Preparation method of calcium alginate nanometer microspheres

A technology of nano-microspheres and calcium alginate, which is applied to medical preparations and pharmaceutical formulations with non-active ingredients, can solve the problems of organic solvent residues, toxicity hazards and other problems that are difficult to avoid in the treatment process, and achieves little difference between batches and no Organic solvent, effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

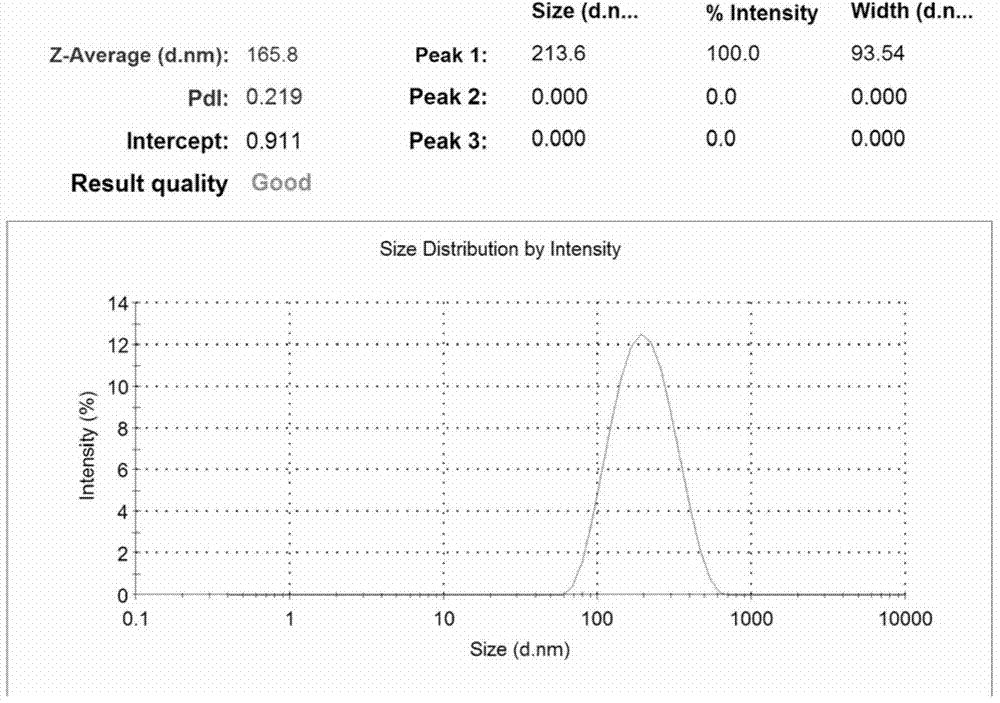

[0027] Weigh 0.3g of sodium alginate and place it in 25g of water to swell for 8 hours, stir and dissolve fully to obtain the aqueous phase mixed solution a; dissolve 15g of soybean lecithin and 15g of absolute ethanol in 45g of isopropyl myristate and mix evenly to obtain the oil phase Mix solution b; mix a and b two phases at room temperature, stir at 10000r / min at high speed for 10 minutes, use a high-pressure homogenizer to homogenize at 50Mpa for 10 minutes to obtain a transparent / translucent W / O submicroemulsion solution, and measure it with a laser particle size analyzer Submicron emulsion particle size distribution (attached figure 1 ), the average particle size is 64.29nm, and the polydispersity index PDI is 0.099. Weigh 0.15gCaCl 2 Dissolve in 10mL water to prepare solidified solution; take 10mL submicron emulsion solution, add solidified solution drop by drop into submicron emulsion solution under 1000r / min magnetic stirring state, solidify for 20min and leave to s...

Embodiment 2

[0029] Weigh 0.05g of sodium alginate and place it in 10g of water to swell for 6 hours, stir and dissolve fully to obtain the aqueous phase mixed solution a; dissolve 18g of polyethylene glycol caprylic glycerin and 18g of PEG-400 in 54g of ethyl oleate Mix evenly to obtain oil phase mixed solution b; mix a and b at room temperature, stir at 10000r / min at high speed for 10min, and homogenize with a high-pressure homogenizer at 50Mpa for 20min to obtain a transparent / translucent W / O submicroemulsion solution, laser particle size The particle size distribution of submicron emulsion was determined by instrument. Weigh 0.1gCaCl 2 Dissolve in 10mL of water to prepare the solidified solution; take 10mL of the submicron emulsion solution, add the solidified solution dropwise to the submicron emulsion solution under 1000r / min magnetic stirring state, solidify for 10min and let it stand for stratification, then discard the upper oil phase to obtain seaweed Calcium Oxide Nanospheres. ...

Embodiment 3

[0031] Weigh 0.32g of sodium alginate and place it in 16g of water to swell for 6 hours, stir to dissolve fully to obtain the aqueous phase mixed solution a; Oil phase mixed solution b; mix the two phases a and b at room temperature, stir at 10000r / min at high speed for 10 minutes, and use a high-pressure homogenizer at 60Mpa to homogenize for 15 minutes to obtain a transparent / translucent W / O submicroemulsion solution. Microemulsion particle size distribution and average particle size. Weigh 0.3gCaCl 2 Dissolve in 10mL water to prepare solidified solution; take 10mL submicron emulsion solution, add solidified solution drop by drop into submicron emulsion solution under 1000r / min magnetic stirring state, solidify for 20min and leave to separate layers, then discard the upper oil phase to obtain seaweed Calcium Oxide Nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com