Preparation method and catalysis applications of efficient and simple zeolite imidazole framework ZIF-8 crystals with different morphologies

A technology of zeolite imidazole skeleton and ZIF-8, which is applied in the direction of catalytic reaction, preparation of organic compounds, preparation of carboxylic acid nitrile, etc., to achieve the effect of high product yield, uniform appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

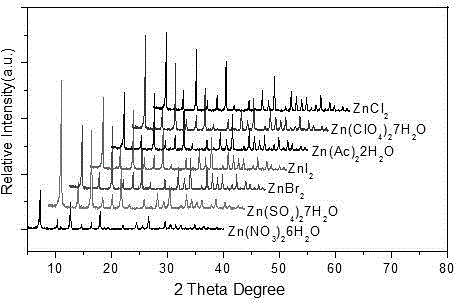

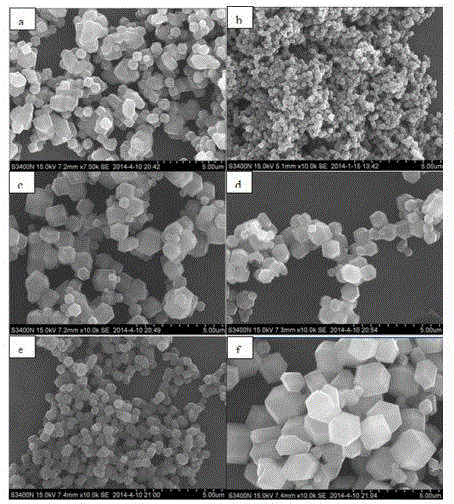

[0040] First, 8 mmol of zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) Dissolve in 1.4mol of methanol, stir until fully dissolved; then, dissolve 64.4mmol of 2-methylimidazole (Mim) in 1.4mol of methanol, stir until fully dissolved; mix the above two solutions and place in a beaker Stir vigorously for 12 hours, seal with plastic wrap, centrifuge (8000r / min, 5min) after obtaining a milky white suspension, wash with methanol 3 times, and centrifugally filter, 60 o C dried for 15 hours to obtain the ZIF-8 crystal of the zeolite imidazole framework. Product is identified as ZIF-8 through X-ray powder diffraction; Powder X-ray diffraction result is as follows figure 1 As shown, the material morphology was obtained by scanning electron microscope results, such as figure 2 As shown in the figure, it can be seen that the material has a regular octahedral structure and is uniform in size.

Embodiment 2

[0042] First, 8 mmol of zinc sulfate heptahydrate (Zn(SO 4 ) 2 ·7H 2 O) Dissolve in 1.4mol of methanol, stir until fully dissolved; then, dissolve 64.4mmol of 2-methylimidazole (Mim) in 1.4mol of methanol, stir until fully dissolved; mix the above two solutions and place in a beaker Stir vigorously for 12 hours, seal with plastic wrap, centrifuge (8000r / min, 5min) after obtaining a milky white suspension, wash with methanol twice, and centrifugally filter, 60 o C and dried for 12 hours to obtain the ZIF-8 crystal of the zeolite imidazole framework. The obtained product is identified by X-ray powder diffraction and scanning electron microscope (similar to ZIF-8 prepared in Example 1), which shows that it is ZIF-8 with regular octahedral structure.

Embodiment 3

[0044] First, 8 mmol of zinc chloride (ZnCl 2 ) was dissolved in 1.4mol of methanol and stirred until fully dissolved; then, 64.4mmol of 2-methylimidazole (Mim) was dissolved in 1.4mol of methanol and stirred until fully dissolved; the above two solutions were mixed and placed in a beaker vigorously Stir for 12 hours, seal with plastic wrap, centrifuge (8000r / min, 5min) after obtaining a milky white suspension, and wash with methanol 5 times, centrifugal filter, 60 o C dried for 24 hours to obtain the zeolite imidazole framework ZIF-8 crystal. The obtained product is identified by X-ray powder diffraction and scanning electron microscope (similar to ZIF-8 prepared in Example 1), which shows that it is ZIF-8 with regular octahedral structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com