Urethane-acrylate copolymer and photoresist composition thereof

A technology of urethane acrylate and acrylate, which is applied in the field of photoresist to achieve the effect of improving heat resistance and hardness, good comprehensive performance and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

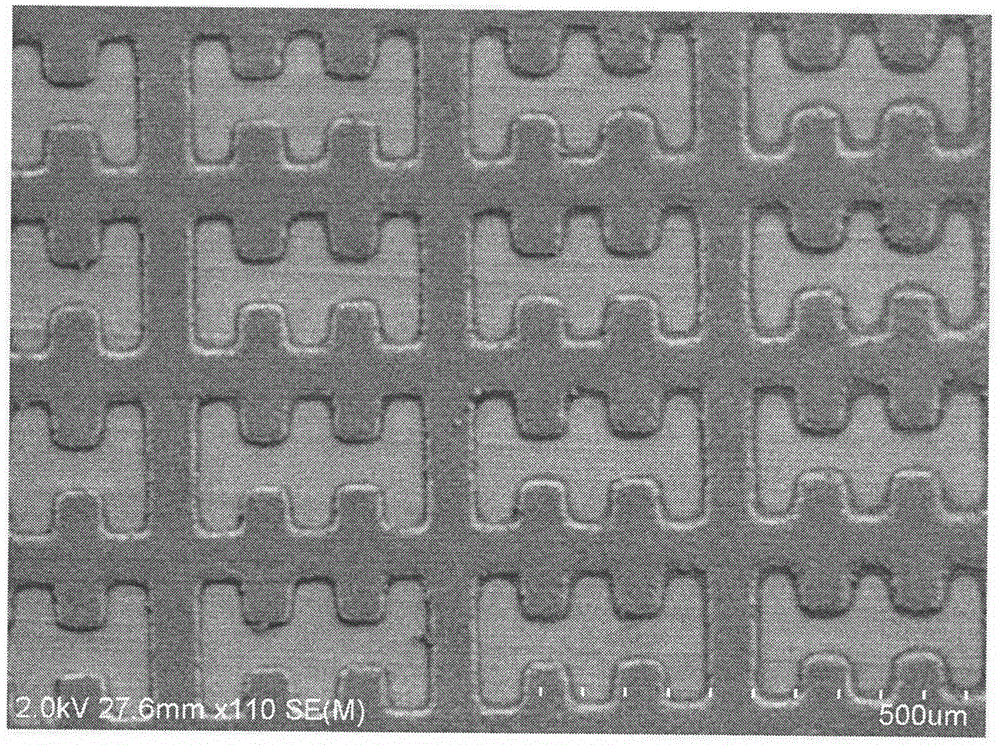

Examples

Embodiment 1

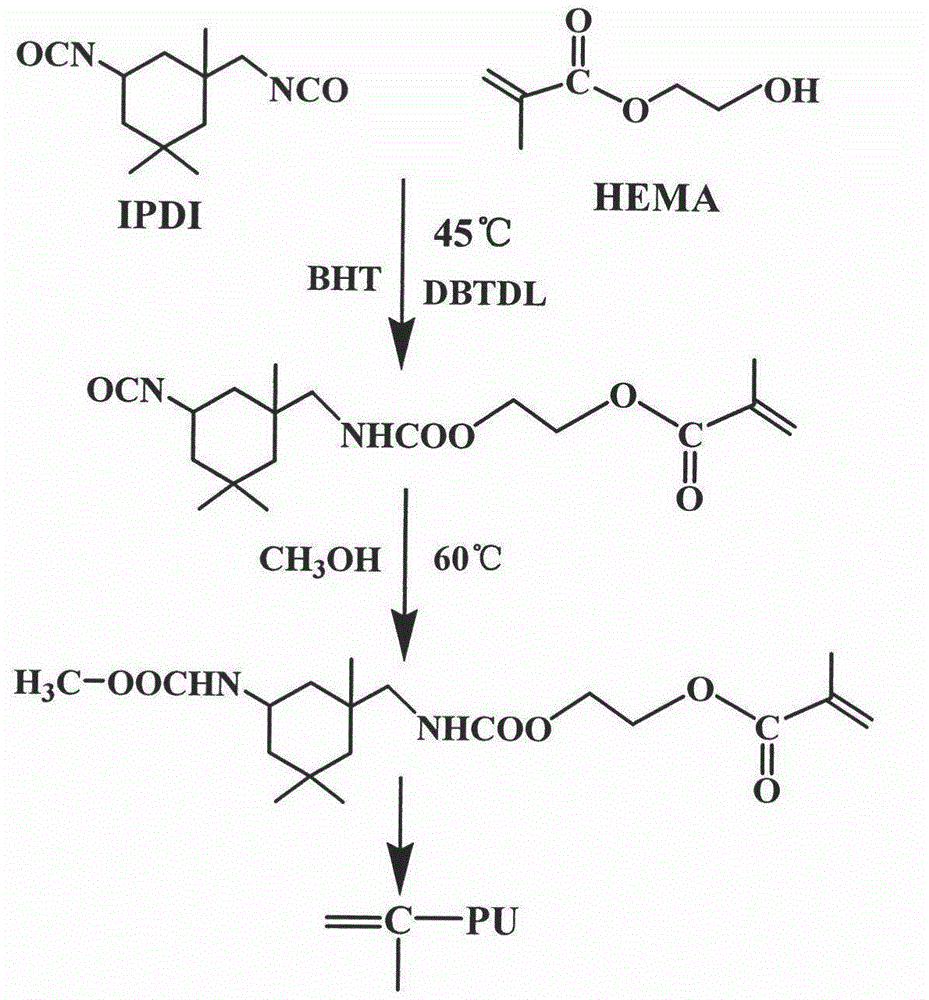

[0022] (1) Preparation of polyurethane acrylate monomer (PUA): add isophorone diisocyanate (IPDI) 133.38g and dilauric acid di Butyl tin (DBTDL) 0.42g, then add 0.31g polymerization inhibitor 2,6-di-tert-butyl-p-cresol, add dropwise 80.41g hydroxyethyl methacrylate at 45°C, keep the temperature for 2h, then raise the temperature to 60 °C, 25 g of anhydrous methanol was added to finally obtain a urethane acrylate monomer. The whole process measures the NCO group content during the reaction by the toluene-di-n-butylamine back titration method, and proceeds to the next step of reaction when it is close to the theoretical NCO value.

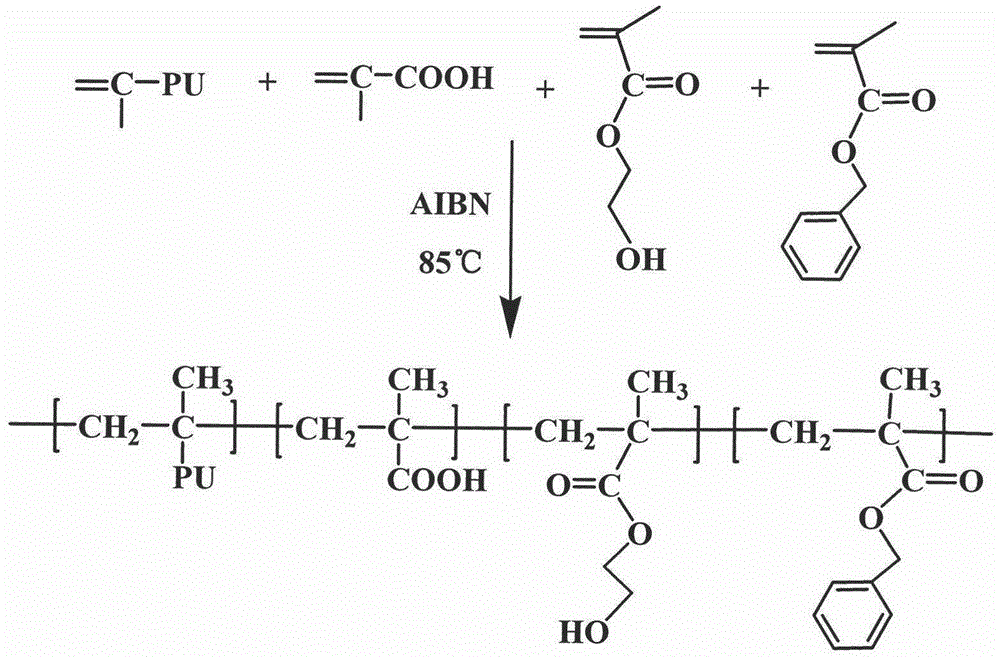

[0023] (2) Preparation of polyurethane acrylate copolymer: Add 40g of propylene glycol methyl ether acetate into a 250ml four-necked round-bottomed flask equipped with a thermometer, a reflux condenser, and a stirrer, raise the temperature to 85°C and allow it to reflux, and then drop A monomer mixture mixed with 2.4 g of initiator azobisisobutyroni...

Embodiment 2

[0026] (1) Preparation of polyurethane acrylate monomer (PUA): add isophorone diisocyanate (IPDI) 133.38g and dilauric acid di Butyl tin (DBTDL) 0.42g, then add 0.31g polymerization inhibitor 2,6-di-tert-butyl-p-cresol, add dropwise 80.41g hydroxyethyl methacrylate at 45°C, keep the temperature for 2h, then raise the temperature to 60 °C, 25 g of anhydrous methanol was added to finally obtain a urethane acrylate monomer. The whole process measures the NCO group content during the reaction by the toluene-di-n-butylamine back titration method, and proceeds to the next step of reaction when it is close to the theoretical NCO value.

[0027] (2) Preparation of polyurethane acrylate copolymer: Add 40g of propylene glycol methyl ether acetate into a 250ml four-necked round-bottomed flask equipped with a thermometer, a reflux condenser, and a stirrer, raise the temperature to 85°C and allow it to reflux, and then drop A monomer mixture with 2.1 g of initiator azobisisobutyronitrile,...

Embodiment 3

[0030] (1) Preparation of polyurethane acrylate monomer (PUA): add isophorone diisocyanate (IPDI) 133.38g and dilauric acid di Butyl tin (DBTDL) 0.42g, then add 0.31g of polymerization inhibitor 2,6-di-tert-butyl-p-cresol, drop 71.82g of hydroxyethyl acrylate at 45°C, keep the temperature for 2h, then raise the temperature to 60°C, 25 g of anhydrous methanol was added to finally obtain a urethane acrylate monomer. The whole process measures the NCO group content during the reaction by the toluene-di-n-butylamine back titration method, and proceeds to the next step of reaction when it is close to the theoretical NCO value.

[0031] (2) Preparation of polyurethane acrylate copolymer: Add 40g of propylene glycol methyl ether acetate into a 250ml four-necked round-bottomed flask equipped with a thermometer, a reflux condenser, and a stirrer, raise the temperature to 85°C and allow it to reflux, and then drop A monomer mixture mixed with 2.4 g of initiator azobisisobutyronitrile, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com