Novel aluminum and high-molecular aluminum alloy chromium-free film forming agent

An aluminum alloy and polymer technology, which is applied in the field of new aluminum and aluminum alloy polymer chromium-free film formers, can solve the problems of difficulty in meeting the requirements of architectural aluminum profiles, complicated processing technology, and long processing time, and achieve excellent film forming effects. , low price, short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

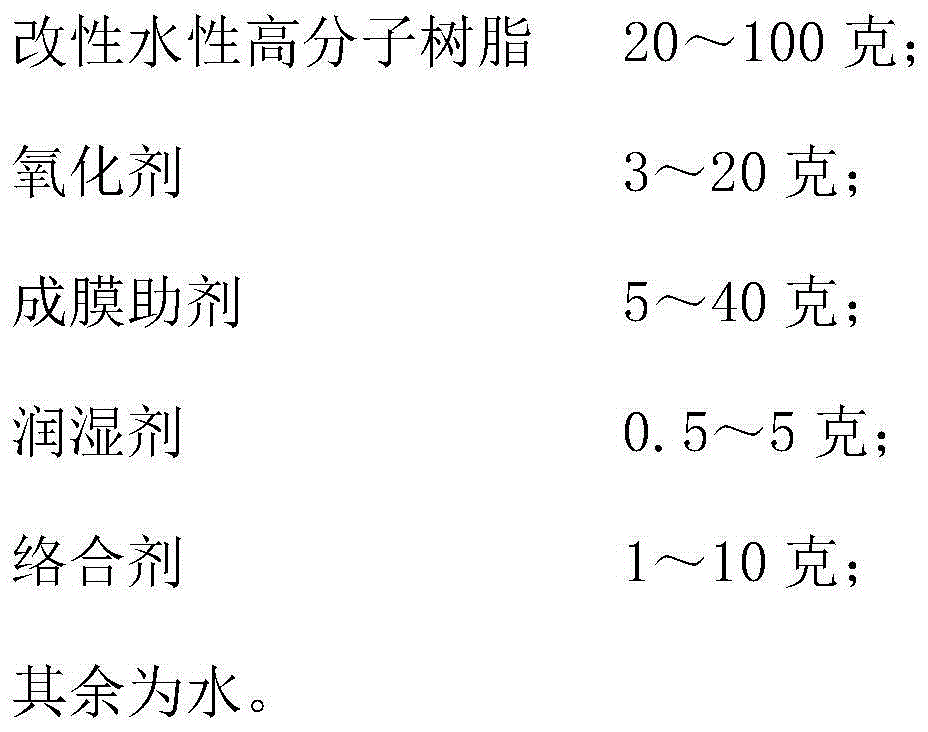

[0027] A new type of aluminum and aluminum alloy polymer chromium-free film-forming agent, which takes the following weight composition and components:

[0028]

[0029] Add 800 ml of water, stir well to dissolve and mix evenly, add appropriate amount of water and mix evenly to prepare 1 liter of film-forming agent.

[0030] Dilute the above-mentioned film-forming agent with water, prepare it with a volume ratio of film-forming agent to water of 1:20, and adjust the pH to 2-4 with triethanolamine.

[0031] When using the film-forming agent described in this embodiment, first clean the aluminum workpiece with an acidic or neutral cleaning agent to remove oil and dust on the surface of the aluminum, then clean other substances remaining on the surface of the aluminum with water, and then use this The film-forming agent described in the embodiment is treated at room temperature for 2 to 5 minutes to form a conversion film on the surface of the aluminum material, and finally th...

Embodiment 2

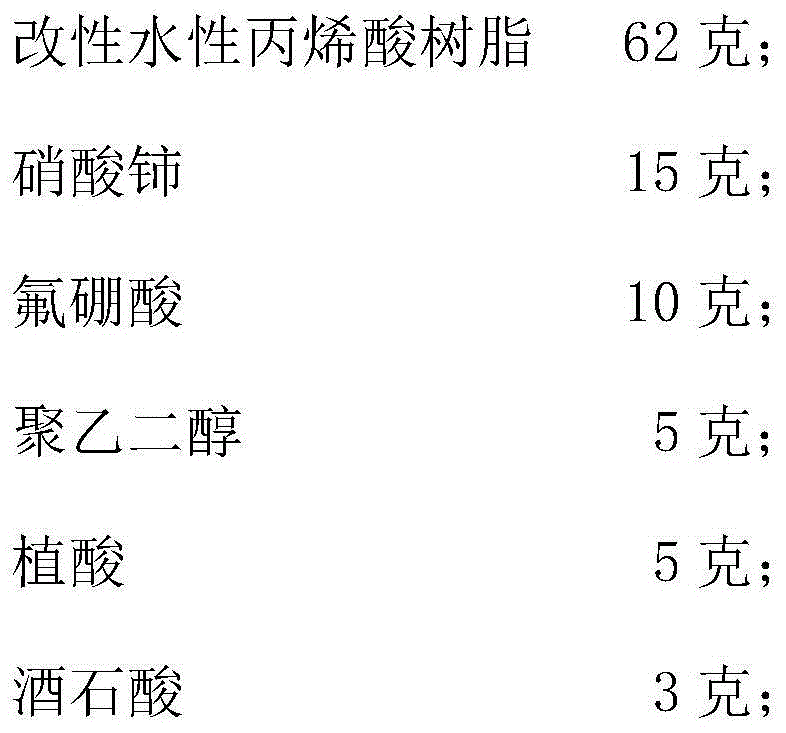

[0034] A new type of aluminum and aluminum alloy polymer chromium-free film-forming agent, which takes the following weight composition and components:

[0035]

[0036] Add 800 ml of water, stir well to dissolve and mix evenly, add appropriate amount of water and mix evenly to prepare 1 liter of film-forming agent.

[0037] Dilute the above-mentioned film-forming agent with water, prepare the film-forming agent to water volume ratio of 1:10, and adjust the pH to 2-4 with sodium carbonate.

[0038] When using the film-forming agent described in this embodiment, first clean the aluminum workpiece with an acidic or neutral cleaning agent to remove oil and dust on the surface of the aluminum, then clean other substances remaining on the surface of the aluminum with water, and then use this The film-forming agent described in the embodiment is treated at room temperature for 2 to 5 minutes to form a conversion film on the surface of the aluminum material, and finally the surfac...

Embodiment 3

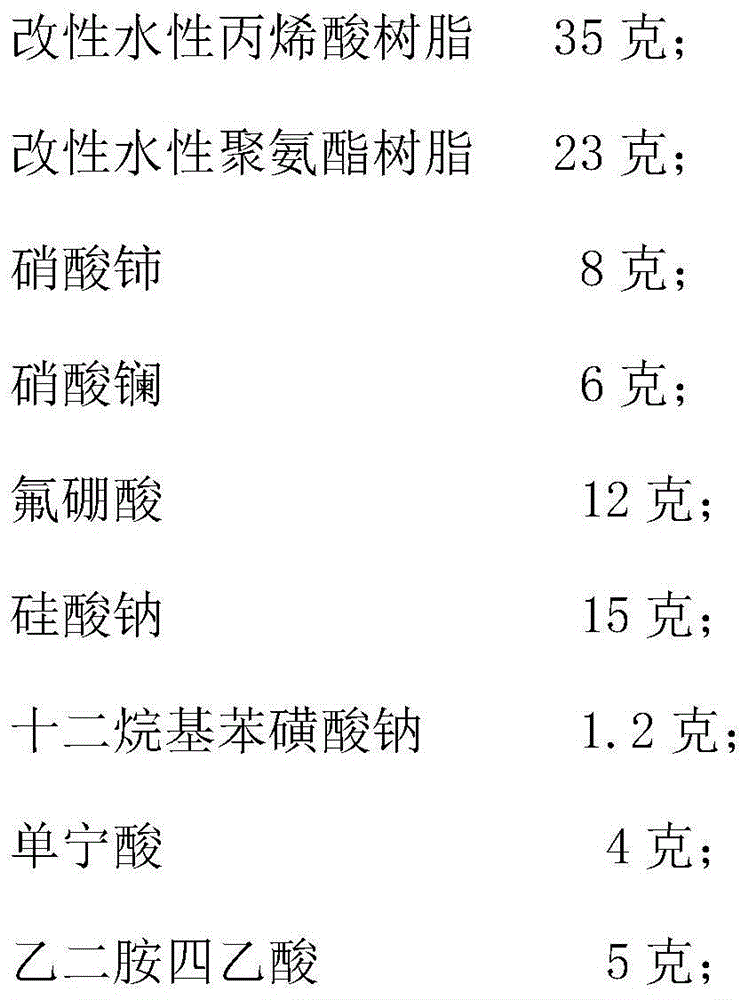

[0040] A new type of aluminum and aluminum alloy polymer chromium-free film-forming agent, which takes the following weight composition and components:

[0041]

[0042]

[0043] Add 800 ml of water, stir well to dissolve and mix evenly, add appropriate amount of water and mix evenly to prepare 1 liter of film-forming agent.

[0044] Dilute the above-mentioned film-forming agent with water, prepare the film-forming agent to water volume ratio of 1:15, and adjust the pH to 2-4 with acetic acid or nitric acid.

[0045] When using the film-forming agent described in this embodiment, first clean the aluminum workpiece with an acidic or neutral cleaning agent to remove oil and dust on the surface of the aluminum, then clean other substances remaining on the surface of the aluminum with water, and then use this The film-forming agent described in the embodiment is treated at room temperature for 2 to 5 minutes to form a conversion film on the surface of the aluminum material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com