Method for preparing persimmon tannins with high micromolecular tannin content from persimmons

A technology of small molecules and persimmons, which is applied in the field of preparation of persimmon tannins with high content of small molecule tannins, which can solve problems such as the influence of sulfate radical content, cumbersome operation process, and impact on product content and yield, and achieve high-efficiency cell wall breaking , uniform particle size distribution, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

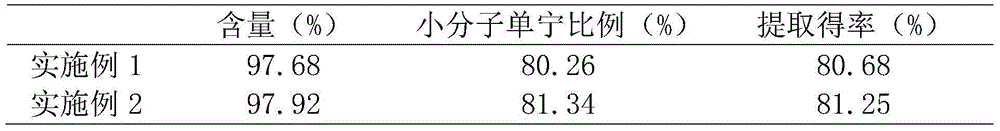

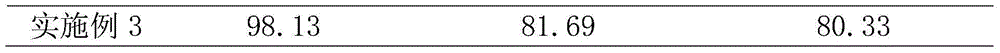

Embodiment 1

[0021] A method for preparing persimmon tannins with high content of small molecule tannins from persimmons, comprising the steps of:

[0022] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0023] 2) High-pressure micro-jet micro-grinding treatment: add 50kg of pure water to the crushed persimmons, process it with a high-speed shear emulsifier for 10 minutes at a speed of 12000r / min, and then use a high-pressure micro-jet ultra-fine pulverizer to process it at 25°C , the treatment pressure is 120MPa, and the number of treatments is 3 times to obtain a paste slurry;

[0024] 3) Fermentation: The paste slurry obtained in step 2) is subjected to ultra-high temperature instantaneous sterilization, then adjusted to pH 7.0, inserted into the cultured mature Lactobacillus bulgaricus liquid strain at 10% by volume, and put into a fermenter for fermentation , the fermentation temperature is 35-37°C, and the fermentation t...

Embodiment 2

[0029] A method for preparing persimmon tannins with high content of small molecule tannins from persimmons, comprising the steps of:

[0030] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0031] 2) High-pressure micro-jet ultra-fine pulverization treatment: add 60kg of pure water to the crushed persimmons, process them with a high-speed shear emulsifier for 20 minutes at a speed of 10,000r / min, and then use high-pressure micro-jet ultra-fine pulverization equipment for processing at 25°C , the treatment pressure is 100MPa, and the number of treatments is 2 times to obtain a paste slurry;

[0032] 3) Fermentation: The paste slurry obtained in step 2) is subjected to ultra-high temperature instantaneous sterilization, then adjusted to pH 6.5, and inserted into a cultured mature Lactobacillus acidophilus liquid strain at 12% by volume, and put into a fermenter Fermentation, the fermentation temperature is 35-37°C,...

Embodiment 3

[0037] A method for preparing persimmon tannins with high content of small molecule tannins from persimmons, comprising the steps of:

[0038] 1) Raw material processing: 10kg of persimmons that are seven to eighty percent ripe are washed and crushed;

[0039]2) High-pressure micro-jet ultra-fine pulverization treatment: add 50kg of pure water to the crushed persimmons, process them with a high-speed shear emulsifier for 15 minutes at a speed of 8000r / min, and then use high-pressure micro-jet ultra-fine pulverization equipment for processing at 25°C , the treatment pressure is 80MPa, and the number of treatments is 2 times to obtain a paste slurry;

[0040] 3) Fermentation: The paste slurry obtained in step 2) is subjected to ultra-high temperature instantaneous sterilization, placed in a sealed fermentation tank, and activated pectinase, apple amylase, and pectin lyase are added for enzymolysis. The enzymolysis time is 25 minutes, the enzymolysis temperature is 43-45°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com