Polyaspartic acid type grafted copolymer and preparation method thereof

A technology of polyaspartic acid and graft copolymer is applied in the field of preparation of polyaspartic acid freezing point regulators, which can solve the problems of large consumption of ethylene glycol, unfavorable environmental protection, inability to repair, etc., and achieves low production cost, The effect of easy industrial production and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

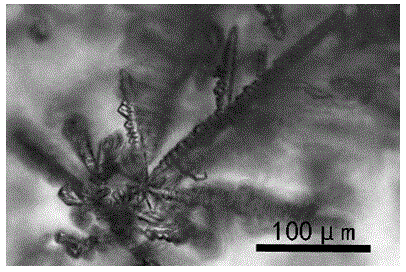

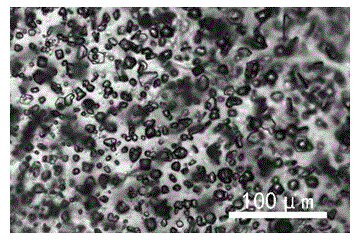

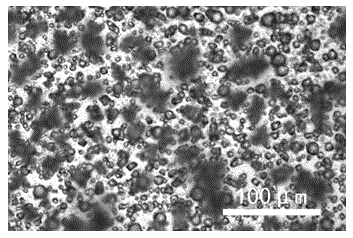

Image

Examples

Embodiment 1

[0046] First, dissolve 1g of polysuccinimide in a reaction bottle of 10mL N,N-dimethylformamide. After it is completely dissolved, add polysuccinimide and ethanolamine to ethanolamine at a molar ratio of 1:1, seal it, and place it in an oil bath. Heat to 60°C, carry out ammonolysis with stirring for 48 hours, after the reaction is completed, add 0.4g / mL NaOH1mL according to the grafting ratio, a viscous fluid is precipitated at the bottom, discard the upper layer of reddish-brown liquid, dissolve the lower layer of fluid with water, and add HCl to adjust the pH When the value reaches neutral, dialyze for 3 days and freeze-dry for 24 hours to obtain a light yellow solid powder, which is PAsp / EA-1.0.

Embodiment 2

[0048] First, dissolve 1 g of polysuccinimide in a reaction bottle of 5 mL of N,N-dimethylformamide. After it is completely dissolved, add polysuccinimide and ethanolamine to ethanolamine at a molar ratio of 1:0.8, seal it, and place it in an oil bath. Heat to 60°C, carry out ammonolysis with stirring for 24 hours, after the reaction is completed, add 0.4g / mL NaOH 0.8mL according to the graft ratio, a viscous fluid precipitates at the bottom, discard the upper reddish-brown liquid, dissolve the lower fluid with water, add HCl Adjust the pH value to neutral, dialyze for 3 days, and freeze-dry for 24 hours to obtain a light yellow solid powder, namely PAsp / EA-0.8.

Embodiment 3

[0050] First, dissolve 1 g of polysuccinimide in a reaction bottle of 5 mL of N,N-dimethylformamide. After it is completely dissolved, add polysuccinimide and ethanolamine to ethanolamine at a molar ratio of 1:0.6, seal it, and place it in an oil bath. Heat to 60°C, carry out ammonolysis with stirring for 24 hours, after the reaction is completed, add 0.4g / mL NaOH 0.6mL according to the grafting ratio, a viscous fluid precipitates at the bottom, discard the upper reddish-brown liquid, dissolve the lower fluid with water, add HCl Adjust the pH value to neutral, dialyze for 3 days, and freeze-dry for 24 hours to obtain a light yellow solid powder, ie PAsp / EA-0.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com