Method for preparing crystalline silicon by direct electrolysis in ionic liquid at low temperature

An ionic liquid, crystalline silicon technology, applied in the field of electrolysis, can solve problems such as limited application and high volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

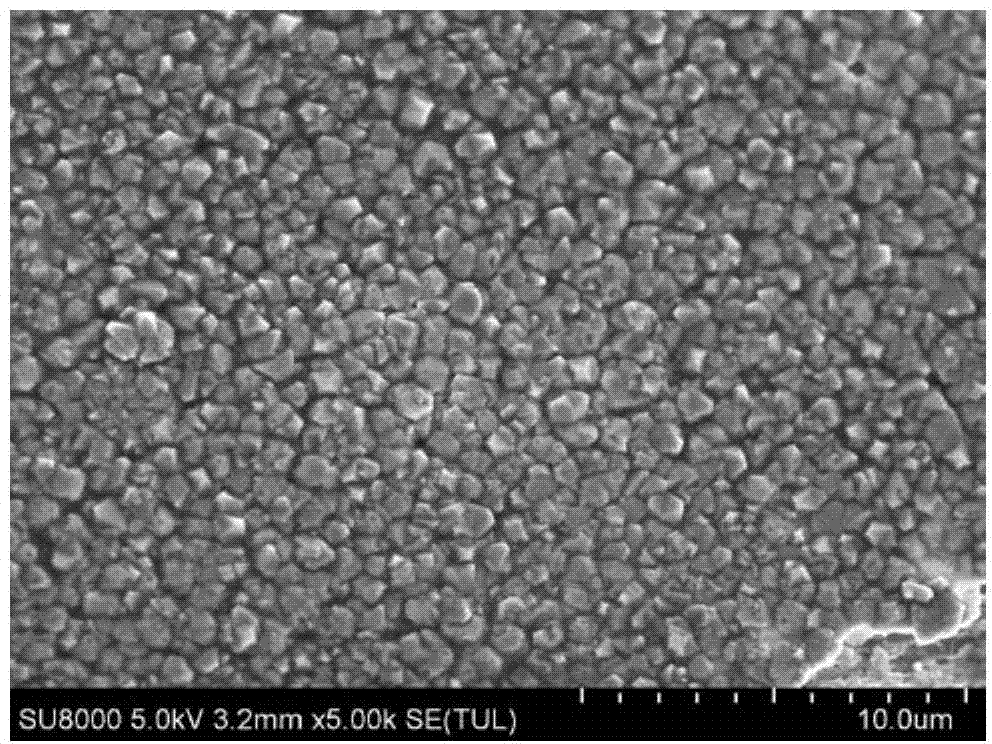

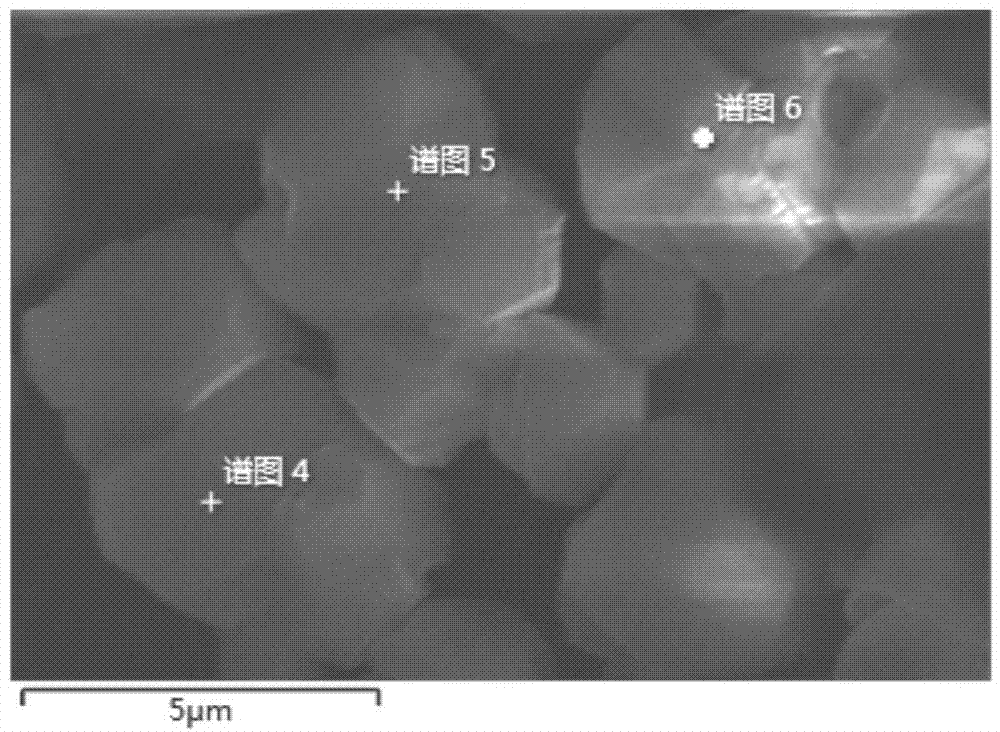

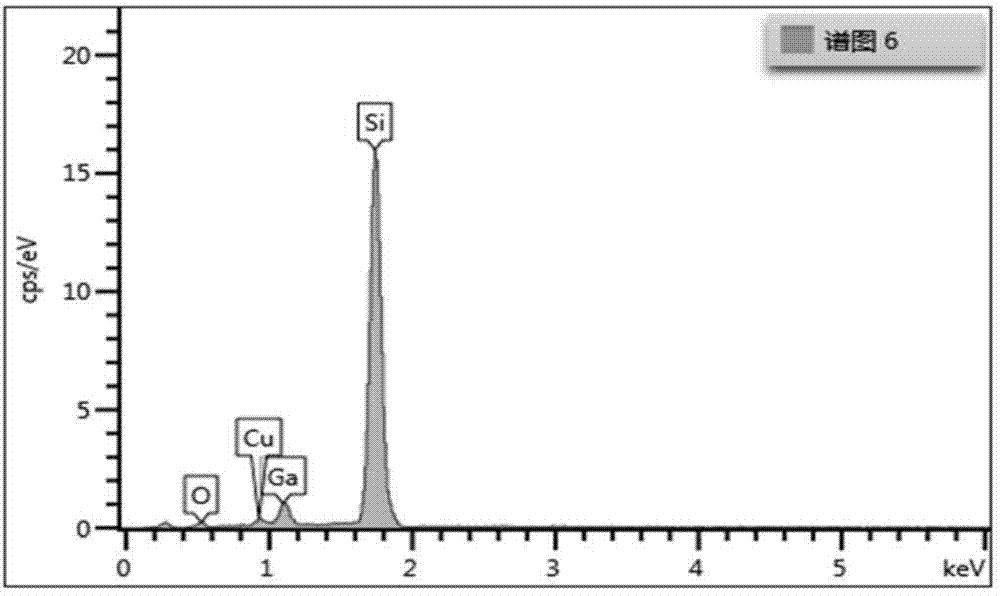

Embodiment 1

[0020] SiCl 4 dissolved in [N 4441 TFSI] in the ionic liquid, the active material concentration is 0.1M, the working electrode is 100% liquid gallium, the auxiliary electrode is a glassy carbon electrode, and the reference electrode is Ag / (10mM AgNO 3 acetonitrile solution). Constant voltage electrodeposition, the working voltage is -1.8V, the temperature is 90°C, after 8 hours of electrodeposition on the liquid electrode to obtain the product silicon, after the product and the liquid electrode are taken out of the electrolyte at the same time, they are washed with DMF for many times to ensure that the ion The liquid is cleaned, and then the crystalline silicon product is enriched into the organic phase with a mixed solution of anhydrous methanol and acetone equal in volume, and the liquid metal electrode is transferred out. A small amount of liquid metal on the surface of the obtained product is removed by boiling in 10% hydrochloric acid solution. Clean the product with wa...

Embodiment 2

[0022] SiBr 4 dissolved in [N 4441 In TFSI] ionic liquid, active material concentration is 0.25M, and working electrode is the gallium of 68%, the indium of 22% and the tin liquid alloy of 10%, auxiliary electrode is platinum electrode, and reference electrode is Ag / (10mM AgNO 3 acetonitrile solution). Constant voltage electrodeposition, the working voltage is -2.0V, the temperature is 100°C, after 10 hours of electrodeposition on the liquid electrode to obtain the product silicon, after the product and the liquid electrode are taken out of the electrolyte at the same time, they are washed with DMF for many times to ensure that the ion The liquid is washed, and then the crystalline silicon product is enriched into the organic phase with a mixed solution of anhydrous methanol and acetone, and the liquid metal electrode is transferred out. A small amount of liquid metal on the surface of the obtained product is removed by boiling in 10% hydrochloric acid solution. Clean the pr...

Embodiment 3

[0024] SiCl 4 Dissolved in [EMIMTFSI] ionic liquid, the active material concentration is 0.05M, the working electrode is 100% liquid gallium, the auxiliary electrode is a glassy carbon electrode, and the reference electrode is Ag / (10mM AgNO 3 acetonitrile solution). Constant voltage electrodeposition, the working voltage is -3.2V, the temperature is 110°C, after 10 hours of electrodeposition on the liquid electrode to obtain the product silicon, after the product and the liquid electrode are taken out of the electrolyte at the same time, they are washed with DMF for many times to ensure that the ion The liquid is cleaned, and then the crystalline silicon product is enriched into the organic phase with a mixed solution of anhydrous methanol and acetone equal in volume, and the liquid metal electrode is transferred out. A small amount of liquid metal on the surface of the obtained product is removed by boiling in 10% hydrochloric acid solution. Clean the product with water and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com