Molecularly imprinted porous magnetic cellulose microspheres on the surface of artesunate and its preparation method and application

A technology of surface molecular imprinting and porous cellulose, which is applied in the direction of microsphere preparation, microcapsule preparation, chemical instruments and methods, etc., can solve the problems of inability to complete integration, small adsorption amount, complicated steps, etc., and achieve magnetic response characteristics retention , increased adsorption capacity, uniform and stable magnetic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

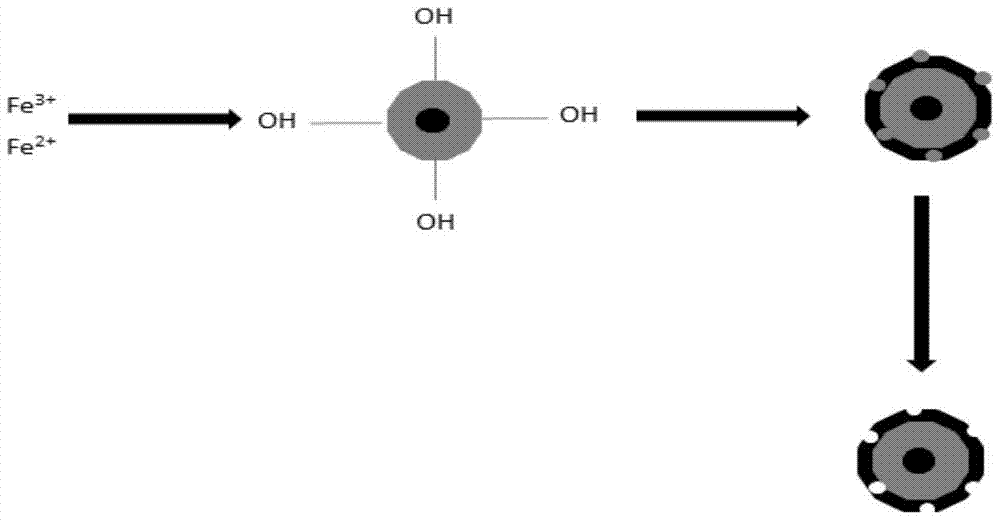

[0054] (1) Fe 3 o 4 Preparation of nanoparticles:

[0055] Iron Sulfate (Fe 2 (SO 4 ) 3 ) and ferrous sulfate (FeSO 4 ) was dissolved in deionized water except peroxygen, and 0.125mol / LFe 2 (SO 4 ) 3 solution and 0.1mol / L FeSO 4 The solutions were mixed at a volume ratio of 1.25:1, and sonicated for 0.5 h at 25° C. under nitrogen protection. Slowly add concentrated sodium hydroxide solution (0.5-1 mol / L) dropwise into the solution, adjust the pH of the mixed solution to 10-12, and continue to sonicate for 0.5 h. Raise the temperature to 60°C, and sonicate for 1 h under nitrogen protection. will generate Fe 3 o 4 Stand still, use magnet to separate and recover, wash 3 times alternately with acetone and water, get Fe 3 o 4 Nanoparticles.

[0056] (2) Preparation of magnetic cellulose solution:

[0057] Freeze the alkali / urea aqueous solution to -15-0°C, then add cellulose, stir vigorously to dissolve the cellulose, and remove impurities by centrifuging to obtain ...

Embodiment 1

[0063] Example 1 Preparation of Molecularly Imprinted Porous Cellulose Microspheres on the Surface of Artesunate

[0064] (1) Fe 3 o 4 Preparation of nanoparticles:

[0065] After 100ml of distilled water at room temperature is ultrasonicated at 40kHz for 5-10min, add 0.0125mol of Fe 2 (SO 4 ) 3 powder and 0.01mol FeSO 4Powder, prepare 0.125mol / L Fe 2 (SO 4 ) 3 solution and 0.1mol / L FeSO 4 solution, according to Fe 2 (SO 4 ) 3 : FeSO 4 Mixed at a molar ratio of 1.25:1. Continue to sonicate at 25°C under nitrogen protection to obtain a uniformly mixed solution. , slowly drop NaOH solution with a concentration of 1.0 mol / L to adjust the pH value of the solution to 12, and continue to sonicate for 0.5 h. Raise the temperature to 60°C, and sonicate for 1 h under nitrogen protection. Wherein, the ultrasonic power is 40kHz. will generate Fe 3 o 4 Stand still, use magnet to separate and recover, wash 3 times alternately with acetone and water, get Fe 3 o 4 Nanopa...

Embodiment 2

[0074] Example 2 Determination of the Adsorption Performance of Molecularly Imprinted Porous Cellulose Microspheres on the Surface of Artesunate

[0075] Draw the standard curve of artesunate by ultraviolet-visible spectrophotometer: use DMSO solution as solvent, and the preparation concentration is 10 -4 -10 -5 mol / L(10 -5 , 2x10 -5 , 3x10 -5 , 4x10 -5 , 5x10 -5 , 6x10 -5 , 7x10 -5 , 8x10 -5 , 9x10 -5 , 10 -4 ) gradient concentration of artesunate solution, the UV maximum absorbance value corresponding to the peak value is 238nm, draw the artesunate concentration and the corresponding absorbance value at 238nm, and obtain a linear regression equation: Y=0.20209X R 2 =0.996, where X represents the concentration of artesunate, and Y represents the corresponding absorbance value at the maximum UV peak at 238nm. The linear relationship between artesunate absorbance intensity and concentration, such as Figure 7 shown.

[0076] The method for measuring the molecularly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com