FSW (Friction Stir Welding) method of nickel-plated aluminum alloy plate doped by rare-earth lanthanum

An aluminum alloy sheet, friction stir welding technology, applied in welding equipment, metal processing, non-electric welding equipment and other directions, can solve the problems of poor corrosion resistance and toughness, and the change of metallographic structure is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

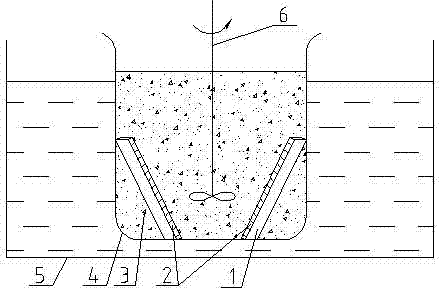

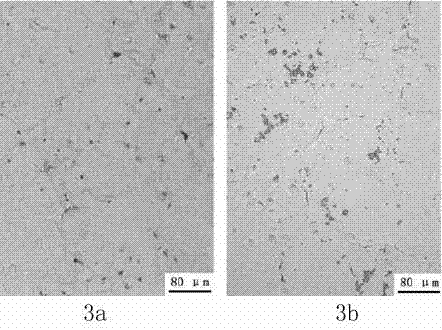

[0035] Embodiment 1: first prepare chemical plating solution according to the ratio described in the technical scheme, put the weighed sodium acetate and sodium hypophosphite into the beaker, put into a small amount of water, stir; and sodium citrate into the mixed acid, heat and stir until completely dissolved, and finally put the oxide of rare earth lanthanum into the electroless plating solution, and measure the pH value of the solution, adjust the pH value to 3 with the prepared sodium hydroxide solution ~5. Use a digitally controlled thermostat to control the bath temperature to 45±1°C.

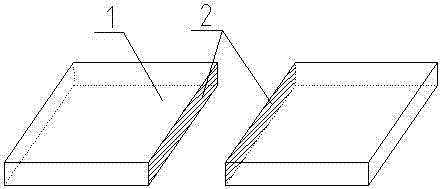

[0036] The model of the aluminum alloy plate is 6061, the size is 100mm×200mm×1mm, and it is pretreated. The steps are alkali cleaning and degreasing—water washing—pickling activation—water washing—drying, and then the surface is polished with 1000# sandpaper, and then gold It is finely ground with sandpaper and used as a base for electroless nickel plating solution.

[0037] Treat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com