Method and culture device for coupling biogas fermentation with microalgae culture

A technology of microalgae cultivation and biogas fermentation, which is applied in the direction of supporting/immobilizing microorganisms, sterilization methods, enzymology/microbiology devices, etc., and can solve problems such as groundwater pollution and soil compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

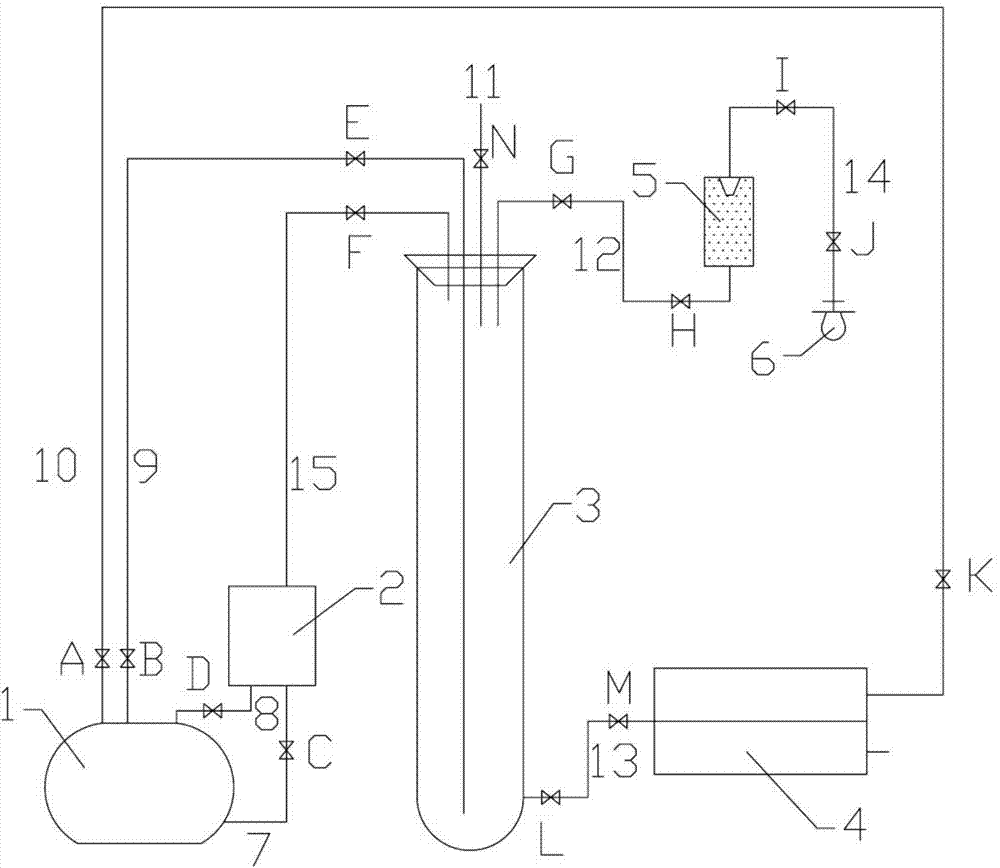

[0023] Such as figure 1 As shown, the cultivation device for coupling biogas fermentation and microalgae cultivation in this embodiment includes a biogas fermentation system 1, a filtration system 2, a microalgae cultivation reactor 3, a biodiesel extractor 4, a dehumidifier 5, and a biogas fermentation system 1 The bottom of the filter system is connected to the inlet of the filter system 2 through the biogas slurry delivery pipeline 7, the outlet of the filter system is connected to the microalgae cultivation reactor 3 through the culture solution delivery pipeline 15, and the residue outlet of the filter system is connected to the biogas fermentation system through the residue delivery pipeline 8. The upper part is connected, and a biogas delivery pipeline 9 is provided on the upper part of the biogas fermentation system, and the biogas delivery pipeline leads to the bottom of the microalgae cultivation reactor 3, and a purified biogas delivery pipeline 12 is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com