Denitration catalyst, preparation method thereof, and flue gas denitration method

A denitration catalyst and flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of narrow activity temperature window, poor thermal stability, difficult industrial application, etc., and achieve wide and low temperature activity. The effect of temperature range, strong thermal stability and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

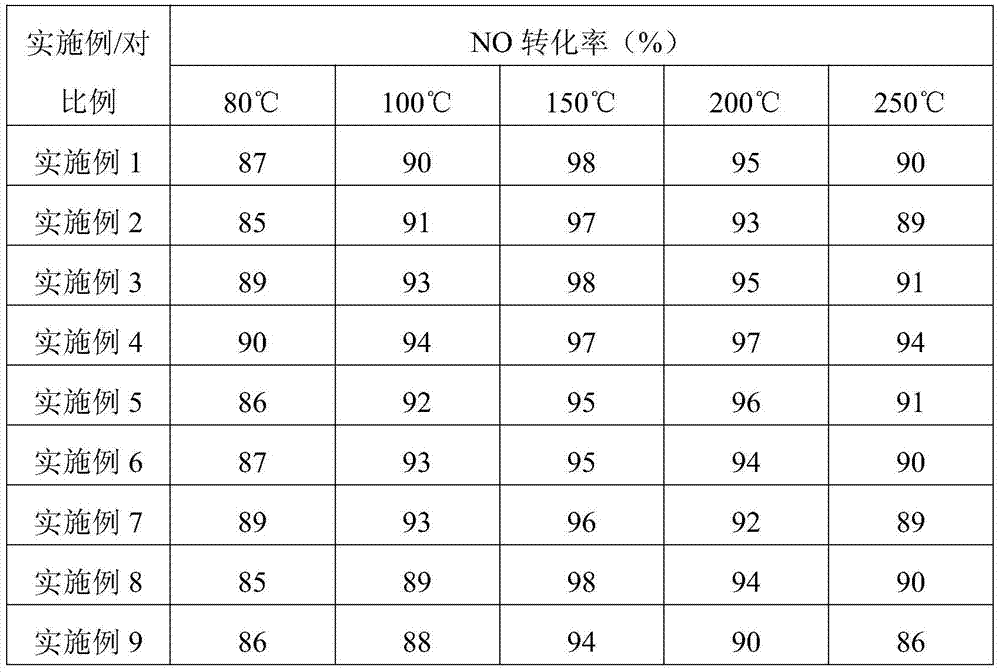

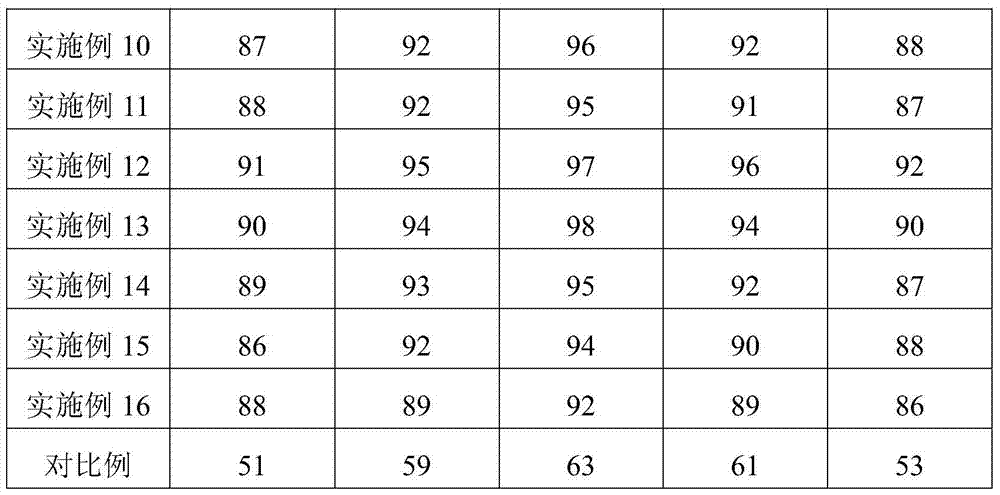

Examples

Embodiment 1

[0054] (1) Carrier pretreatment

[0055] The titanium dioxide is calcined at 200°C for 2 hours to remove impurities. After the treatment, it is placed in a desiccator for use. The TiO after removal 2 The purity is 95.7%, and the specific surface is 80.656m 2 / g.

[0056] (2) Doping of molybdenum oxide

[0057] 0.001molNa 2 MoO 4 2H 2 O is dissolved in the oxalic acid solution that 200ml concentration is 0.005mol / L, the TiO prepared by 0.1mol step (1) 2 Add it into the above molybdenum salt solution, stir evenly for 2 hours, then ultrasonically impregnate the slurry at 20KHz for 50 minutes, and then dry it in an oven at 105°C for 12 hours; take it out and grind it into a 40-60 mesh powder, and calcinate it in a muffle furnace at 350°C 3h, prepared MoO X / TiO 2 Carrier, MoO X Fully doped in TiO 2 Among them, the specific surface of the carrier is 98.656m 2 / g.

[0058] (3) Loading of active components

[0059] The raw material of the active component is MnSO 4 ·H ...

Embodiment 2

[0062] (1) Carrier pretreatment

[0063] The titanium dioxide is calcined at 200°C for 2 hours to remove impurities. After the treatment, it is placed in a desiccator for use. The TiO after removal 2 The purity is 95.7%, and the specific surface is 80.656m 2 / g.

[0064] (2) Doping of molybdenum oxide

[0065] 0.0025molNa 2 MoO 4 2H 2 O is dissolved in the ammonia solution of 0.0125mol / L in 200ml concentration, the TiO prepared by 0.1mol step (1) 2 Add it into the above molybdenum salt solution, stir evenly for 4 hours, then ultrasonically impregnate the slurry at 30KHz for 20 minutes, then dry it in an oven at 125°C for 14 hours; take it out and grind it into a 40-60 mesh powder, and calcinate it in a muffle furnace at 500°C 2h, prepared MoO X / TiO 2 carrier, the specific surface of the carrier is 102.314m 2 / g.

[0066] (3) Loading of active components

[0067] The raw material of the active component is MnCl 2 4H 2 O and Ce(NO 3 ) 3 ·6H 2 O, calculate the re...

Embodiment 3

[0070] (1) Carrier pretreatment

[0071] The titanium dioxide is calcined at 350°C for 2 hours to remove impurities. After the treatment, it is placed in a desiccator for use. The TiO after removal 2 The purity is 97.1%, and the specific surface is 90.521m 2 / g.

[0072] (2) Doping of molybdenum oxide

[0073] 0.003molNa 2 MoO 4 2H 2 O is dissolved in the citric acid solution that 200ml concentration is 0.015mol / L, the TiO prepared by 0.1mol step (1) 2 Add it into the above molybdenum salt solution, stir evenly for 3 hours, then ultrasonically impregnate the slurry at 10KHz for 150 minutes, then dry it in an oven at 150°C for 12 hours; take it out and grind it into 40-60 mesh powder, and calcinate it in a muffle furnace at 700°C 1h, prepared MoO X / TiO 2 carrier, the specific surface of the carrier is 113.213m 2 / g.

[0074] (3) Loading of active components

[0075] The raw material of the active component adopts manganese nitrate solution and Ce(NO 3 ) 3 ·6H 2 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com