Method for producing citric acid by using lignocellulose raw material

A technology of lignocellulose and citric acid, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of non-industrialization, low citric acid output, etc., and achieves low cost, low substrate cost, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

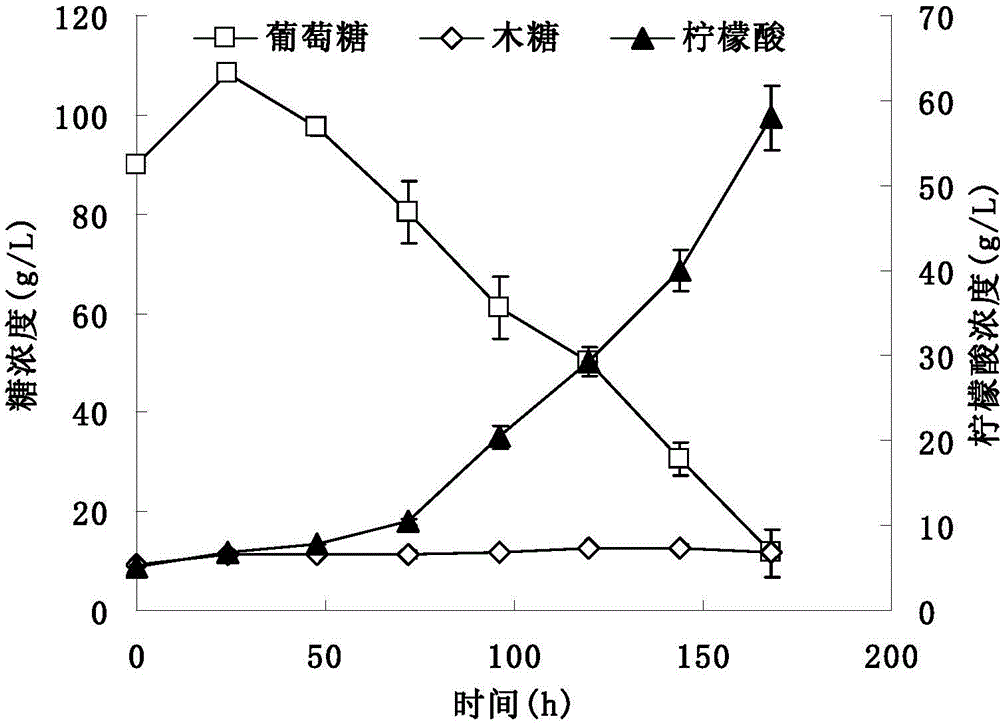

[0032] Mix the dried corn stalks with 5% dilute sulfuric acid solution at a mass ratio of 2:1, and then pretreat them at 190°C and 1.2MPa for 3 minutes; The used bacterial species Amorphotheca resinae ZN1 (its preservation number CGMCC7452) was detoxified in a solid state at 25°C for 10 days; the detoxified material was added to a fermenter, and the solid content was adjusted to 25%, and the amount of cellulase was 15 FPU / gram of dry solid, Saccharification at 50°C and pH 4.8 for 48 hours; then the supernatant obtained by centrifugation is the straw enzymatic hydrolysis solution. Add 2.5g / L ammonium chloride, potassium dihydrogen phosphate 2.5g / L, magnesium sulfate heptahydrate 0.25g / L, copper sulfate pentahydrate 0.25mg / L, zinc sulfate heptahydrate 1.1mg / L to the enzymolysis solution, Ferrous sulfate heptahydrate 6.5mg / L, manganese chloride 3.6mg / L, and insert cultured Aspergillus niger M288 (purchased from Shanghai Institute of Industrial Microbiology Culture Collection Cent...

Embodiment 2

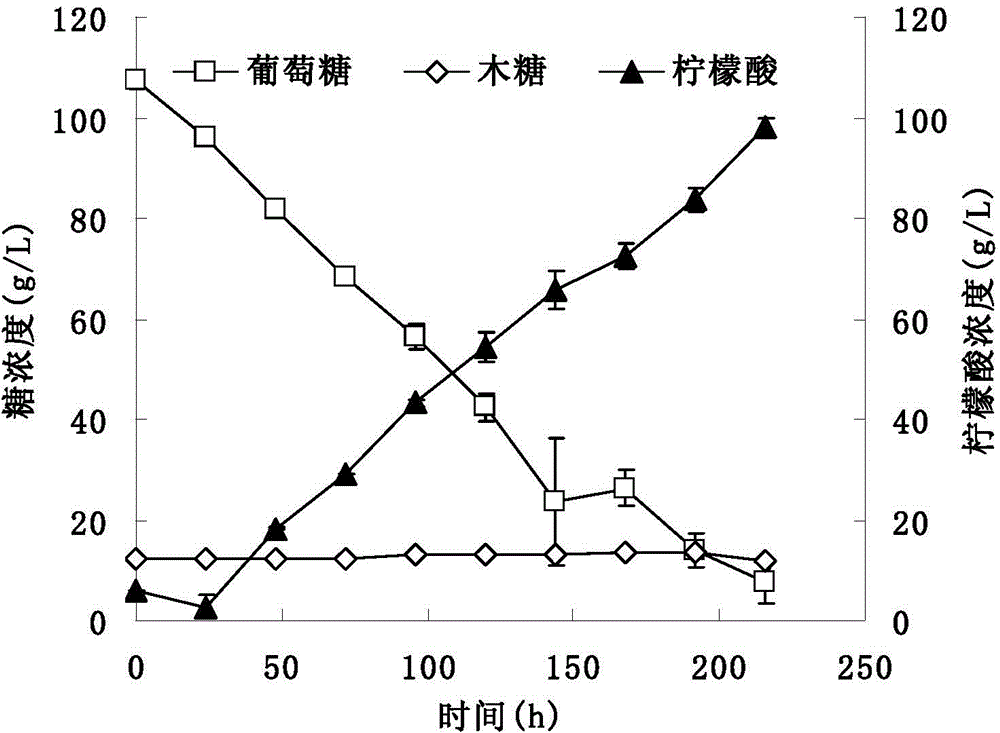

[0034] Mix the dried corn stalks with 5% dilute sulfuric acid solution at a mass ratio of 2:1, and then pretreat them at 190°C and 1.2MPa for 3 minutes; The used bacterial species Amorphotheca resinae ZN1 (its preservation number CGMCC7452) was detoxified in a solid state at 25°C for 10 days; the detoxified material was added to a fermenter, and the solid content was adjusted to 25%, and the amount of cellulase was 15 FPU / gram of dry solid, Saccharification at 50°C and pH 4.8 for 48 hours; then the supernatant obtained by centrifugation is the straw enzymatic hydrolysis solution. Add 1.0g / L ammonium chloride, potassium dihydrogen phosphate 2.5g / L, magnesium sulfate heptahydrate 0.25g / L, copper sulfate pentahydrate 0.25mg / L, zinc sulfate heptahydrate 1.1mg / L to the enzymolysis solution, Ferrous sulfate heptahydrate 6.5mg / L, manganese chloride 3.6mg / L, and insert cultured Aspergillus niger M288 (purchased from Shanghai Institute of Industrial Microbiology Culture Collection Cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com