Thermosetting polymer compound, thin film and preparation method thereof

A composite film and thermosetting technology, applied in the field of thermosetting polymer composite film and its preparation, can solve the problems of non-recycling, inability to melt and plasticize, environmental pollution, etc., and achieve the effect of avoiding complex product structure and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

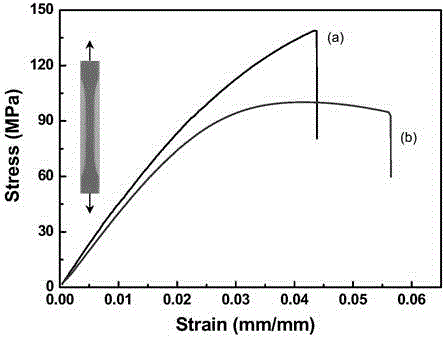

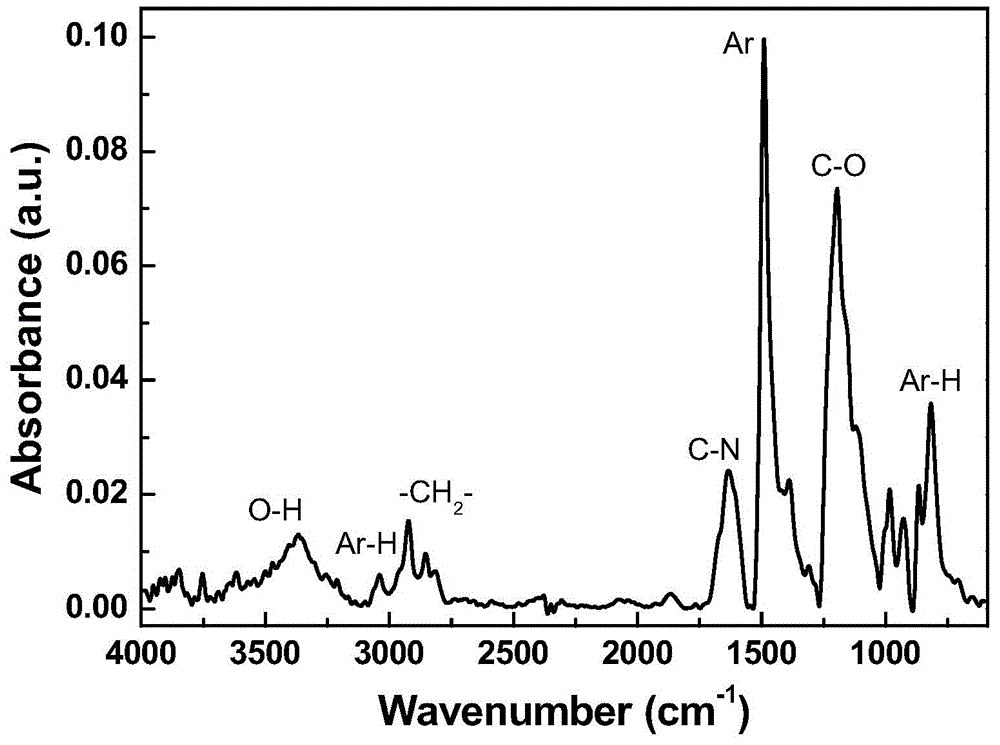

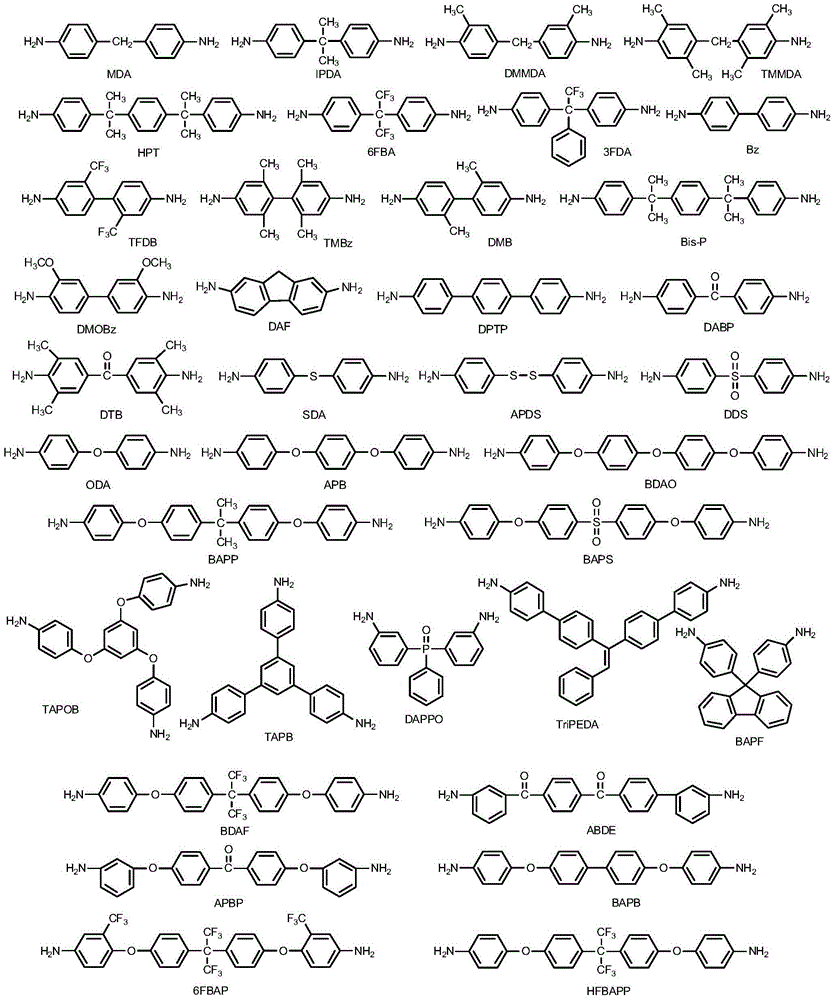

[0030] Graphene oxide was modified with aromatic diamine MDA (the product is labeled as MDA-GO, the primary amino group content is 0.31mmol / g), and a 2mg / ml MDA-GO aqueous solution was prepared. 20.01 mmol of paraformaldehyde and 10 ml of dimethylformamide / water mixed solvent were prepared into a suspension, stirred and reacted at 100° C. for 0.1 hour for depolymerization, and cooled to room temperature to obtain a colorless and transparent formaldehyde reaction liquid. Dissolve 10 mmol of aromatic diamine MDA in 8 ml of dimethylformamide to obtain a transparent aromatic amine reaction solution. Mix the formaldehyde, aromatic amine reaction solution and 2ml MDA-GO aqueous solution evenly (the volume content of water in the mixed solvent of the final reaction system is 10%), ultrasonically disperse at room temperature for 10 minutes, and stir and react at 30°C for 60 minutes for prepolymerization. Lay a film on a horizontal glass plate, dry at 120°C for 0.5 hours, and dry at 18...

Embodiment 2

[0032] Graphene oxide was modified with aromatic diamine SDA (the product is labeled as SDA-GO, the primary amino group content is 0.63mmol / g), and a 20mg / ml SDA-GO aqueous solution was prepared. 14.13 mmol of paraformaldehyde and 7 ml of 2,5-dimethylfuran / water mixed solvent were prepared into a suspension, stirred and reacted at 80°C for 0.8 hours for depolymerization, and cooled to room temperature to obtain a formaldehyde reaction liquid. Dissolve 7 mmol of aromatic diamine ODA in 3 ml of 2,5-dimethylfuran to obtain an aromatic amine reaction liquid. Mix the formaldehyde, aromatic amine reaction solution and 10ml SDA-GO aqueous solution evenly (the volume content of water in the mixed solvent of the final reaction system is 50%), ultrasonically disperse at room temperature for 60 minutes, and stir and react at 50°C for 5 minutes for prepolymerization. Lay a film on a horizontal glass plate, dry at 70°C for 5 hours, and dry at 190°C for 3 hours to obtain the target product ...

Embodiment 3

[0034]Graphene oxide was modified with aromatic diamine APB (the product is marked as APB-GO, the primary amino group content is 0.27 mmol / g), and a 3 mg / ml APB-GO aqueous solution was prepared. 16.01 mmol of paraformaldehyde and 6 ml of dimethyl sulfoxide / water mixed solvent were prepared into a suspension, stirred and reacted at 60° C. for 2 hours for depolymerization, and cooled to room temperature to obtain a formaldehyde reaction liquid. Dissolve 8 mmol of aromatic diamine BDAO in 2 ml of N-methylpyrrolidone to obtain an aromatic amine reaction liquid. Formaldehyde, aromatic amine reaction solution and 12ml APB-GO aqueous solution were mixed evenly (the volume content of water in the mixed solvent of the final reaction system was 60%), ultrasonically dispersed at room temperature for 30 minutes, stirred and reacted at 40°C for 3 minutes for prepolymerization, and further Lay film on a horizontal glass plate, dry at 80°C for 3 hours, and dry at 200°C for 2 hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com