Method for preparing wood frog skin collagen

A collagen and frog skin technology, applied in the biological field, can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

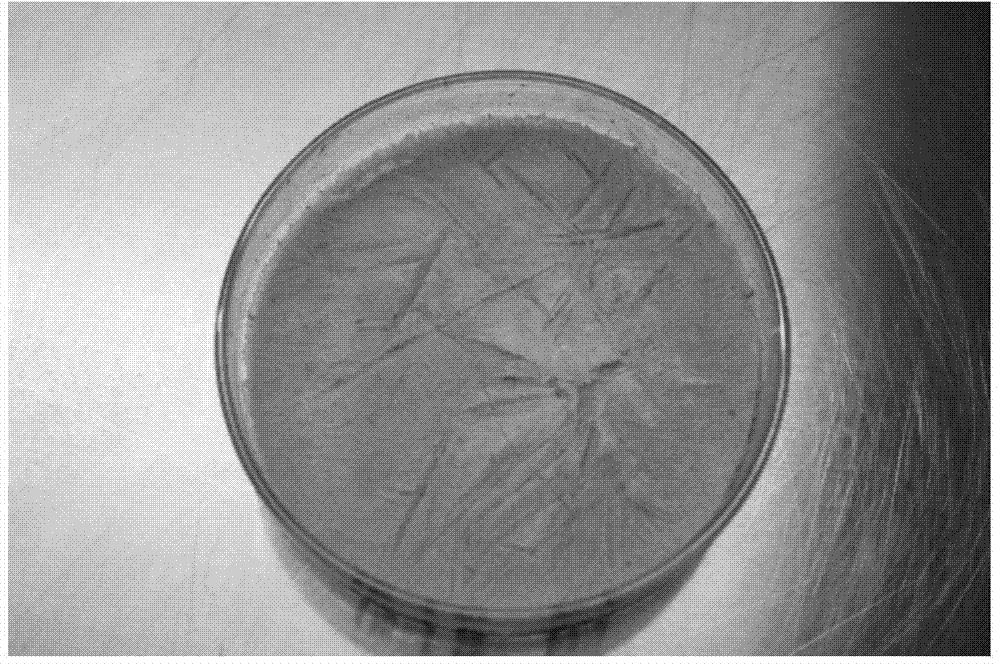

Image

Examples

Embodiment 1

[0023] (1) Preprocessing:

[0024] Take the freshly stripped Rana skin, remove the subcutaneous tissue and adhesions, wash with tap water, dry naturally at room temperature, and pulverize. All extraction operations were carried out at 4°C.

[0025] Weigh 10 g of crushed dry Rana skin powder, add it into 100 mL of 0.3 mol / L NaOH aqueous solution, keep stirring at a slow speed for 24 h, and replace the mixed solution every 4 h. Wash the sample with 10 times the volume of distilled water (4°C) until neutral.

[0026] Add the water-washed to neutral wood frog skin sample to 100mL 20% n-butanol solution to degrease, keep stirring at a slow speed for 24h, and replace the mixed solution every 4h. The samples were washed three times with 10 volumes of distilled water (4°C).

[0027] (2) Extraction of acid-soluble collagen:

[0028] Add the pretreated wood frog skin sample to 100mL 1.0mol / L acetic acid solution. Under the power of 200W, microwave irradiation for 1min. Afterwards,...

Embodiment 2

[0035] (1) Preprocessing:

[0036] Take the freshly stripped Rana skin, remove the subcutaneous tissue and adhesions, wash with tap water, dry naturally at room temperature, and pulverize. All extraction operations were carried out at 4°C.

[0037] Weigh 10 g of crushed dry Rana skin powder, add it into 500 mL of 0.3 mol / L NaOH aqueous solution (containing 3% hydrogen peroxide), continue stirring at a slow speed for 120 h, and replace the mixed solution every 8 h. Wash the sample with 10 times the volume of distilled water (4°C) until neutral.

[0038] Add the water-washed to neutral wood frog skin sample into 500mL 20% n-butanol solution to degrease, keep stirring at a slow speed for 72h, and replace the mixed solution every 8h. The samples were washed three times with 10 volumes of distilled water (4°C).

[0039] (2) Extraction of acid-soluble collagen:

[0040] Add the pretreated wood frog skin sample to 500mL 1.0mol / L acetic acid solution. Under the power of 800W, the...

Embodiment 3

[0048] (1) Preprocessing:

[0049] Take the freshly stripped Rana skin, remove the subcutaneous tissue and adhesions, wash with tap water, dry naturally at room temperature, and pulverize. All extraction operations were carried out at 4°C.

[0050] Weigh 10 g of crushed dry Rana skin powder, add it into 300 mL of 0.3 mol / L NaOH aqueous solution (containing 1.5% hydrogen peroxide), continue stirring at a slow speed for 96 h, and replace the mixed solution every 6 h. Wash the sample with 10 times the volume of distilled water (4°C) until neutral.

[0051] Add the water-washed to neutral wood frog skin sample to 300mL 20% n-butanol solution to degrease, keep stirring at a slow speed for 48h, and replace the mixed solution every 6h. The samples were washed three times with 10 volumes of distilled water (4°C).

[0052] (2) Extraction of acid-soluble collagen:

[0053] Add the pretreated Rana skin sample to 300mL 1.0mol / L acetic acid solution. Under the power of 500W, the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com