Preparation method of blended and cross-linked polyvinyl alcohol (PVA) pervaporation membrane

A technology of cross-linked polyvinyl alcohol and pervaporation membrane, which is applied in the field of membrane separation, can solve the problems of restricting the application of PVA membranes, poor membrane permeability, and low operating efficiency, and achieves easy industrial production, high mechanical strength, and water solubility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] (2) Preparation of pervaporation membrane: Dissolve polyvinyl alcohol with a degree of polymerization of 1750±50 in water at 80~100°C, prepare a PVA solution with a mass concentration of 1%~10%, and add it to step (1) to prepare Water-soluble hyperbranched polymer with a mass concentration of 1% to 50%, stir and mix evenly, cool to room temperature, filter to remove impurities, add a crosslinking agent with a mass ratio of 0.5% to 10%, and adjust the mixed solution to PH=2, The coating solution can be obtained after static defoaming; wherein the chemical crosslinking agent is selected from glutaraldehyde, formaldehyde, terephthalaldehyde, maleic acid, adipic acid, succinic anhydride, pyromellitic anhydride Any one of them, the pH adjustment can be either sulfuric acid or hydrochloric acid;

[0025] (3) Scrape-coat the polyvinyl alcohol coating solution prepared in step (2) on the porous polymer base film with an average pore size of 50-100 μm, and put it in a vacuum at ...

Embodiment

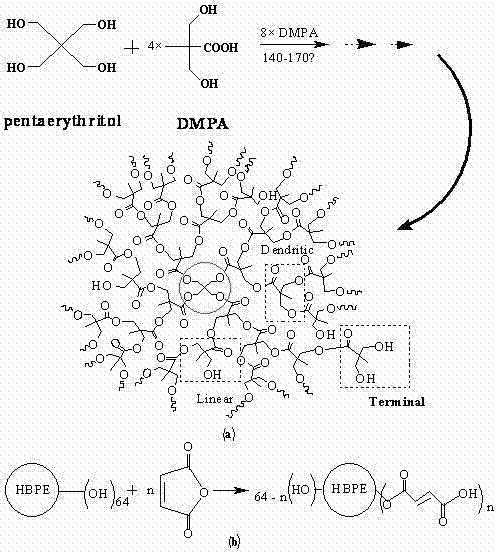

[0036] The water-soluble hyperbranched polymer is synthesized by the inventor, taking the synthesis of the fourth generation water-soluble hyperbranched polymer as an example, the specific steps are as follows:

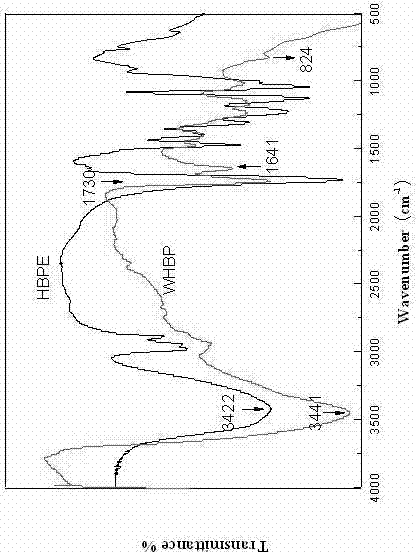

[0037] (1) Add DMPA (120mmol, 16.34g), pentaerythritol (10mmol, 1.36g) and catalyst p-TSA (0.08g) into a three-neck flask with stirring blade, nitrogen inlet and drying tube. Under mechanical stirring and nitrogen flow, the temperature was raised to 140 ~ 170 o c. After reacting at normal pressure for 2 hours, turn off the nitrogen gas, seal the three-neck flask and depressurize to 1.2kPa, stop the depressurization after 2 hours of reaction, and obtain the second generation hyperbranched polyester (HBPE-2); then weigh 21.8g of DMPA and p-TSA 0.12 g, put it into the three-necked flask, continue to pass nitrogen and raise the temperature to 140 ~ 170 ° C, turn off the nitrogen after 2 hours of normal pressure reaction, reduce the pressure to 1.2kPa and continue the rea...

Embodiment 1

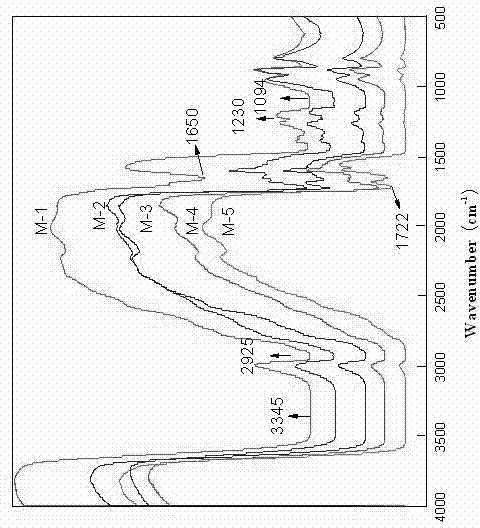

[0043] Dissolve 5g of PVA in 95g of water, the dissolution temperature is 90 ~ 95°C, add 0.25g of WHBP and stir for 4 hours until it is completely dissolved. After the mixed solution is cooled, let it stand for defoaming, add 0.25g of crosslinking agent (5% of the mass of PVA), Add sulfuric acid dropwise to adjust the mixed solution to PH = 2, stir slowly until the mixture is uniform to form a casting solution, and evenly scrape the casting solution on the PAN (polyacrylonitrile) ultrafiltration membrane. After the solvent evaporates naturally, put it in a vacuum drying oven Heat cross-linking at 100°C for 1h. The novel blended cross-linked pervaporation membrane is obtained.

[0044] The above-mentioned pervaporation membrane is used to separate n-butanol-water system, and the permeation flux is 233g / m 2 h, Separation factor 711.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com