Preparation of AlPo-18 zeolite membrane and method for separating CO2 and N2 by adopting AlPo-18 zeolite membrane

A technology of alpo-18 and separation method, applied in the direction of separation method, molecular sieve and alkali exchange phosphate, semi-permeable membrane separation, etc., can solve the problem of low selectivity, achieve good separation performance, high separation efficiency and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

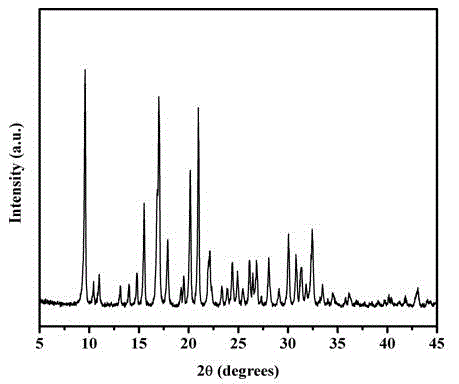

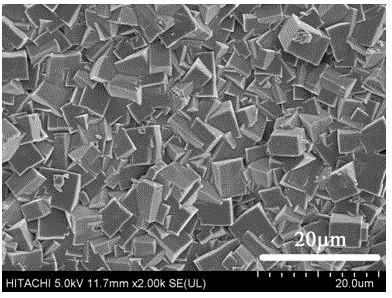

[0026] (1) Seed crystal preparation: Mix tetraethylammonium hydroxide (TEAOH), aluminum isopropoxide, phosphoric acid and water to form a stable sol, and the molar ratio of each component is P 2 o 5 / Al 2 o 3 =3.16, TEAOH / Al 2 o 3 =6.32, H 2 O / Al 2 o 3 =186. After aging for 2 hours, the sol was transferred to a polytetrafluoroethylene-lined autoclave, at 150 o C temperature hydrothermal synthesis 20h. The reaction was quenched with cold water, and the product was separated by centrifugation and washed with deionized water to neutrality to obtain AlPO-18 aluminum phosphorus molecular sieve seeds with AEI topology.

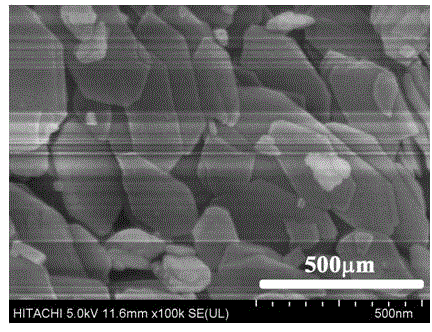

[0027] (2) Support body pretreatment: Porous tubular alumina ceramic tube is used as the support body, with an average pore diameter of 1.3 μm, an inner diameter and an outer diameter of 8 mm and 12 mm, respectively, a length of 100 mm, and a porosity of 35%. The outer wall of the support body was polished smooth by 800-mesh SiC, cleaned ultrasonically, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com