Method for recovering lead from waste lead storage battery

The technology of a waste lead storage battery and a recovery method is applied in the field of lead recovery and lead recovery in waste lead storage batteries, which can solve the problems of low lead recovery rate, aggravated environment and high energy consumption, and achieves high vertical recovery rate and low smoke dust rate. , the effect of low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

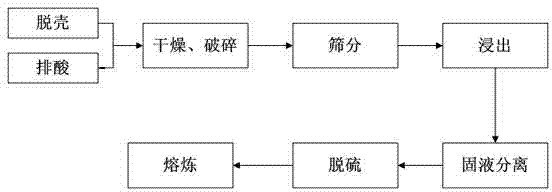

[0022] Such as figure 1 Shown, the concrete steps of the recovery method of lead in waste lead storage battery of the present invention are as follows:

[0023] 1. Transport the waste lead-acid battery to the dismantling machine to remove the shell and remove the waste acid inside; then send it to the dryer for drying treatment to remove the moisture inside the waste lead-acid battery;

[0024] 2. Use a hammer crusher to crush the dried waste lead-acid batteries to a particle size of 4-9mm;

[0025] 3. Sieve the waste lead-acid battery fragments, the sieve is waste plastics, grids and connectors, the sieve is waste lead paste, and the lead paste is a mixture of lead, lead oxide and lead sulfate;

[0026] 4. Oxidatively leaching the waste lead paste with nitric acid to obtain a leachate, the content of lead in the leachate is 210g / L; the concentration of nitric acid is 3M, the leaching temperature is 93°C, and the leaching time is 150min;

Embodiment 2

[0033] The concrete steps of the recovery method of lead in waste lead storage battery of the present invention are as follows:

[0034] 1. Transport the waste lead-acid battery to the dismantling machine to remove the shell and remove the waste acid inside; then send it to the dryer for drying treatment to remove the moisture inside the waste lead-acid battery;

[0035] 2. Use a hammer crusher to crush the dried waste lead-acid batteries to a particle size of 4-9mm;

[0036] 3. Sieve the waste lead-acid battery fragments, the sieve is waste plastics, grids and connectors, the sieve is waste lead paste, and the lead paste is a mixture of lead, lead oxide and lead sulfate;

[0037] 4. Oxidatively leaching waste lead paste with nitric acid to obtain a leach solution, the content of lead in the leach solution is 230g / L; the concentration of nitric acid is 4M, the leaching temperature is 94°C, and the leaching time is 170min;

[0038] 5. Add sodium sulfate to the leachate obt...

Embodiment 3

[0044] The concrete steps of the recovery method of lead in waste lead storage battery of the present invention are as follows:

[0045] 1. Transport the waste lead-acid battery to the dismantling machine to remove the shell and remove the waste acid inside; then send it to the dryer for drying treatment to remove the moisture inside the waste lead-acid battery;

[0046] 2. Use a hammer crusher to crush the dried waste lead-acid batteries to a particle size of 4-9mm;

[0047] 3. Sieve the waste lead-acid battery fragments, the sieve is waste plastics, grids and connectors, the sieve is waste lead paste, and the lead paste is a mixture of lead, lead oxide and lead sulfate;

[0048] 4. Oxidatively leaching waste lead paste with nitric acid to obtain leachate, the content of lead in the leachate is 220g / L; the concentration of nitric acid is 5M, the leaching temperature is 96°C, and the leaching time is 200min;

[0049] 5. Add sodium sulfate to the leachate obtained, the amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com