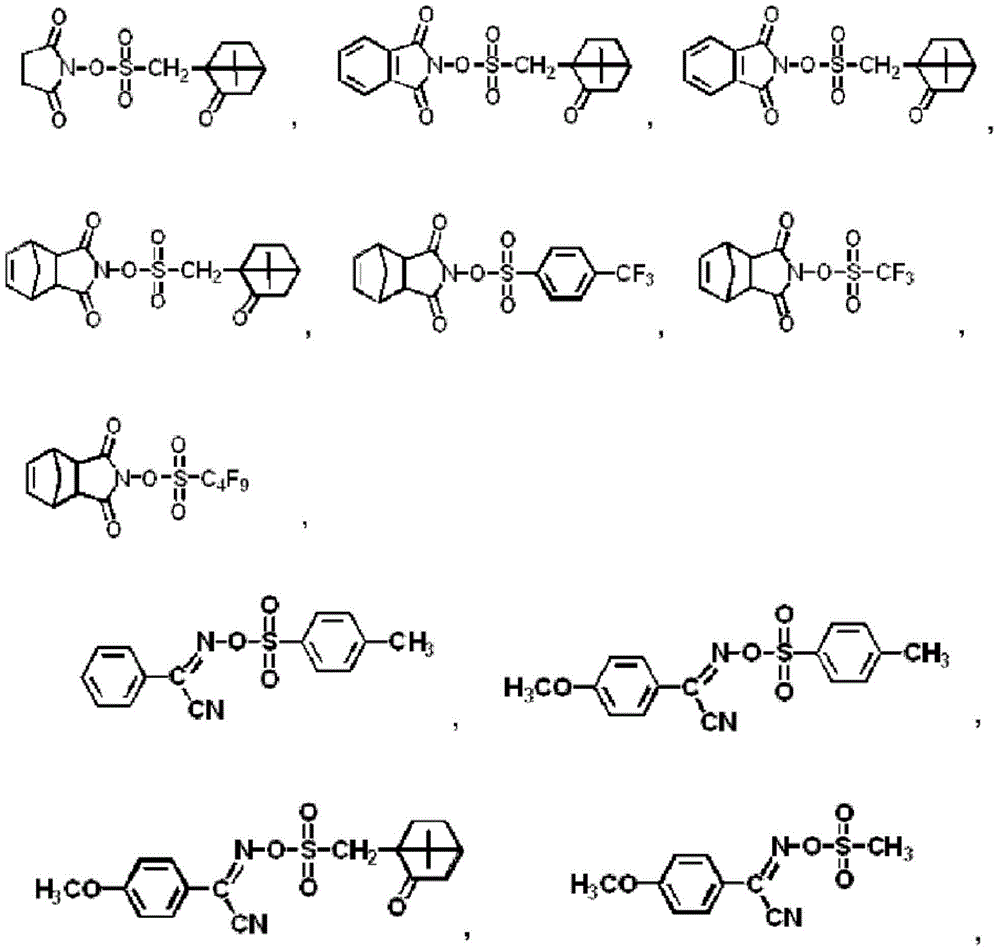

[0145] PRG1: 1-(4-phenylthiophenyl)-1,2-octanedione-2-(O-benzoyl oxime)

[0146] PRG2: Diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide

[0147] HPC: Hydroxypropyl Cellulose

[0148] DPHA: dipentaerythritol penta / hexaacrylate

[0149] PETA: pentaerythritol triacrylate

[0150] PTSM: Morpholinate p-toluenesulfonate

[0151] PGME: Propylene Glycol Monomethyl Ether

[0152] PGMEA: Propylene Glycol Monomethyl Ether Acetate

[0153] CYM: Cymel 303 (manufactured by...

Synthetic example 1

[0157] As monomer components constituting the copolymer, MI (20.0g), BMAA (34.6g), ST (22.3g) were used, AIBN (4g) was used as a radical polymerization initiator, and they were carried out in a solvent PGME (150g). A polymerization reaction was carried out to obtain a copolymer solution (copolymer concentration: 35% by mass) of Mn5,200 and Mw12,000 (P1). In addition, the polymerization temperature is adjusted to a temperature of 60°C to 90°C.

Synthetic example 2

[0159] As the monomer components constituting the copolymer, use MAA (6.5g), BMAA (16.3g), ST (9.8g), use AIBN (1.8g) as a radical polymerization initiator, and make them in the solvent PGME (64g) A polymerization reaction was performed to obtain a copolymer solution (copolymer concentration: 30% by mass) of Mn6,000 and Mw12,000 (P2). In addition, the polymerization temperature is adjusted to a temperature of 60°C to 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com