Low-temperature polymer conductive paste and preparation method thereof

A technology of conductive paste and polymer, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problems of poor adhesion between resin and substrate, electrode resistivity, conductive film contact resistance, Adhesion effects and other issues, to achieve the effect of low surface energy, excellent dispersion function, excellent bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

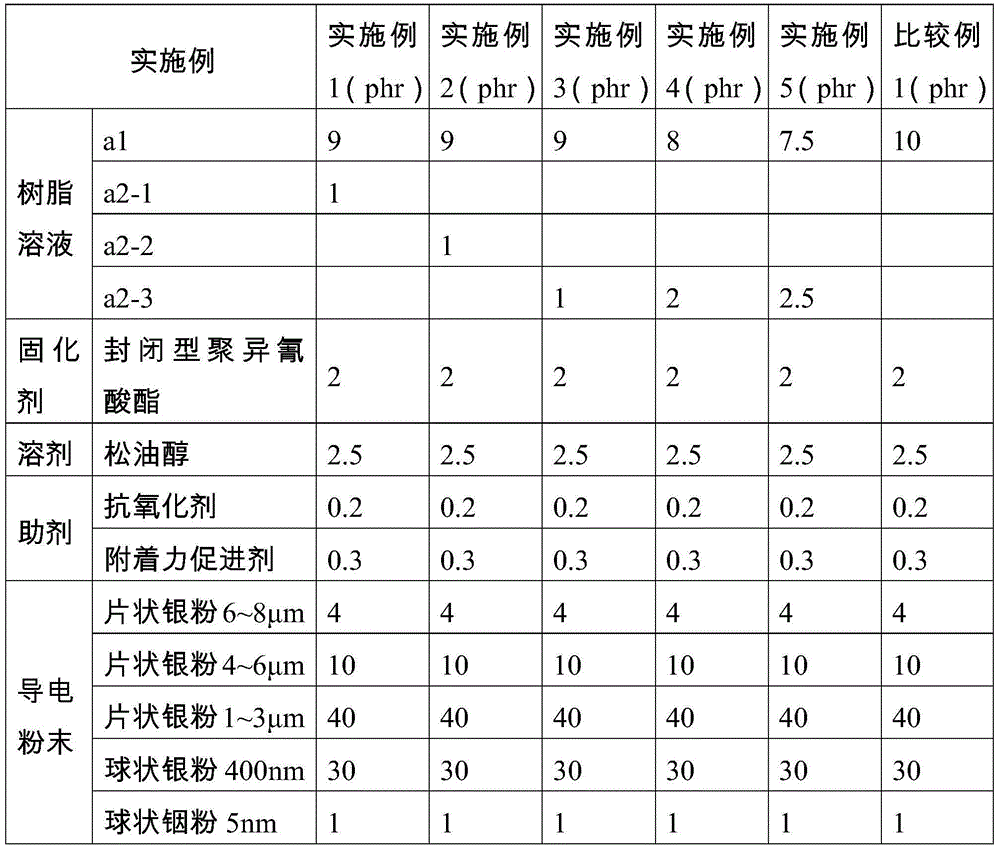

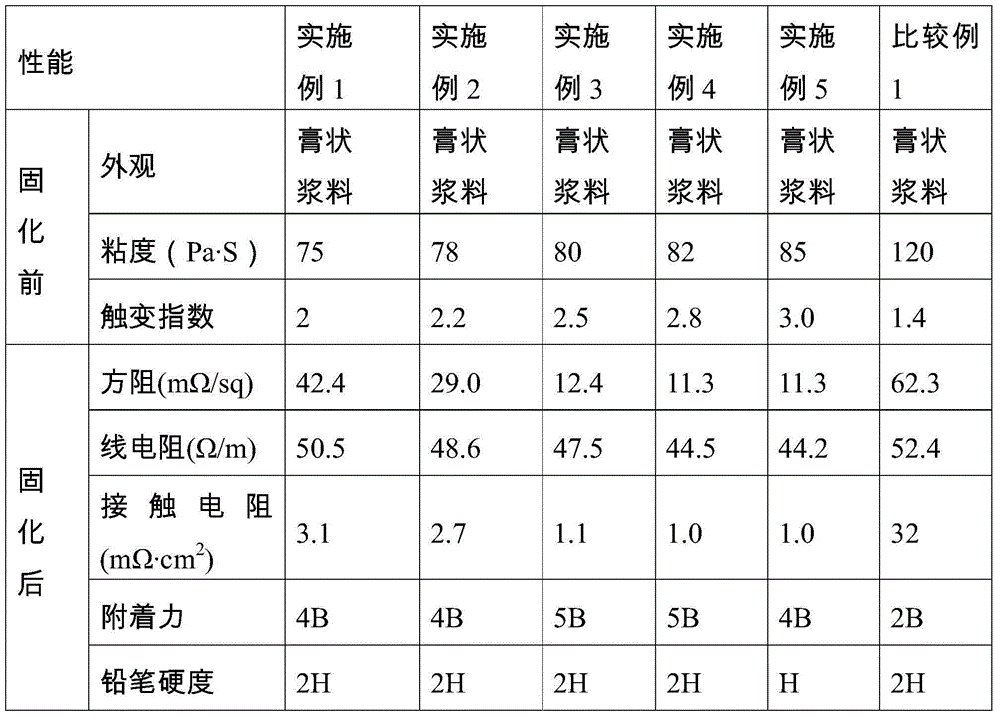

[0033] The preparation process of the low-temperature polymer conductive paste of the present invention mainly includes four steps:

[0034] (1) Dissolution of resin: add functional resin a to a glass reactor, then add a certain proportion of organic solvent b, and then dissolve functional resin a into organic solvent b by heating and mechanical stirring to prepare a resin solution for later use.

[0035] (2) Pre-dispersion of conductive paste: Add a certain proportion of dissolved resin solution, conductive filler, organic solvent, curing cross-linking agent and functional additives to the glass reactor, and pre-disperse the paste through a planetary mixer. Prepare the pre-dispersed slurry for later use.

[0036] (3) Grinding and dispersing of the conductive paste: Grinding and dispersing the pre-dispersed slurry with a three-roll mill to prepare a uniformly ground conductive paste for use.

[0037] (4) Vacuum defoaming of the conductive paste: the ground paste is vacuum-cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com