Preparation method of ammonium perchlorate and crown ether eutectic oxidant

A technology of ammonium perchlorate and oxidizing agent, which can be used in ammonium perchlorate composition, offensive equipment, non-explosive/non-thermal agent components, etc. problems, to achieve the effect of reducing sensitivity, efficiently reducing hygroscopicity, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

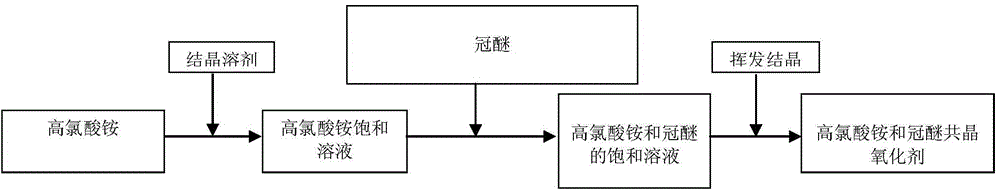

[0026] At room temperature, 40ml of acetone was added into the three-necked flask, then 2g of ammonium perchlorate was added under stirring, dissolved and filtered to obtain a saturated solution of ammonium perchlorate. Then add 3g of crown ether, stir, dissolve, filter, put the filtrate in a beaker, then put it still in a constant temperature incubator at 30°C, let the solvent evaporate, precipitate crystals, and dry to obtain ammonium perchlorate and crown ether eutectic oxidant.

Embodiment 2

[0028] At room temperature, 50ml of methyl ethyl ketone was added into a three-necked flask, and then 2.5g of ammonium perchlorate was added under stirring, dissolved, and filtered to obtain a saturated solution of ammonium perchlorate. Then add 3.5g crown ether, stir, dissolve, filter, put the filtrate in a beaker, and then put it still in a constant temperature incubator at 35°C, let the solvent evaporate, precipitate crystals, and dry to obtain ammonium perchlorate and crown ether eutectic oxidant .

Embodiment 3

[0030] At room temperature, 60ml of ethanol was added into the three-necked flask, then 3.0g of ammonium perchlorate was added under stirring, dissolved and filtered to obtain a saturated solution of ammonium perchlorate. Then add 5.5g crown ether, stir, dissolve, filter, and put the filtrate in a beaker. Then keep it still in a constant temperature incubator at 35°C, let the solvent evaporate, precipitate crystals, and dry to obtain ammonium perchlorate and crown ether eutectic oxidant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com