Icaritin preparation method

A technology of icariin and epimedium extract, which is applied in the field of medicine, can solve the problems of low conversion rate of enzymatic hydrolysis and many impurities in the final product, and achieve the effects of improving purity, easy purification, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

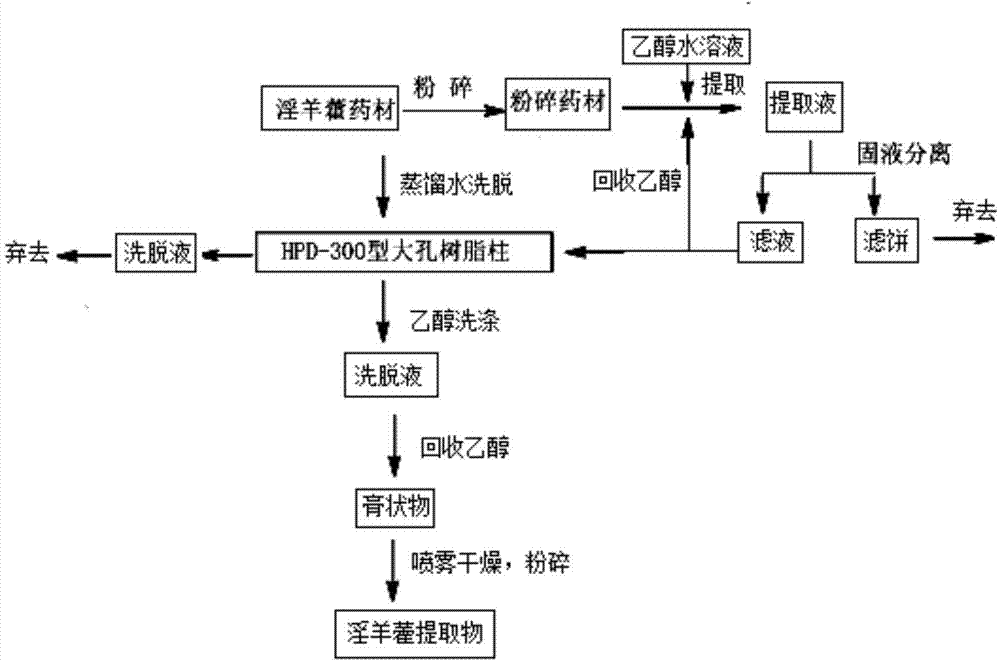

[0038] 1. Preparation of Epimedium Extract

[0039] 1.1 Extraction

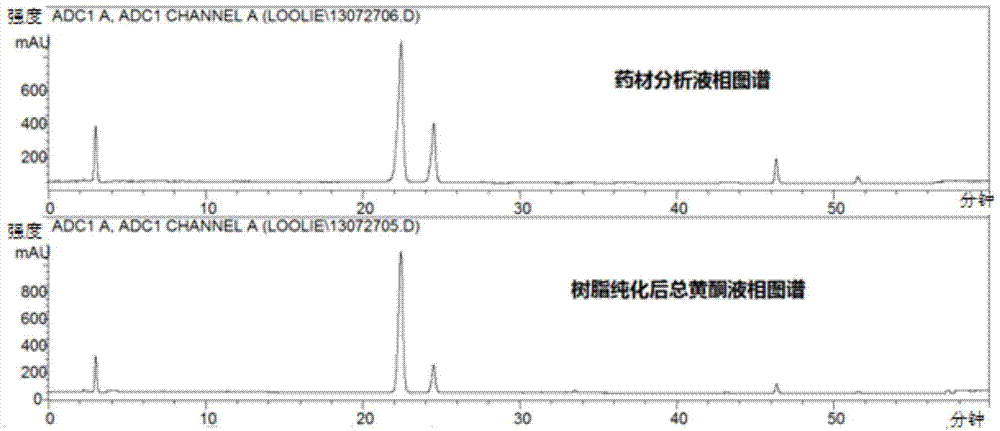

[0040] The present embodiment extracts in stages except the stem, and Epimedium leaves total 490Kg, crush it, and use 14 times, 10 times of amount (v / w) 40% ethanol aqueous solution reflux extraction of 40% volume concentration respectively, 2 times each time Hour. Recover ethanol until the extract has no alcohol smell, and detect the total flavonoids in the extract by high performance liquid chromatography, see attached figure 1 upper half of the picture;

[0041] 1.2 Macroporous resin purification

[0042] Concentrate the ethanol extract obtained in step 1.1 to remove ethanol, and then purify it with a macroporous resin. First, the macroporous resin column was eluted with distilled water having 8 times the volume of the macroporous resin column bed, and the flow rate of distilled water elution was 1 times the column volume / hour. After the elution was completed, the eluent was discarded;

[0043] Wash...

Embodiment 2

[0056] 1. Preparation of icariin by enzymatic hydrolysis

[0057] Weigh 10Kg of the commercially available Epimedium extract, add it into 100L pH=5.5 disodium hydrogen phosphate-citric acid buffer solution, and dissolve it at a stirring speed of 100rpm. When the temperature of the system was kept constant at 57°C, 1.5Kg of β-glucosidase was added to stir the reaction. After 16 hours of constant temperature reaction, the stirring was stopped, and the temperature of the reaction liquid was lowered to 25°C.

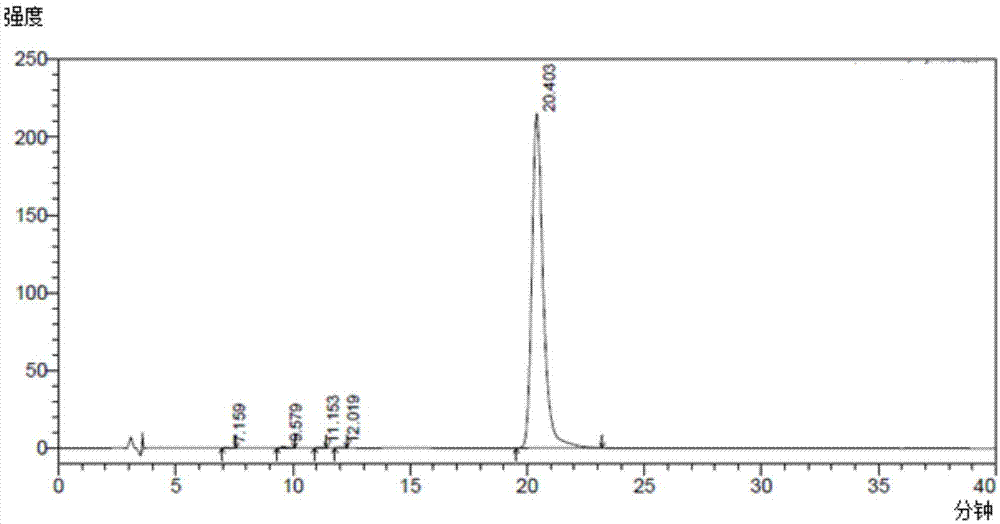

[0058] 2. Purification of Icaritin

[0059] After the enzymolysis reaction, the reaction solution was centrifuged, and the filter cake was collected. After drying, the weight was 7.85Kg. After pulverization, 88.11Kg of acetone was added, stirred for 1 hour, filtered, and 64.55Kg of purified water was added to the acetone solution, then heated to 63°C The system solvent was refluxed until the solution was clear. After the solution was slowly cooled to room temperature,...

Embodiment 3

[0061] 1. Preparation of icariin by enzymatic hydrolysis

[0062] Weigh 8.7Kg of the commercially available Epimedium extract, add it into 174L pH=4.8 citric acid-sodium citrate buffer solution, and dissolve it at a stirring speed of 100rpm. When the temperature of the system is kept constant at 45°C, add 0.435Kg of β-glucosidase and stir the reaction. After 20 hours of constant temperature reaction, the stirring was stopped, and the temperature of the reaction liquid was lowered to 30°C.

[0063] 2. Purification of Icaritin

[0064] After the enzymolysis reaction, the reaction solution was centrifuged, and the filter cake was collected. After drying, the weight was 6.55Kg. After crushing, 76.34Kg of acetone was added, stirred for 1 hour, filtered, and 55.93Kg of purified water was added to the acetone solution, and the temperature was raised to 62°C to make the system The solvent was refluxed until the solution was clear. The temperature of the solution was slowly lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com