Treatment process method and device for high-salinity and high-ammonia-nitrogen rare-earth production wastewater

A technology for production wastewater and treatment process, which is applied in mining wastewater treatment, metallurgical wastewater treatment, multi-stage water treatment, etc. The reduction of energy consumption and oxygen supply, significant economic benefits, and the effect of a broad application market

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

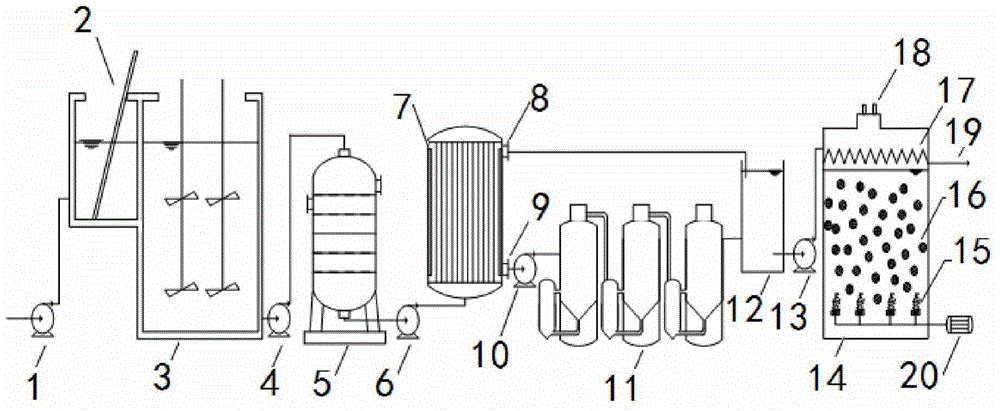

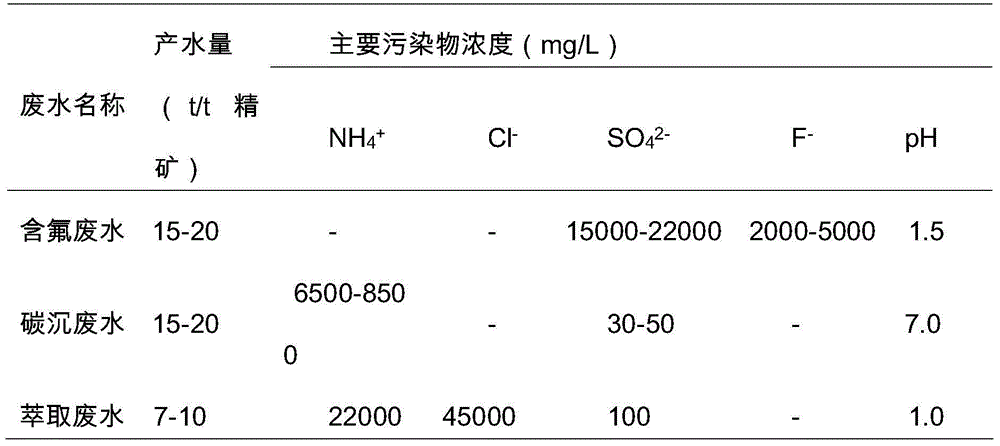

[0025] Embodiment 1: as figure 1 as shown,

[0026] A treatment process device for high-salinity, high-ammonia-nitrogen, rare earth production wastewater. Inlet pump 1 is connected to artificial fine grid 2, artificial fine grid 2 is connected to underground regulating tank 3, underground regulating tank 3 is connected to lift pump 4, and the outlet of lift pump 4 The pipeline is connected to the top of the multimedia filter 5, the lower part of the multimedia filter 5 is connected to the first water inlet pump 6, the outlet pipe of the first water inlet pump 6 is connected to the electrodialysis device 7, and the upper part of the electrodialysis device 7 is connected to the desalination liquid outlet pipeline 8. The lower part of the electrodialysis device 7 is connected to the concentrated solution outlet pipeline 9, the desalinated solution outlet pipeline 8 is connected to the water storage tank 12, the concentrated solution outlet pipeline 9 is connected to the water inl...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, the process of electrodialysis, three-effect concentrated crystallization and integrated anammox process of the present invention to treat rare earth production wastewater consists of an electrodialysis device, a three-effect concentrated crystallizer, a water storage tank and an integrated anammox reactor composition. The volume of the water storage tank is 20m 3 , the volume of the integrated anammox reactor is 100m 3 . Use an air compressor for aeration.

[0043] The influent water used in the example is the carbon precipitation effluent in the rare earth production wastewater treatment process, which is taken from the production workshop in Inner Mongolia. Its water quality is: pH 7.11, ammonia nitrogen 4103mg / L, COD 1260mg / L, alkalinity 298mg / L (calculated as calcium carbonate), and TDS 32500mg / L.

[0044] Utilize the operation method step of above-mentioned device as follows:

[0045] Step 1. Inoculation sludge: The inocul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com