An amlodipine besylate composition used for direct tabletting and a preparing method of tablets of the composition

A technology of amlodipine besylate and its composition, which is applied in the field of preparation of amlodipine besylate composition and its tablets, which can solve the problems of large tablet weight differences, poor fluidity of medicinal powder, and splits, and achieve weight differences Improved, complete dissolution, high dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

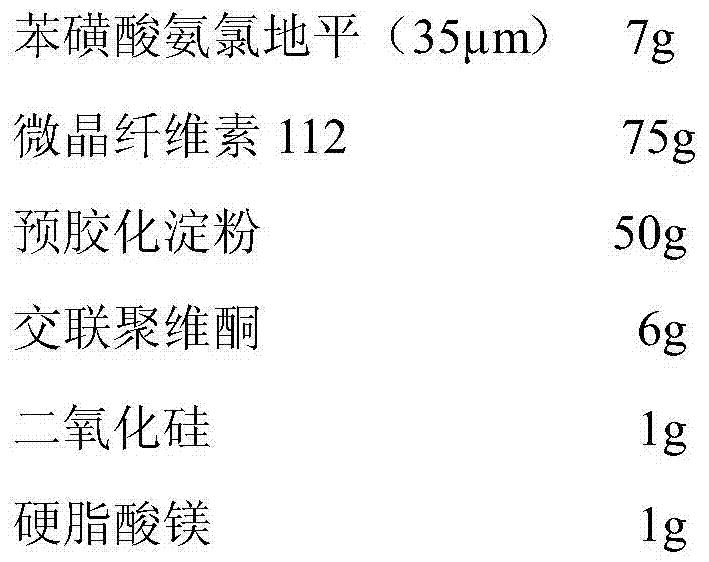

[0018] 1 core prescription

[0019]

[0020] 2 Preparation methods

[0021] Weigh amlodipine besylate, microcrystalline cellulose 112, pregelatinized starch and crospovidone of 2 / 3 of the recipe amount according to the recipe, and mix them evenly. Then add the remaining crospovidone, silicon dioxide and magnesium stearate, mix evenly, press into tablets, and apply film coating to obtain the final product.

Embodiment 2

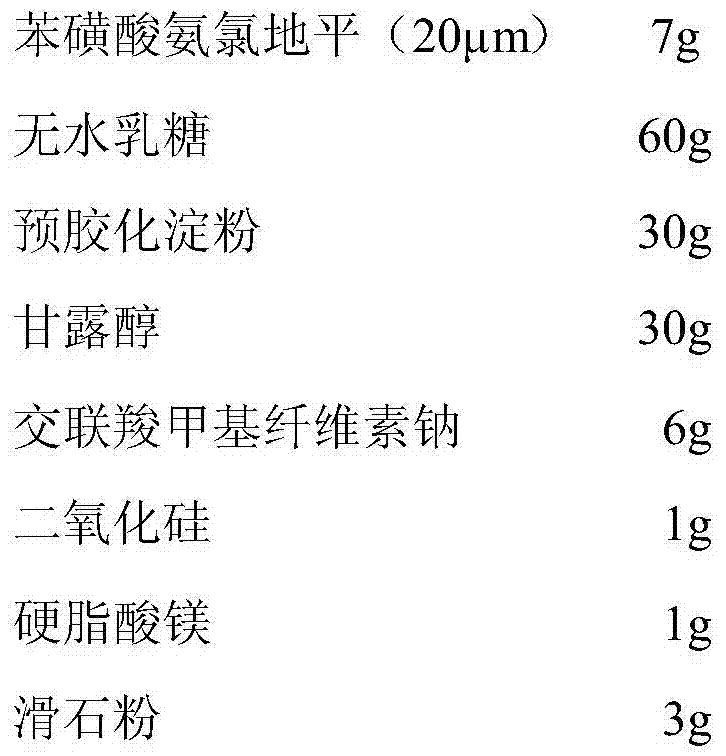

[0023] 1 core prescription

[0024]

[0025] 2 Preparation methods

[0026] Weigh amlodipine besylate, anhydrous lactose, mannitol, pregelatinized starch and 2 / 3 of the recipe amount of croscarmellose sodium according to the recipe, mix well, then add the remaining croscarmellose Sodium cellulose, silicon dioxide, magnesium stearate and talc are mixed uniformly, compressed into tablets, and film-coated to obtain the final product.

Embodiment 3

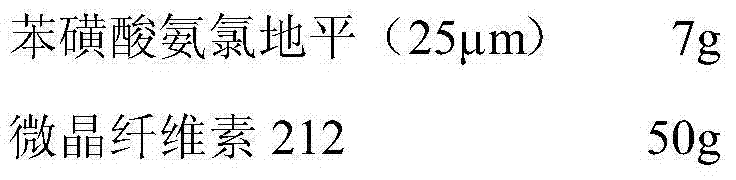

[0028] 1 core prescription

[0029]

[0030]

[0031] 2 Preparation methods

[0032] Weigh amlodipine besylate, microcrystalline cellulose 212, pregelatinized starch, calcium hydrogen phosphate, hypromellose and 2 / 3 of the croscarmellose sodium according to the recipe quantity, mix well , and then add the remaining croscarmellose sodium, silicon dioxide and magnesium stearate, mix evenly, press into tablets, and apply a film coating to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com