Hollow fiber ceramic membrane production method

A ceramic membrane and fiber technology is applied in the field of preparation of in-situ composite carbon-toughened YSZ hollow fiber ceramic membranes, which can solve the problems of unsatisfactory fracture toughness, high production cost, complicated and tedious processes, and achieves good adsorption effect and avoids high temperature. Sintering, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Select 3YSZ and test the cross-flow filtration effect of the hollow fiber ceramic membrane module prepared by the preparation method proposed by the present invention, add unfiltered raw water into the membrane module, and conduct Escherichia coli on the water permeated from the outer wall of the membrane module. The removal rate, chloride ion removal rate, and lead ion removal rate were analyzed and tested, and the removal rate of Escherichia coli was >99.99%; the removal rate of residual chloride ion in water was >99.9%, and the removal rate of lead ion was >99.9%.

Embodiment 2

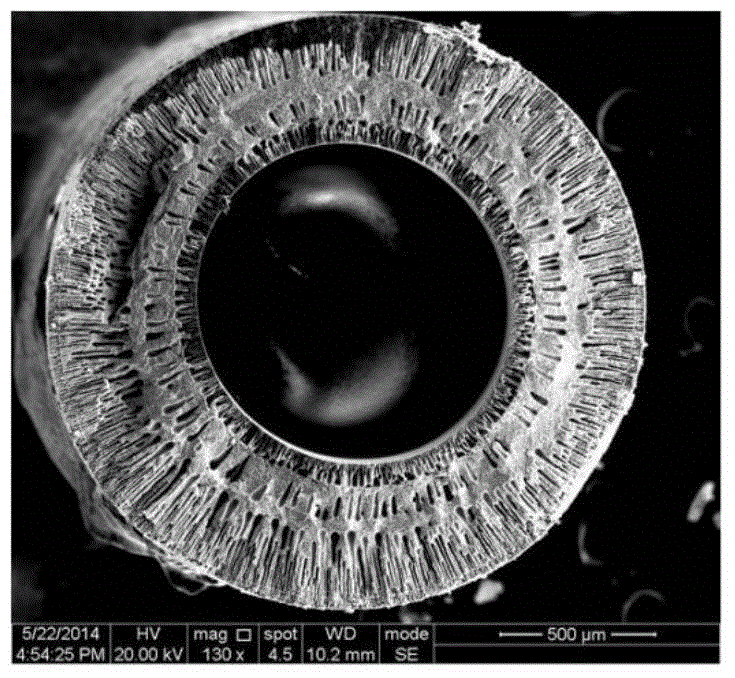

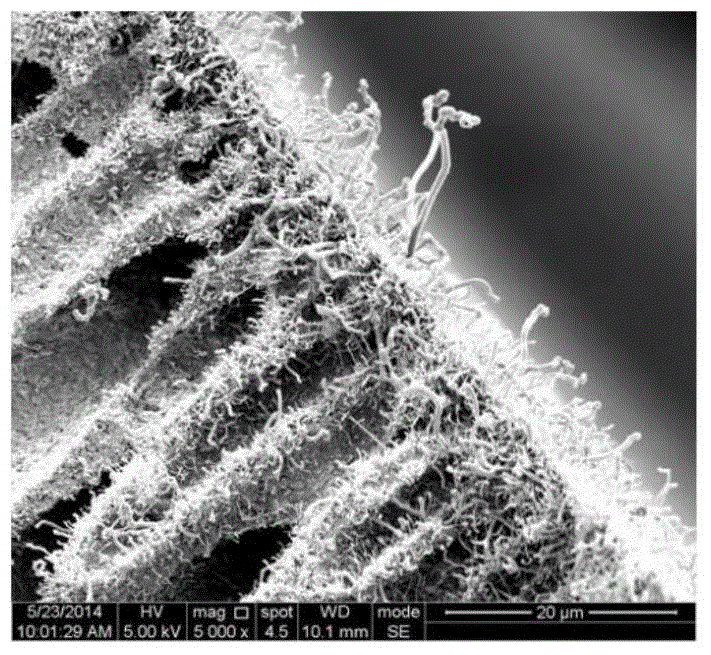

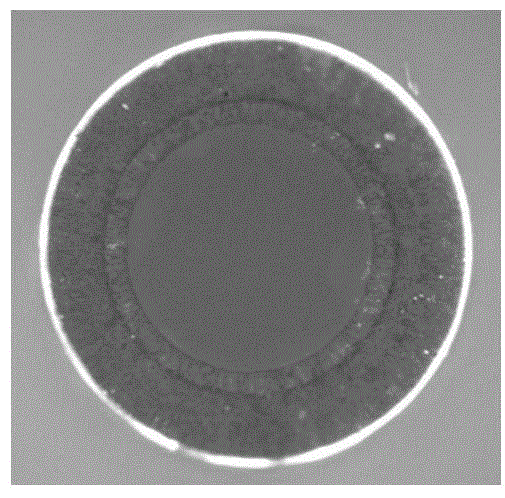

[0023] Select 3YSZ and carry out external flame and external combustion treatment on the hollow fiber ceramic membrane module prepared by the preparation method proposed by the present invention to prepare a hollow fiber membrane with a C / YSZ double-layer structure ratio of 1:1, and detect its porosity and water flow, it is found that the open porosity can reach 46.8%, and the water flow is 4.18m 3 / (m 2 .h.bar).

Embodiment 3

[0025] Select 5YSZ and test the cross-flow filtration effect of the hollow fiber ceramic membrane module prepared by the preparation method proposed by the present invention, add unfiltered raw water into the membrane module, and conduct Escherichia coli on the water permeated from the outer wall of the membrane module. The removal rate, chloride ion removal rate, and lead ion removal rate were analyzed and tested, and the removal rate of Escherichia coli was >99.00%; the removal rate of residual chloride ion in water was >99.0%, and the removal rate of lead ion was >99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com