Specific compound enzyme for husk barley and full-husk barley-type feed and preparation method thereof

A technology of compound enzyme and barley barley is applied in the directions of biochemical equipment and methods, animal feed, animal feed, etc., to achieve the effect of improving economic benefits and reducing feed costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Hull Barley Component Determination

[0035] Table 1 Determination results of husk barley components

[0036] project

[0037] Arginine, %

[0038] It can be seen from the analysis and detection indicators that the crude protein content of husk barley is higher than that of corn, the available phosphorus content is low, and the true amino acid digestibility of poultry is relatively low (about 80.0%), which is more than 5% lower than that of corn. In addition, the AME values for poultry are lower than for corn. The content of anti-nutritional factors β-glucan and arabinoxylan is high.

Embodiment 2

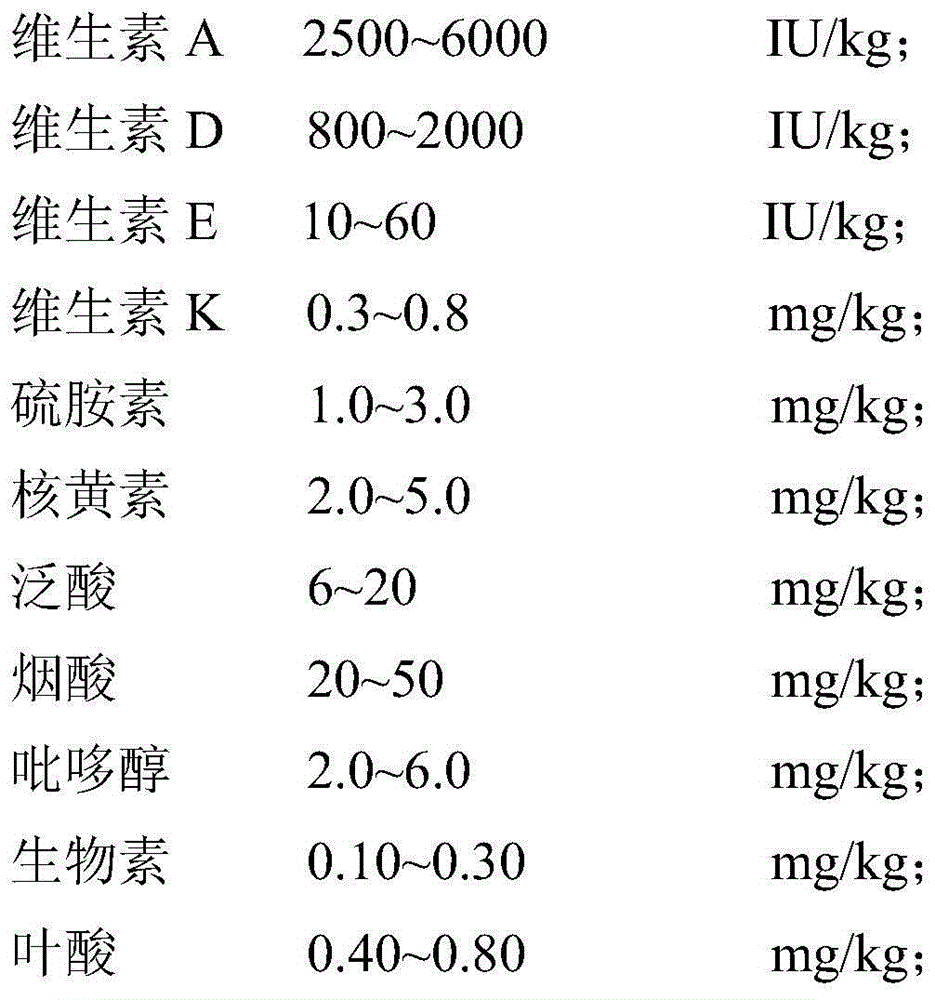

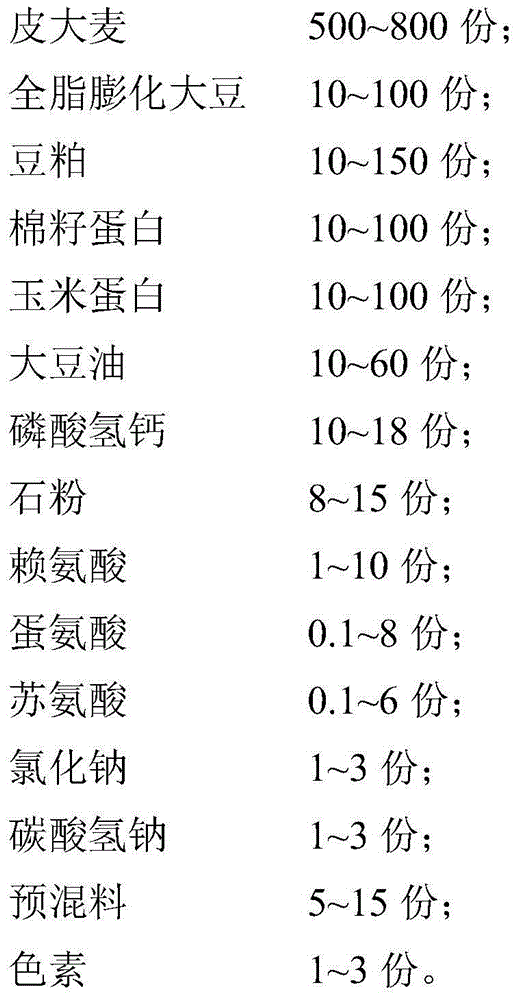

[0040] Produce 1 ton of yellow-feathered broiler feed formula as following table 2:

[0041] Table 2 Whole Hull Barley Type Feed Formula

[0042]

[0043]

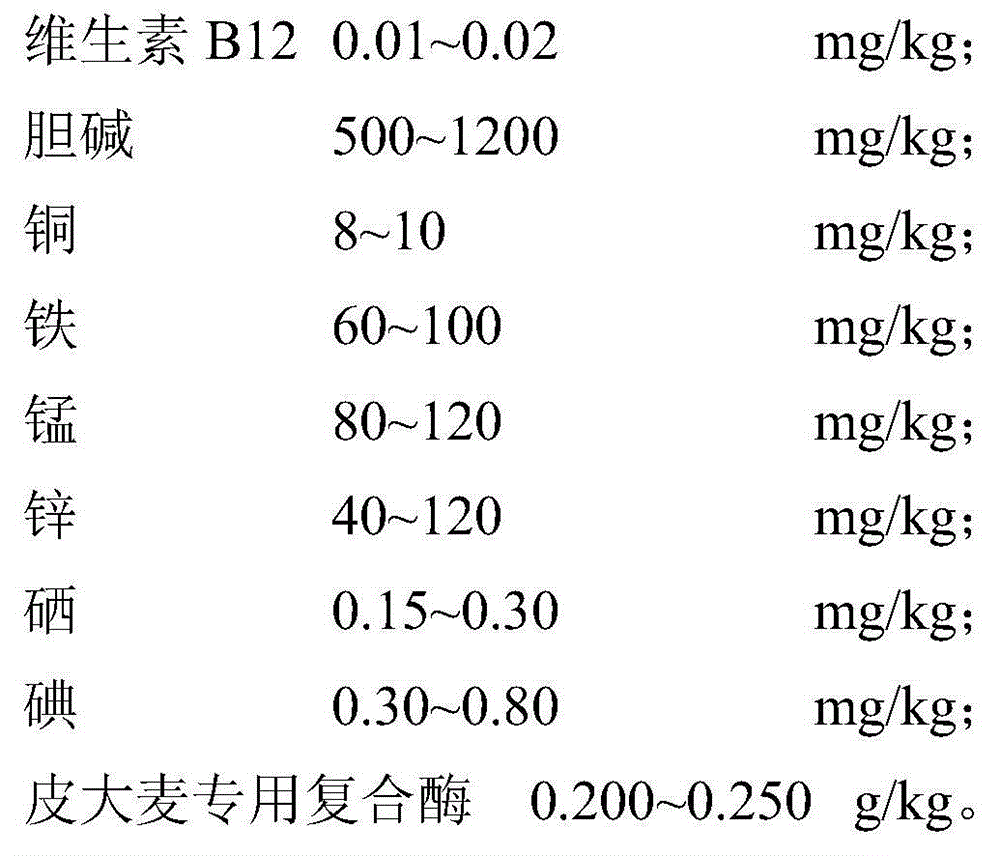

[0044]The premix contains barley-hulled special compound enzyme (250g / ton), including β-glucanase 4000u / g, arabinoxylanase 20000u / g, cellulase 400u / g, phytase 8000u / g , Neutral protease 500u / g, alkaline protease 1000u / g, pectinase 800u / g.

[0045] The preparation method of the whole barley type feed is completed according to the following process steps:

[0046] A. After the raw materials such as barley husk, soybean meal, and corn gluten powder of each weight in Table 2 are removed from impurities, they are pulverized to powder respectively with a pulverizer of 2.5mm sieve.

[0047] B. Then put the pulverized raw materials into the mixer to mix and stir evenly, then mix the lysine, methionine, threonine, sodium bicarbonate, salt, premix, stone powder, calcium hydrogen phosphate After the second premixing, the spe...

Embodiment 3

[0052] The experimental diet formula is as follows in Table 3:

[0053] table 3

[0054]

[0055] Among them, the yellow feather broiler chickens in the control group and the yellow feather broiler chickens in the test group had exactly the same nutritional level of the corresponding diets. They were fed the same feed for 1 to 21 days, and their average weight was 420g. The experiment officially started from the age of 22 days.

[0056] Produce feed according to the feed processing procedure in the above diet formula and example 2, then carry out high-quality chicken feeding test, test is divided into three treatment groups, each handles 6 repetitions, each repeats 75 chickens. The following trials were carried out in summer and no negative effects were observed from the use of hulled barley under conditions of heat stress.

[0057] Control group: feed A1 on 22-43 days, feed A2 on 43-63 days;

[0058] Hulled barley without enzyme group: feed B1 on 22-42 days, and B2 on 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com