A kind of method for preparing ceria nanocrystalline film

A technology of cerium dioxide and nanocrystals, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of long sol preparation cycle, easy cracking of film, shrinkage and cracking of film, etc., to solve the problem of long preparation cycle, Quality control, surface leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

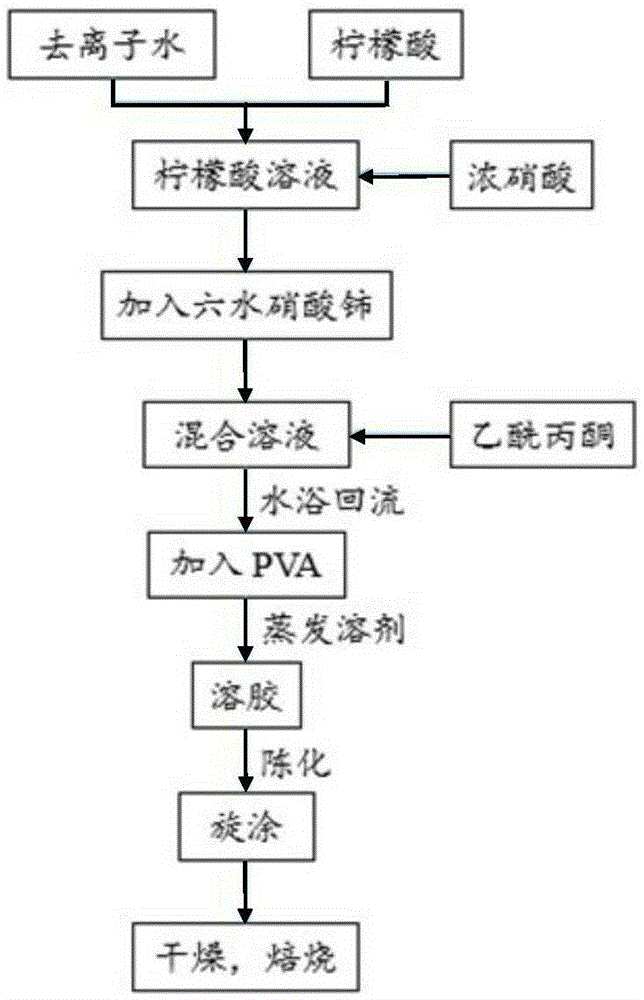

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh 2.105 g of polyvinyl alcohol and add 40 ml of deionized water, heat and stir in a water bath at 95° C. for 2 h to obtain PVA with a mass fraction of 5%. Silicon wafers were ultrasonically cleaned with dilute nitric acid, acetone, and deionized water for 30 min, and then used as substrates after air drying.

[0036] (2) Weigh 3.151g of citric acid and dissolve it in 5ml of deionized water.

[0037] (3) Add about 3ml of concentrated nitric acid with a purity of 65-68% into the citric acid solution, and stir to make the solution pH<1.

[0038] (4) Weigh 2.173g of cerium nitrate hexahydrate and slowly dissolve it into the solution of step 3 and stir until completely dissolved.

[0039] (5) Measure 2-3ml of acetylacetone and add it to the solution obtained in step 4. After stirring, seal the beaker where the solution is placed to prevent the dispersant from volatilizing. Then put it in a water bath at 65°C and heat for about 6 hours.

[0040] (6) Open the beaker,...

Embodiment 2

[0044] (1) Weigh 4.21g of polyvinyl alcohol and dissolve it in 40ml of deionized water, stir in a water bath at 95°C for 3h to obtain 10wt.% PVA, ultrasonically clean the silicon wafer with dilute nitric acid, alcohol, acetone, and deionized water for 30min, and leave it at room temperature dry.

[0045] (2) Weigh 4.201 g of citric acid, add 5 ml of deionized water and stir until completely dissolved.

[0046] (3) Add about 4ml of concentrated nitric acid with a purity of 65-68% into the above solution, stir to make the solution pH<1.

[0047] (4) Weigh 2.173g of cerium nitrate hexahydrate and dissolve slowly into the solution of step 3, and stir until completely dissolved.

[0048] (5) Measure about 3ml of acetylacetone, add the solution obtained in step 4, seal the beaker where the solution is placed after stirring, and then put it into a water bath at 75°C and heat for about 5 hours.

[0049] (6) Open the beaker, when the solution changes from reddish brown to light yello...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com