Method for preparing nanocellulose at low energy consumption

A nano-cellulose and natural cellulose technology, applied in the field of cellulose derivatives, can solve the problems of organic solvent environmental pollution, high toxicity of chloroacetic acid, high equipment cost, etc., and achieve the effects of low environmental pollution, stable process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh 6 grams of sisal pulp and soak it with 18 ml of 5% sodium hydroxide aqueous solution at 20°C for 10 minutes to prepare a mixed solution.

[0021] (2) Take by weighing 0.55 gram of sodium hydroxide, mix it with 120 milliliters of ethanol and add it to the mixed solution prepared in step (1), under slow stirring, the reaction temperature is raised to 70°C; then add 1.85 gram of sodium chloroacetate, react 3 hours; then filtered, washed with distilled water to neutrality, and processed cellulose was obtained.

[0022] (3) adding the treated cellulose prepared in step (2) into 1000 milliliters of water to obtain a cellulose mixed solution, then shearing under high-speed stirring to form a gel, and finally diluting and centrifuging at a high speed, That is, the nanocellulose colloid is obtained.

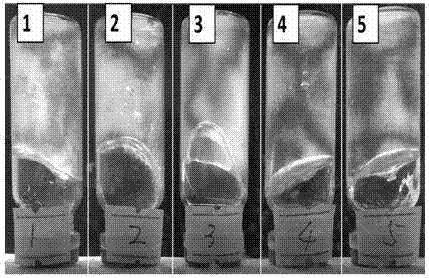

[0023] The product that the present embodiment makes can obtain its productive rate by measuring and be 99.0%; The digital photo of prepared nanocellulose (taken through...

Embodiment 2

[0025] (1) Weigh 6 g of sisal pulp and soak it with 18 ml of 7.7% sodium hydroxide aqueous solution at 20°C for 10 minutes to obtain a mixed solution.

[0026] (2) Add 120 ml of ethanol to the mixed solution prepared in step (1), heat the reaction to 70°C under slow stirring; add 1.85 g of sodium chloroacetate, and react for 3 hours; then filter and wash with distilled water until neutral , to obtain the treated cellulose.

[0027] (3) Add the treated cellulose prepared in step (2) into 600 ml of water to obtain a cellulose mixture, then stir it into a gel with a high-pressure homogenizer, and finally dilute and separate it by high-speed centrifugation to obtain a cellulose mixture. Obtain transparent nanocellulose colloid.

[0028] The product that the present embodiment makes can obtain its productive rate by measuring and be 98.9%; The digital photo of prepared nanocellulose (taken through polarized light) sees figure 1 In (2), it can be seen that under polarized light, t...

Embodiment 3

[0030] (1) Weigh 3 g of sisal pulp and soak it with 9 ml of 15% sodium hydroxide aqueous solution at 10°C for 1 minute to prepare a mixed solution.

[0031] (2) Measure 43.9 milliliters of ethanol and join in the mixed solution that step (1) makes, under slow stirring, reaction is warmed up to 50 ℃; Then add 0.9 gram of sodium chloroacetate, react for 4 hours; Filter then, wash with distilled water until Neutral, the prepared cellulose.

[0032] (3) Add the treated cellulose prepared in step (2) into 200 ml of water, then shear it under high-speed stirring, and form a gel, and finally dilute and separate it by high-speed centrifugation to obtain nano-cellulose colloid .

[0033] The product that the present embodiment makes can obtain its productive rate by measuring and be 91.8%; The digital photo of prepared nanocellulose (taken through polarized light) sees figure 1 In (3), it can be seen that under polarized light, there is a light and dark image, indicating that the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com