A kind of dendritic polymer and preparation method and its application as catalyst in photocatalytic hydrogen production

A kind of polymer and dendritic technology, applied in the field of energy science and catalysis science, to achieve the effect of increasing light energy utilization, simple process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

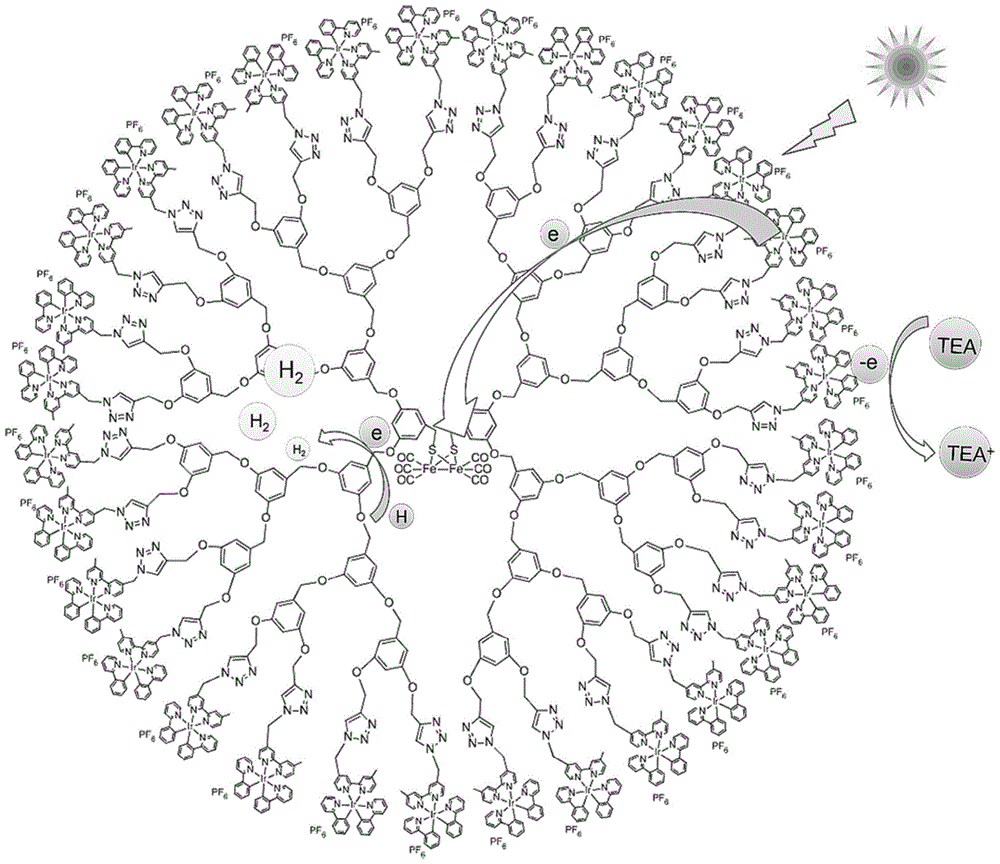

[0045] Preparation of Dendrimer Modified Hydrogenase G4-Hy

[0046]

[0047] Add 1.0 mmol of [(μ-S 2 )Fe(CO) 6 ] and 10.0 mL of dry tetrahydrofuran, liquid nitrogen freezing-vacuumizing-nitrogen, repeat three times. Slowly drop 2.0mL containing 2.2mmolLiBHEt under nitrogen protection and -78℃ cooling bath 3of THF solution. After the dropwise addition, keep stirring at -78°C for 0.5h. 2.1 mmol of benzyl bromide-core aryl ether dendrimers (G4-Br) were dissolved in 2.0 mL of dry tetrahydrofuran solution, and added to the above reaction solution after purging with nitrogen to remove oxygen. After the addition was completed, it was raised to room temperature, and the stirring reaction was continued for 4h. After the reaction, the solvent was removed under reduced pressure, and the crude product was separated by column chromatography (dichloromethane as the eluent) to obtain a dark red solid with a yield of 43%. IR(KBr)ν(cm -1 ):3282,2929,2069(CO),2032(CO),1991(CO),1595,14...

Embodiment 2

[0049] Preparation of Dendrimer Catalyst G4-32Ir-Hy

[0050]

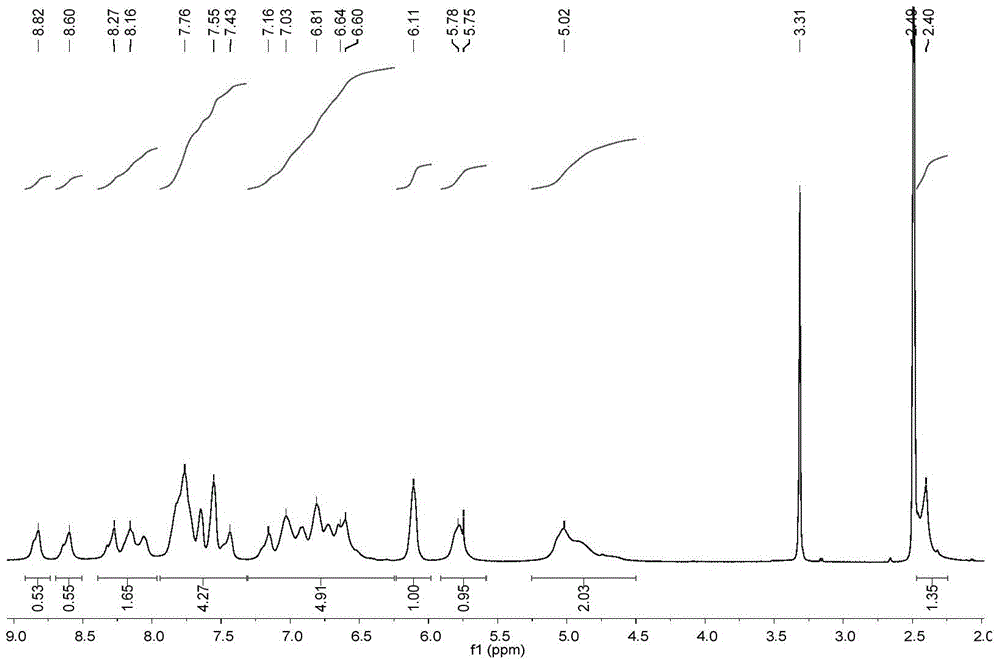

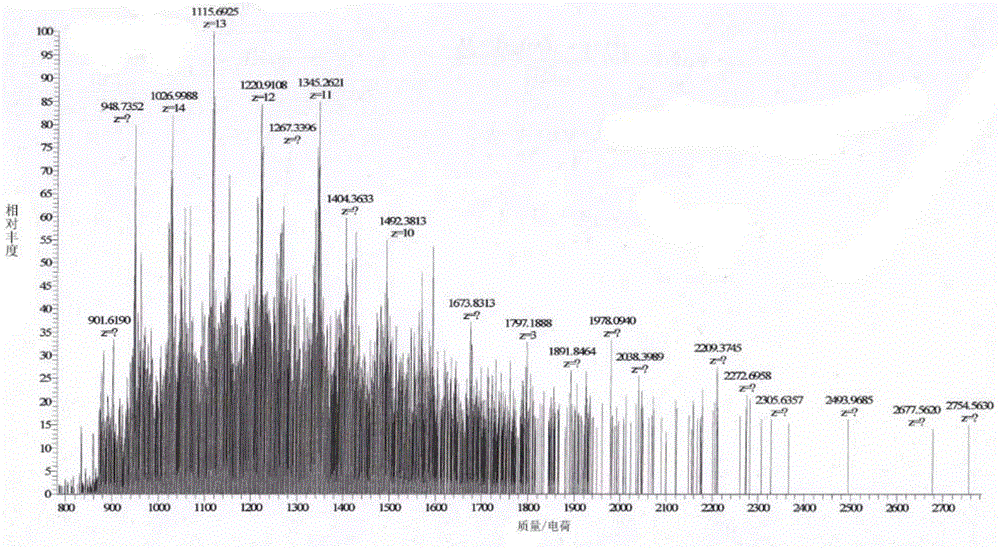

[0051] 1.0mmol of compound G4-Hy, 35.2mmol of compound Ir(N 3 -bpy)(ppy) 2 PF 6 , 0.2mmol of copper sulfate pentahydrate and 0.4mmol of sodium ascorbate were dissolved in tetrahydrofuran / water (volume ratio 4 / 1), and stirred for 48 hours at room temperature under nitrogen protection and light-proof conditions; the mixed solution was decompressed to remove the solvent, and the remaining The solid was dispersed in a mixture of water and dichloromethane, the organic layer was washed with saturated brine, dried, and the solvent was removed under reduced pressure, and the crude product was separated by column chromatography (the eluent was dichloromethane / dichloromethane with a volume ratio of 10 / 1 tetrahydrofuran) to obtain brown-yellow solid G4-32Ir-Hy with a yield of 25%. The H NMR spectrum and mass spectrum of compound G4-32Ir-Hy are as follows figure 1 and figure 2 shown. Infrared, NMR and mass spectromet...

Embodiment 3

[0055] In Example 3, two groups of experiments I and II were conducted simultaneously, and solvents with different concentrations were configured for photocatalytic hydrogen production.

[0056] Configure two 10mL mixed solvents of I and II respectively, V 乙腈 :V 水 = 9 / 1 and V 丙酮 :V 水 =9 / 1, 0.4M triethylamine (TEA) was added thereto to adjust the pH to 10. After 10 hours of light irradiation, the amount of photocatalytic hydrogen production is shown in Table 1:

[0057] Table 1

[0058] Hydrogen volume / microliter Solvent ratio I 439 V 乙腈 :V 水 =9 / 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com