Composite catalyst and preparation method of polytrimethylene terephthalate

A technology of polytrimethylene terephthalate and terephthalic acid, which is applied in the chemical industry, can solve the problems that the intrinsic viscosity cannot be satisfied, is not suitable for industrial application, and the reaction is difficult to control, and can reduce the coordination and complexing ability, Non-toxic price, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

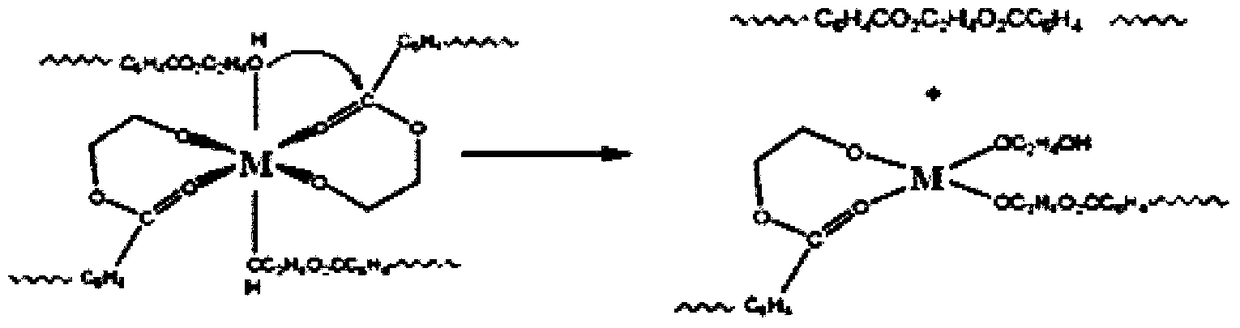

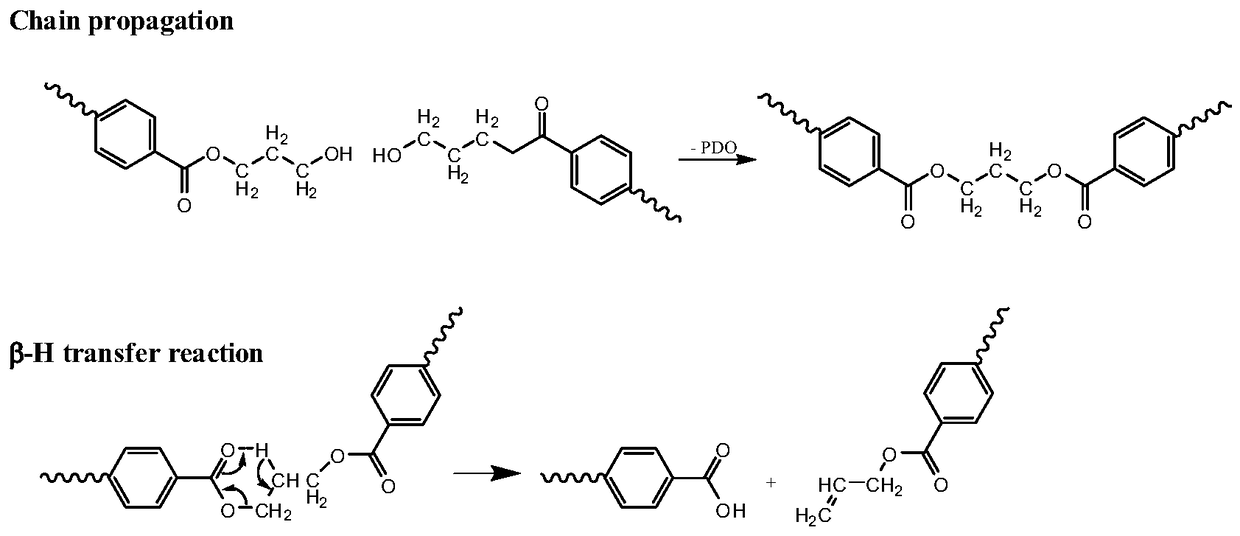

Method used

Image

Examples

Embodiment approach

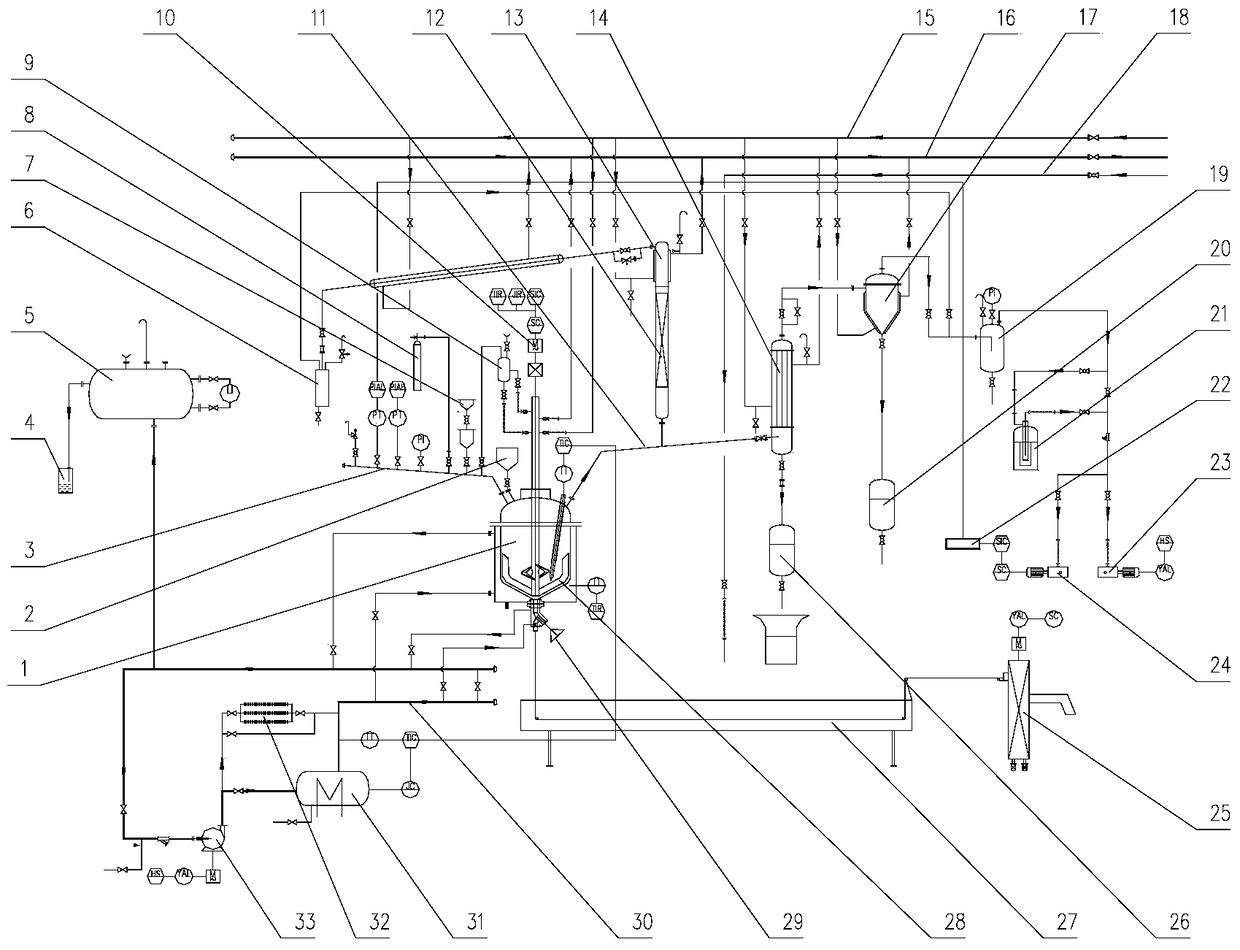

[0038] image 3 It shows the experimental equipment and corresponding process flow for preparing polytrimethylene terephthalate with terephthalic acid and 1,3-propanediol as raw materials. The reactor 1 is equipped with a stirrer 28, and the reactor is provided with a feeding hopper 2 , the measured material is sent into the reactor through the feeding hopper, and the entire reaction process of beating, esterification and polycondensation (initial polycondensation and final polycondensation) is completed in the reactor, and an agitator drive motor 10 is arranged above the reactor. Drive the agitator to work according to the process needs. In a preferred embodiment, the end point of the polycondensation reaction can be judged by the electric current of the stirrer driving motor. This judgment method is simple, convenient and effective, and is convenient for automatic control. The bearing part of the agitator should be provided with a shaft seal and equipped with a shaft seal s...

Embodiment 1

[0054]Embodiment 1: first utilize high-purity nitrogen to displace reactor 2 times, under the protection of high-purity nitrogen, drop into terephthalic acid 2492g (15mol), 1,3-propanediol 1484g (19.5mol), and add composite catalyst tetra-titanate Butyl ester / bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, the amount of n-butyl titanate is 2000ppm, the amount of bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite is 2200ppm. Elevate the temperature to carry out the esterification reaction, the temperature is 235°C, and the pressure is 200kPa. Esterification water is distilled out at the same time. After the theoretical amount of esterification water is removed, the temperature is raised to 250°C, and the absolute pressure is slowly reduced to about 2kPa, and enters the pre-condensation stage for about 30 minutes. After the pre-polycondensation is completed, further vacuumize and enter the final polycondensation stage. The temperature is kept at 250°C, and the pre...

Embodiment 2

[0055] Example 2: First, use high-purity nitrogen to replace the reactor for 2 times, under the protection of high-purity nitrogen, put in 2492g (15mol) of terephthalic acid, 1712g (22.5mol) of 1,3-propanediol, and add the composite catalyst tetra-titanate Butyl ester / bis(2,4,6-tri-tert-butylphenyl)pentaerythritol diphosphite, the amount of n-tetrabutyl titanate is 1500ppm, bis(2,4,6-tri-tert-butylphenyl)pentaerythritol diphosphite Phosphite consumption is 2000ppm. Elevate the temperature to carry out the esterification reaction, the temperature is 235°C, and the pressure is 200kPa. Esterification water is distilled out at the same time. After the theoretical amount of esterification water is removed, the temperature is raised to 250°C, and the absolute pressure is slowly reduced to about 2kPa, and enters the pre-condensation stage for about 30 minutes. After the pre-polycondensation is completed, further vacuumize and enter the final polycondensation stage. The temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com