Method for removing heavy metal cadmium and lead pollutants in water by sodium alginate/gelatin coated nano zero-valent iron

A technology of nano-zero-valent iron and sodium alginate, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as loose structure, easy leakage, and fragility, and achieve recycling, The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

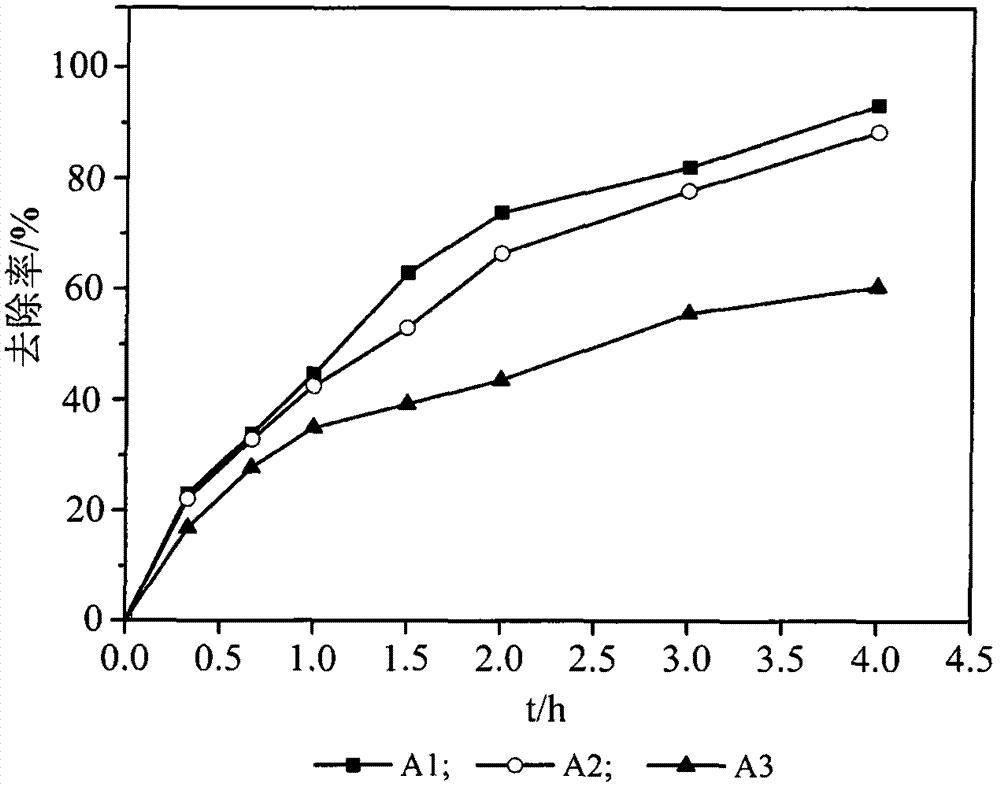

[0040] Embodiment 1: adjustment coating raw material SA, Gel concentration are respectively 1.5%, 0.5%, 1.5%, 1.0%, 2.0%, 1.5%, to freshly prepared 30mg nanometer Fe 0 Coated and added to 200mL of 100mg·L deoxidized -1 In the Cd(II) reactor, the reaction was carried out at room temperature (25°C) under 250rpm shaking conditions. The pH was not adjusted during the reaction. The quantitative reaction solution was taken at regular intervals and filtered through a 0.45μm membrane. The NovAA400 atomic absorption spectrometer was used to analyze The remaining Cd(II) concentration in the solution was detected and its removal rate was calculated. The results showed that when the concentrations of coating materials SA and Gel were 1.5% and 0.5%, respectively, the removal rate of Cd(II) was relatively highest, and the removal rate could reach 97.9% after shaking reaction for 24 hours.

Embodiment 2

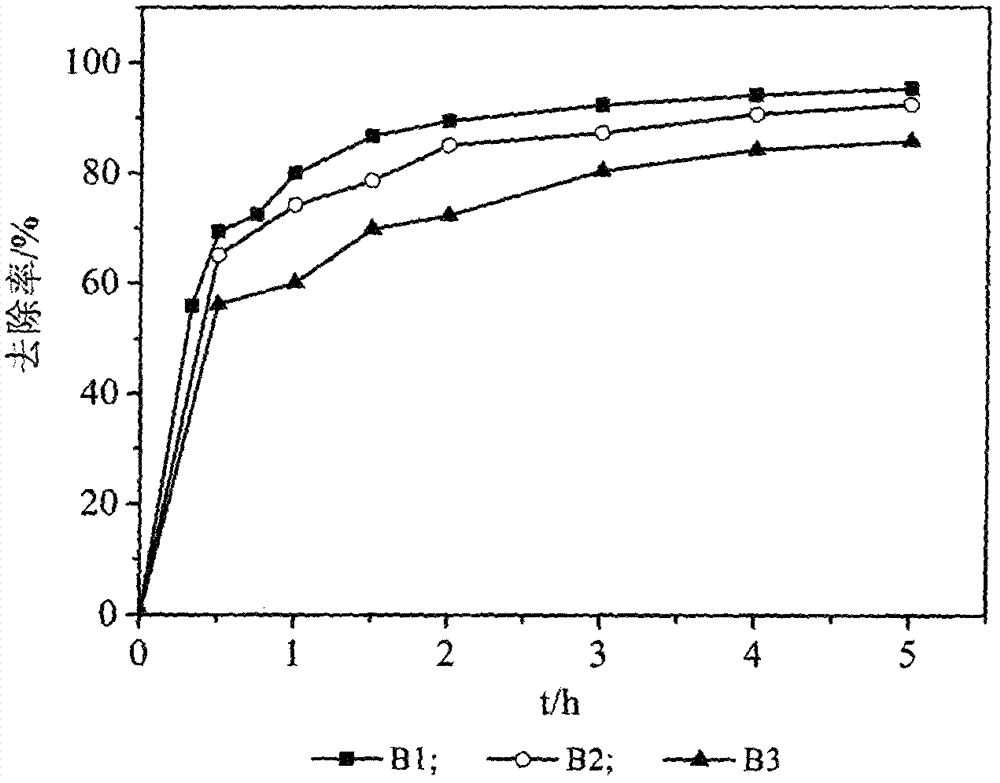

[0041] Embodiment 2: adjustment coating raw material SA, Gel concentration are respectively 1.5%, 0.5%, 1.5%, 1.0%, 2.0%, 1.5%, to freshly prepared 70mg nanometer Fe 0 Coated and added to 200mL of 500mg·L deoxygenated -1 In the Pb(II) reactor, the reaction was carried out at room temperature (25°C) under 250rpm shaking conditions. The pH was not adjusted during the reaction. The quantitative reaction solution was taken at regular intervals and filtered through a 0.45μm membrane. The NovAA400 atomic absorption spectrometer was used to analyze The remaining Pb(II) concentration in the solution was detected, and its removal rate was calculated. The results show that the reaction with Cd(II) is the same, when the concentrations of SA and Gel are 1.5% and 0.5% respectively, the coated nano-Fe 0 The reactivity is relatively the highest, and the removal rate of Pb(II) can reach 95.3% after 5 hours of reaction.

Embodiment 3

[0042] Embodiment 3: in 250mL reactor, adding concentration is 200mg / L, 100mg / L, 50mg / L Cd (II) solution 200mL respectively, add 1.5%SA, 30mg nanometer Fe of 0.5%Gel ratio coating successively 0 , to investigate the coated nano-Fe 0 The effect of dosage on the removal effect of Cd(II), and the uncoated nano-Fe 0 Gel spheres removed 100 mg / L Cd(II) for comparative shaking reactions. The experimental results show that the uncoated Fe 0 The gel spheres hardly reacted with Cd(II).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com