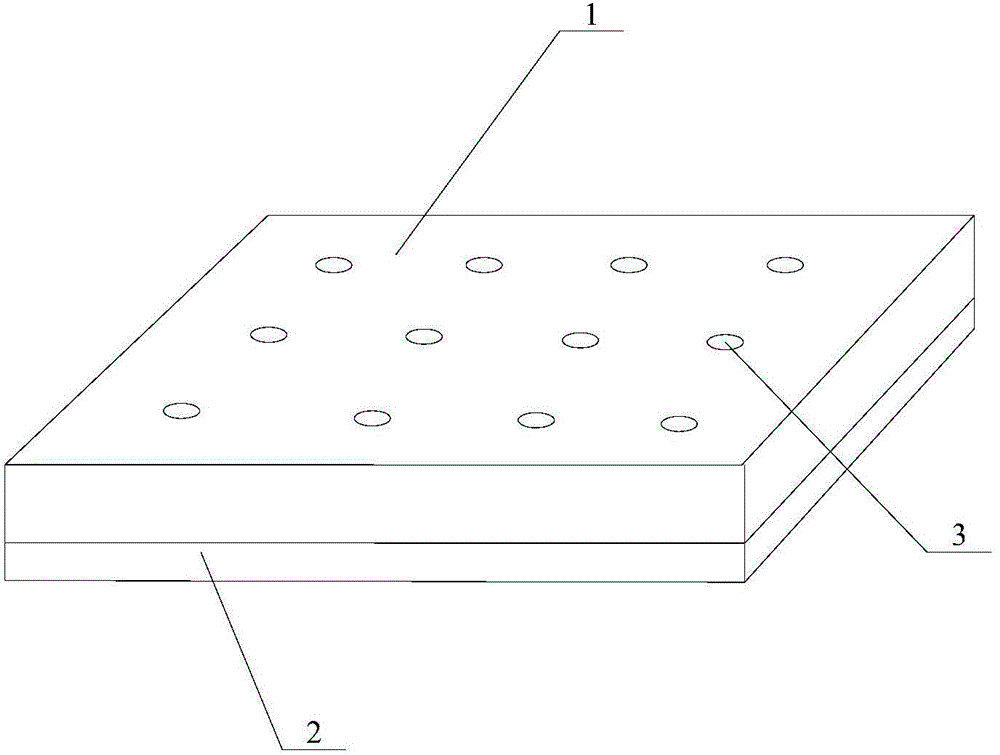

Heat preservation decoration plate and manufacturing method thereof

A thermal insulation decorative board and a technology for its production method, which are applied to chemical instruments and methods, manufacturing tools, lamination devices, etc., can solve the problems of poor thermal insulation effect, complicated manufacturing process, and low fireproof grade of thermal insulation materials, and achieve enhanced thermal insulation effect, The production process is simple and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The insulation layer uses the following raw materials in parts by weight: sepiolite powder 40, perlite powder 15, glass powder 30, bentonite 10, calcium carbonate 2, charcoal 1, sodium phosphate 2, silicon carbide 3, borax 2.1, water 35.

[0044] The decorative layer uses the following raw materials in parts by weight: sepiolite powder 35, glass powder 40, stone powder 10, bentonite 10, potassium feldspar 15, sodium phosphate 3, silicon carbide 2, borax 3, inorganic pigment 1, water 35.

Embodiment 2

[0046] The insulation layer uses the following raw materials in parts by weight: sepiolite powder 50, perlite powder 10, glass powder 40, bentonite 5, calcium carbonate 3, charcoal 0.1, sodium phosphate 3, silicon carbide 2, borax 2, water 25.

[0047] The decorative layer uses the following raw materials in parts by weight: sepiolite powder 44, glass powder 32, stone powder 13, bentonite 5, potassium feldspar 25, sodium phosphate 2, silicon carbide 3, borax 2, inorganic pigment 3, water 25.

Embodiment 3

[0049] The insulation layer uses the following raw materials in parts by weight: sepiolite powder 45, perlite powder 12, glass powder 35, bentonite 7.5, calcium carbonate 2.5, charcoal 0.5, sodium phosphate 2.1, silicon carbide 2.5, borax 3, water 30.

[0050] The decorative layer uses the following raw materials in parts by weight: sepiolite powder 40, glass powder 35, stone powder 12, bentonite 8, potassium feldspar 20, sodium phosphate 2.5, silicon carbide 2.5, borax 2.5, inorganic pigment 1.5, water 30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com