A kind of inorganic-organic covalent hybrid flocculant and preparation method thereof

A flocculant and organic technology, applied in the field of inorganic-organic covalent hybrid flocculants and their preparation, can solve the problems of the flocculant's electrical neutralization ability and poor stability, and achieve good flocculation effect, high molecular weight and fast precipitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

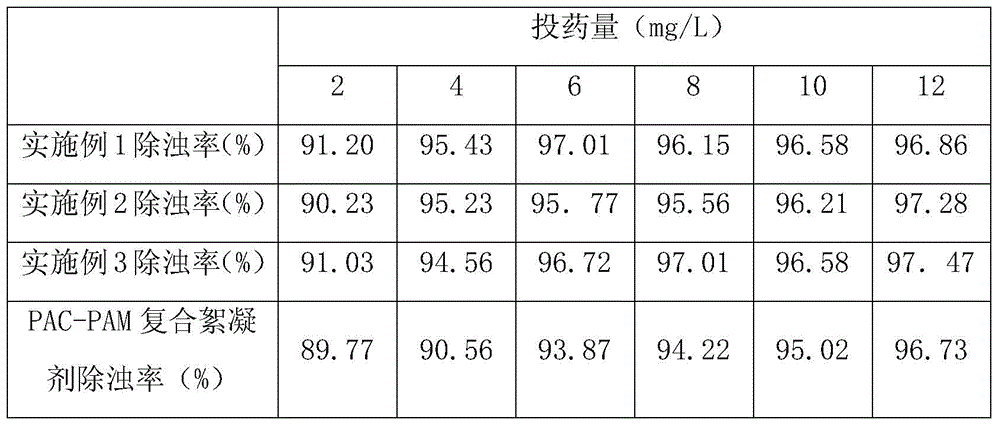

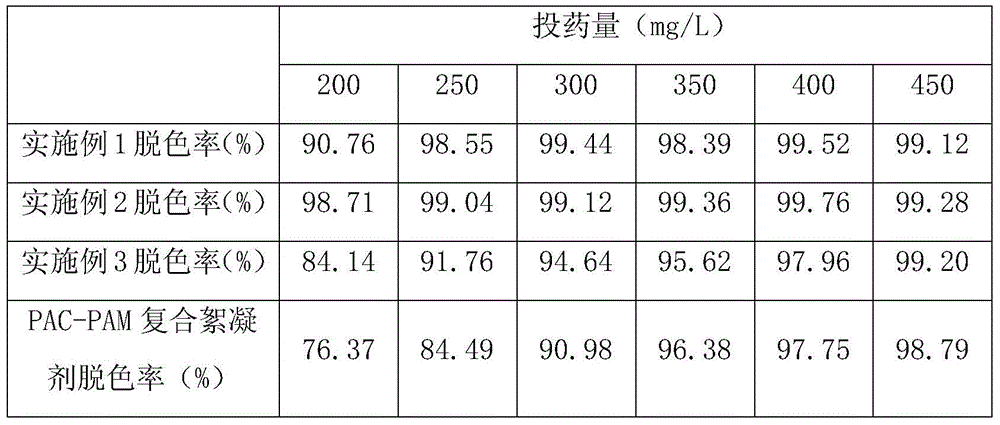

Embodiment 1

[0029] Example 1 Preparation of inorganic-organic covalent hybrid flocculant

[0030] In the first step, mix 36mL of absolute ethanol with 4mL of water, adjust the pH to 4 with 5% hydrochloric acid, add 2mL of KH-570 (that is, γ-methacryloxypropyltrimethoxysilane) to the mixed solution, Hydrolysis for 12h. Take 3.6mL from the above solution and mix it with 100mL20g / L complete polyaluminum chloride solution, place it in a three-necked flask, and then adjust the pH to 10 with sodium hydroxide solution;

[0031] In the second step, add 0.6 g of acrylamide monomer to the above solution, stir evenly, pass high-purity nitrogen into the solution to remove oxygen, and slowly add 3.6 mL of ammonium persulfate solution with a concentration of 1 g / L dropwise under nitrogen protection. Stir evenly and seal;

[0032] The third step is to react the above-mentioned sealing solution at 65°C for 3 hours, and the product is precipitated with ethanol, filtered with filter paper, washed with ac...

Embodiment 2

[0033] Example 2 Preparation of inorganic-organic covalent hybrid flocculant

[0034] In the first step, mix 36 mL of absolute ethanol with 4 mL of water, adjust the pH to 4 with 5% hydrochloric acid, add 2 mL of KH-570 to the mixed solution, and hydrolyze for 12 hours. Take 3.6mL from the above solution and mix it with 100mL20g / L complete polyaluminum chloride solution, place it in a three-necked flask, and then adjust the pH to 10 with sodium hydroxide solution;

[0035] In the second step, add 0.4 g of acrylamide monomer to the above solution, stir evenly, pass high-purity nitrogen into the solution to remove oxygen, and slowly add 2 mL of ammonium persulfate solution with a concentration of 1 g / L dropwise under the protection of nitrogen, and stir Uniform, sealed;

[0036] The third step is to react the above sealing solution at 70°C for 2 hours, and the product is precipitated with ethanol, filtered with filter paper, washed with acetone, dried and ground to obtain an in...

Embodiment 3

[0037] Example 3 Preparation of inorganic-organic covalent hybrid flocculant

[0038] In the first step, mix 36 mL of absolute ethanol with 4 mL of water, adjust the pH to 4 with 5% hydrochloric acid, add 2 mL of KH-570 to the mixed solution, and hydrolyze for 12 hours. Take 3.6mL from the above solution and mix it with 100mL20g / L complete polyaluminum chloride solution, place it in a three-necked flask, and then adjust the pH to 10 with sodium hydroxide solution;

[0039] In the second step, add 0.8 g of acrylamide monomer to the above solution, stir evenly, pass high-purity nitrogen into the solution to remove oxygen, and slowly add 5.6 mL of ammonium persulfate solution with a concentration of 1 g / L dropwise under nitrogen protection. Stir evenly and seal;

[0040] The third step is to react the above sealing solution at 50°C for 4 hours, and the product is precipitated with ethanol, filtered with filter paper, washed with acetone, dried and ground to obtain an inorganic-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com