Microwave micro-plasma electron source

A micro-plasma and electron source technology, applied in the field of mass spectrometry instruments, can solve the problems of large power reflection, no integrated design of impedance matching structure, inability to stimulate and maintain plasma, etc., and achieves wide application range and expandable The effect of the range of detection substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

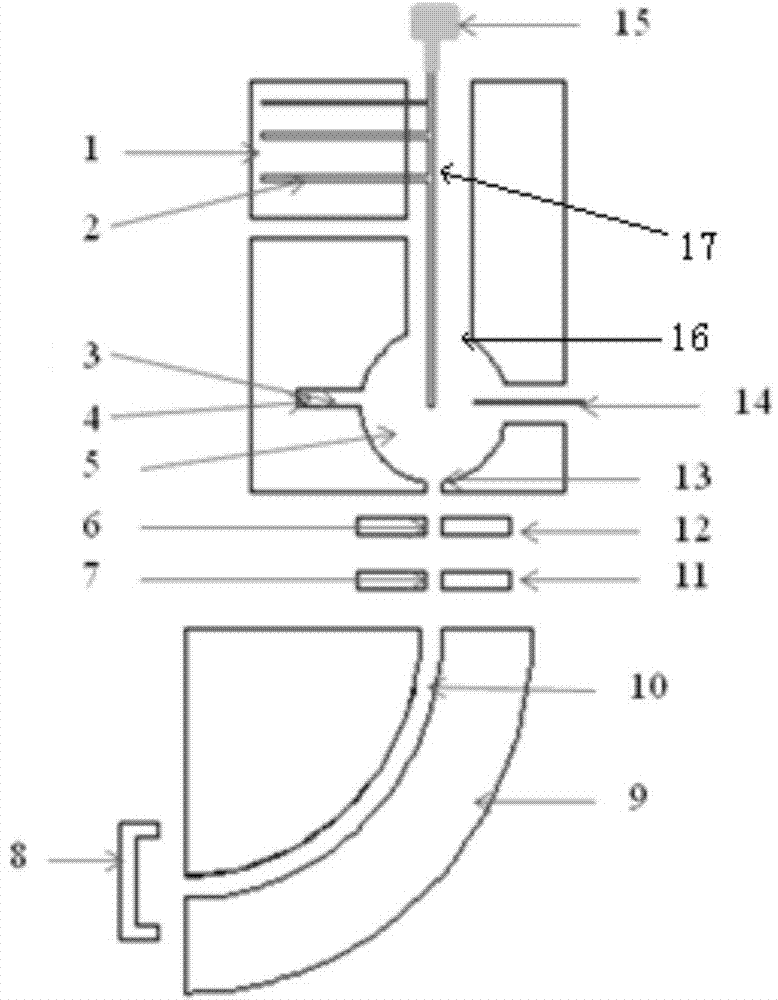

[0022] The electron beam provided by the invention has high energy and adjustable energy range, and can be applied to a micro-plasma electron source ( figure 1 ), and due to the characteristics of micro-electro-mechanical system (MEMS) processing technology, the integrated design and processing of ion source, mass analyzer, detector, etc. in the later stage can completely eliminate the analysis error caused by matching error.

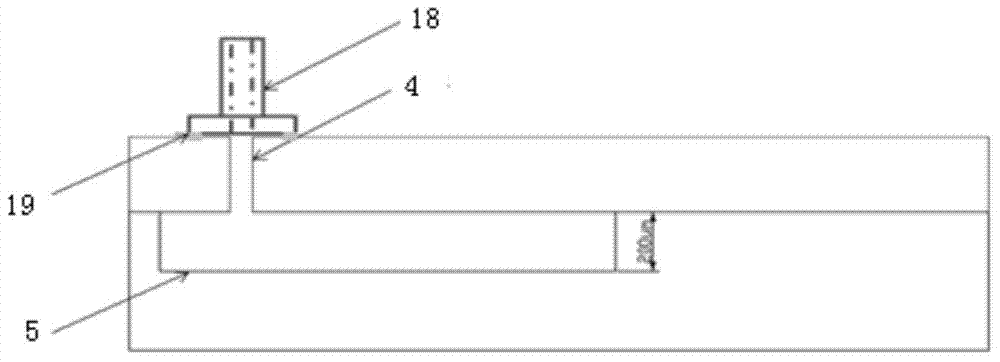

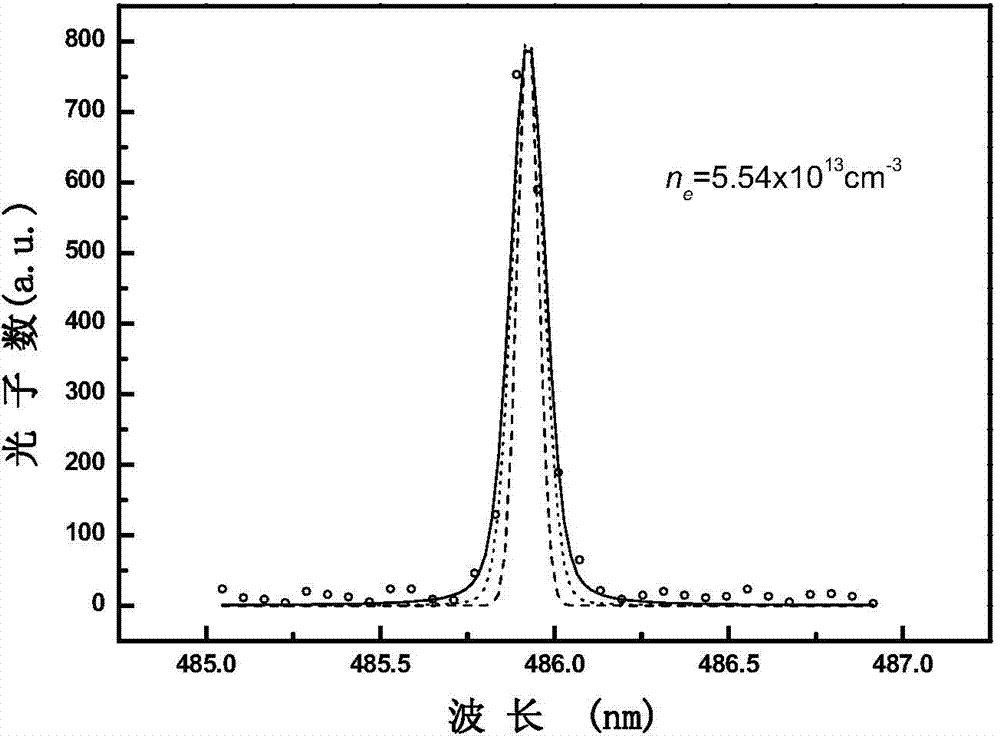

[0023] The microwave micro-plasma electron source is given high-voltage excitation to the argon gas in the plasma chamber by a high-voltage ceramic device, and through a microstrip resonator with a three-open-circuit branch structure, the 2.4-2.5GHz microwave frequency band and the power of 1W Coupled to argon gas to form a stable plasma; the plasma chamber is grounded, the electron acceleration and focusing lens are respectively applied with voltages of 10V and 80V, the energy filter is applied with a voltage of 32V, and the output electron energy is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com