Artificial feed for asparagus caterpillar, preparation of artificial feed and feeding method

A technology of artificial feed and beet armyworm, which is applied in animal feed, animal feed, food processing, etc., can solve the problems of unsuitable for large-scale breeding, easy wilting of vegetable leaves, high rate of abnormal pupae, etc., and achieve large-scale batch production The effect of feeding, improving the survival rate of larvae, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 (preparation 735g artificial feed)

[0043] Wheat bran: 30g; ash vegetable powder: 20g; corn flour: 10g; casein: 20g; cooked soybean powder: 20g; yeast powder: 15g; agar powder: 11g; distilled water: 600ml; cholesterol: 0.45g; soybean edible oil: 2.1 ml; Ascorbic acid: 4.2 g; Methylparaben: 1.75 g; Sorbic acid: 0.84 g.

Embodiment 2

[0044] Embodiment 2 feed preparation method:

[0045] During the implementation process, the homogenizer was soaked in 400mg / L chlorine water for 20 minutes for disinfection to prevent the feed from being infected with bacteria during the preparation process.

[0046] (1) Preparation of cooked soybean powder: buy high-quality soybeans from the market, bake them in an oven at 120°C for 2 hours, then grind them in a grinder, and grind them as finely as possible, then put the ground soybean powder on homemade kraft paper Sterilize the bag in a high-temperature humid heat sterilization pot for 1.5 hours, crush the sterilized bean cakes on newspaper, spread them evenly to dry, and put them back into kraft paper bags, label them and place them in a 5°C refrigerator Save for later use;

[0047] (2) Preparation of gray vegetable powder: wash the fresh gray vegetable leaves, dry them in an oven after drying naturally in the sun, then crush them through a 90-mesh sieve, take the leaf p...

Embodiment 3

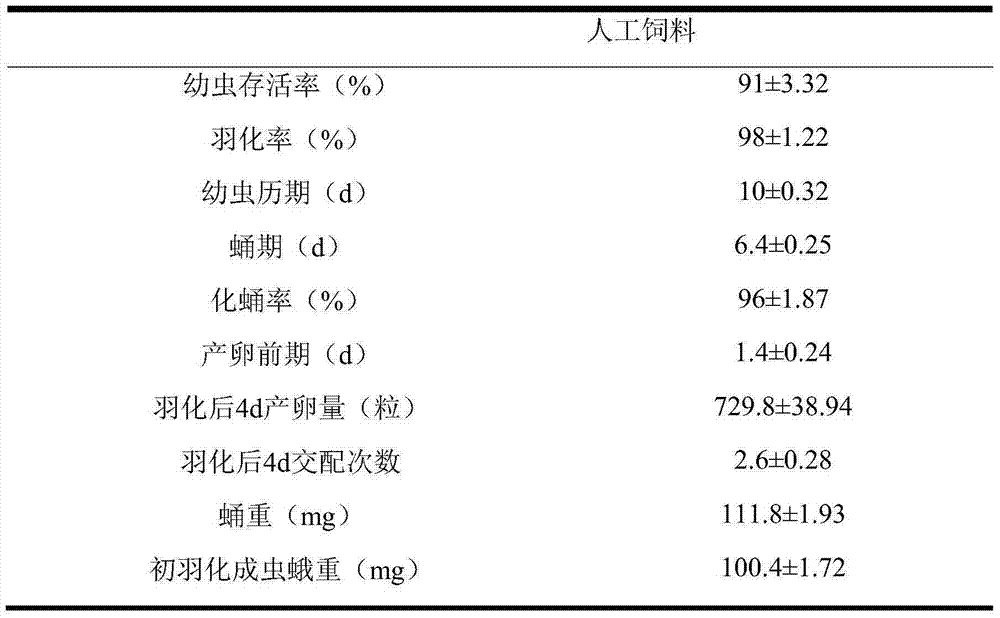

[0055] Implement the large-scale, long-term, subculture raising method of example 3 beet armyworm

[0056] The environmental conditions in the insect culture room for the artificial rearing of beet armyworm are as follows: the temperature is 27±1°C, the indoor relative humidity is 40%-50%, and the photoperiod is L14:D10. Under the irradiation for 2 hours, spray disinfection with 400mg / L disinfectant for 20 minutes, and open the window of the insect breeding room to ventilate once every 3 days. During the breeding process, also pay attention to the cleanliness and cleanliness of the room. If there are worms infected with bacteria or viruses in the middle, they should be cleaned out of the insect breeding room in time. Before raising insects, small brushes, tweezers, scissors, small spoons, etc. used for insect rearing should be sterilized by high temperature and humidity, and the brushes used should be as soft as possible.

[0057] (1) Eggs - newly hatched larvae: Cut the egg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com