Method for preparing polyimide film

A polyimide film and polyimide resin technology, which is applied in the field of polyimide resin preparation, can solve the problem of yellowing, affecting the light transmittance, yellowness index and haze of polyimide film, etc. problem, to achieve the effect of low yellowness index and haze, easy processing and production, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

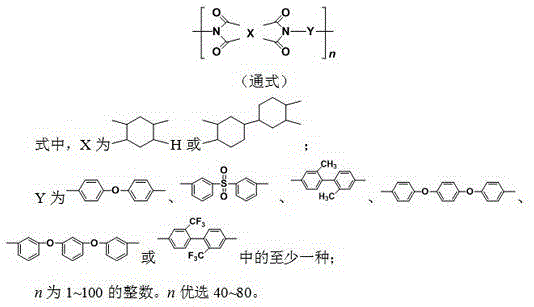

[0027] A kind of preparation method of polyimide film, it comprises the steps:

[0028] (1) In a high-pressure reactor equipped with mechanical stirring, thermometer, inert gas inlet and outlet, and Dean-Stark water trap, dissolve the diamine compound in N,N - Dimethylformamide (DMF) or N,N - In dimethylacetamide (DMAc) solvent;

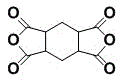

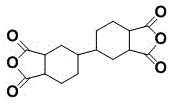

[0029] (2) Pass inert gas into the autoclave and add dianhydride compound;

[0030] (3) After all the reactants are dissolved, add organic base catalyst and dehydrating agent, and seal the reaction kettle;

[0031](4) Heating to raise the temperature to 120~150°C, and carry out reflux dehydration for 3~10 hours. After the dehydration is completed, remove the toluene and continue to raise the temperature at a reaction temperature of 160~190°C and a reaction pressure of 0.1~1 MPa. Carry out imidization reaction, the time is 1-10 hours, obtain polyimide resin;

[0032] (5) Dissolving the polyimide resin prepared in step (4) in an organic solvent to ...

Embodiment

[0061] Example 1 A kind of preparation method of polyimide film, it comprises the steps:

[0062] 20.024 g (100 mmol) of ODA and 60 g of DMAc were added to a 1000 mL autoclave equipped with a nitrogen inlet and equipped with a thermometer, water separator, condenser and mechanical stirring. After stirring at room temperature to dissolve completely, under nitrogen protection, add 22.417 g (100 mmol) HPMDA and 18.8 g DMAc, adjust the solid content to 35% (mass percentage) with DMAc, and add 0.5 g isoquinoline With 250 g xylene, heat up to reflux, and divide the water for 4 hours. Then xylene is released from the water separator. The reaction system was airtight and continued to heat up to 165 o C. At this time, the system pressure is 0.12 MPa, continue to react for 6 h, stop the reaction, remove the pressure, cool to room temperature, slowly pour the obtained light yellow viscous solution into a large amount of ethanol to obtain a white filamentous resin, 100 o C was dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com