A method for micro-arc oxidation of aluminum alloy with green film layer

A micro-arc oxidation, aluminum alloy technology, applied in anodizing and other directions, can solve the problems of poor fouling resistance, scratch resistance and compactness of the micro-arc oxidation film, and the corrosion resistance needs to be improved, and achieves high hardness and low porosity. , good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The present invention selects 6063 aluminum alloy as the base material, its chemical composition is shown in Table 1, and the chemical reagents used in the test are shown in Table 2.

[0050] Table 1 Composition of 6063 aluminum alloy (wt%)

[0051]

[0052] Table 2 Chemical reagents used in the test

[0053]

[0054] In the present invention, the 6063 aluminum plate is cut into 7mm × 7mm × 12mm cuboid fritters on a wire electric discharge machine, and a hole (Ф2.5mm) is drilled on one side thereof with a drilling machine, and taps are tapped with the corresponding taps of the holes. In order to facilitate the tight connection with the tapped aluminum wire during the micro-arc oxidation reaction process, it is ensured that the sample will not fall off during the reaction process. The sample was polished on SiC sandpaper of different thicknesses, starting from 400# coarse sandpaper, and then polished 5 times until fine 1000#. Soak the sample in alcohol to get rid...

Embodiment 2

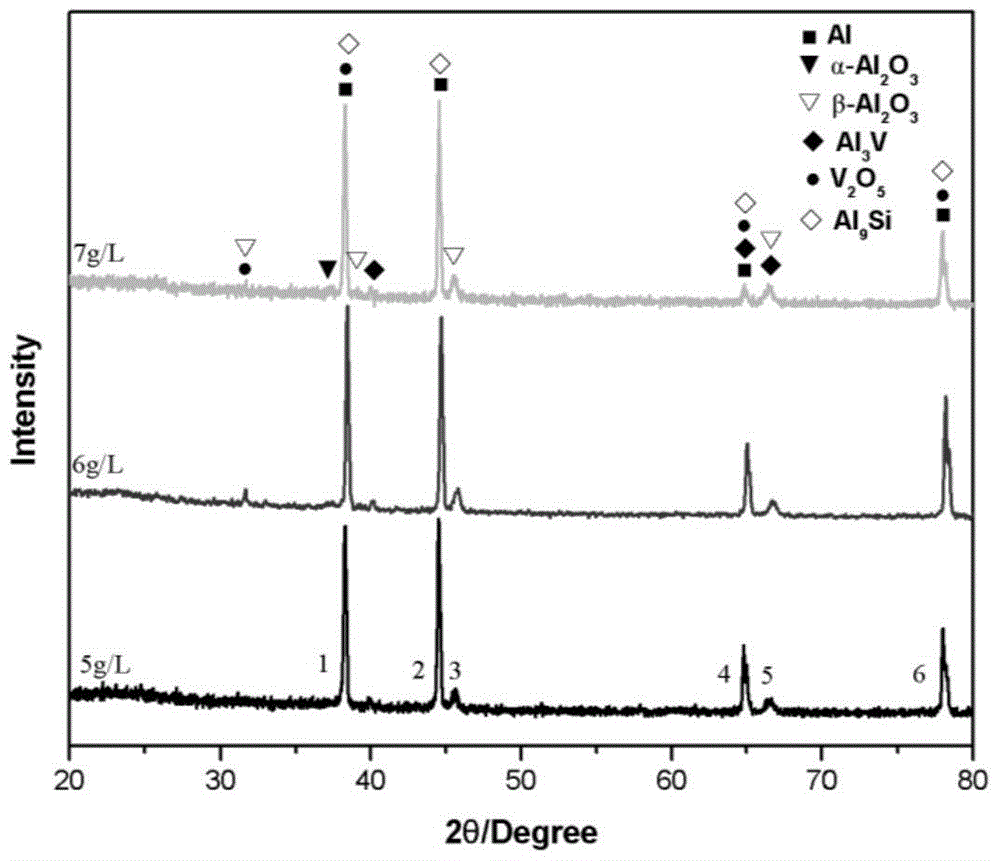

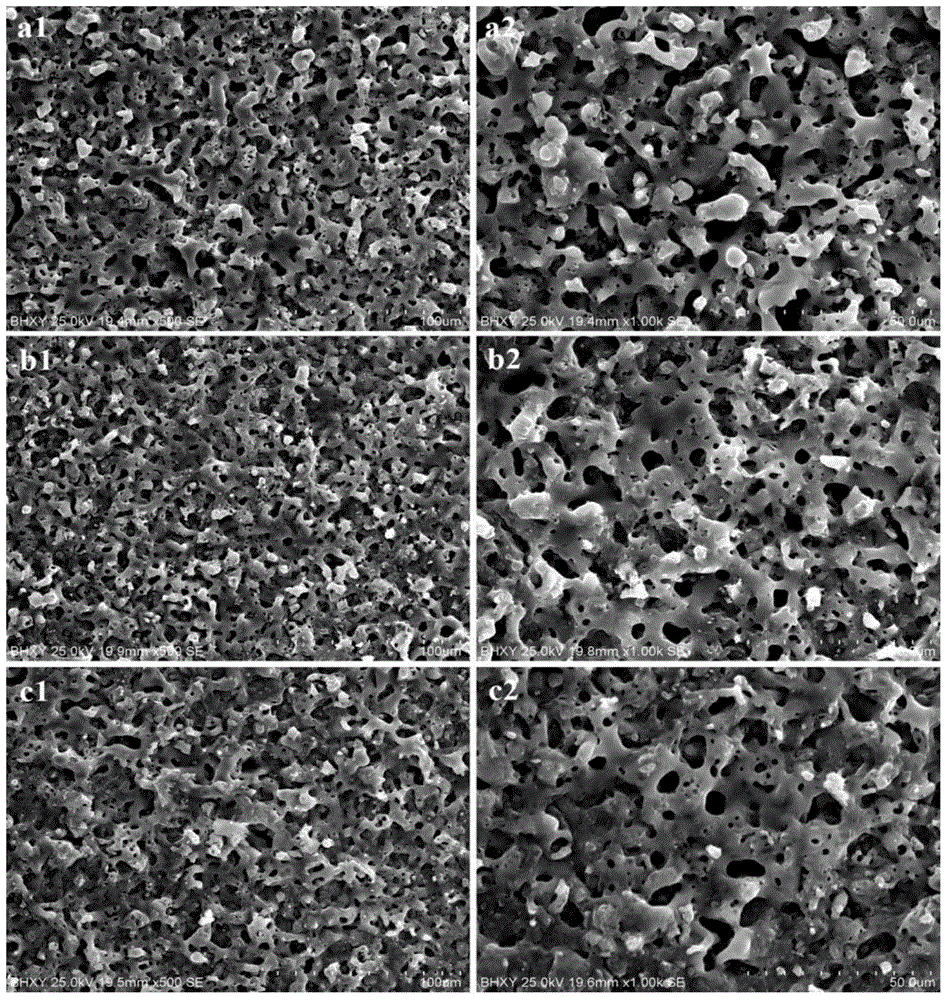

[0057] Changing the concentration of ammonium metavanadate in Example 1 to 5 g / L, and keeping other parameters unchanged, the color of the obtained film layer A1 is very uneven, and many parts appear black.

Embodiment 3

[0059] Changing the concentration of ammonium metavanadate in Example 1 to 7g / L, and keeping other parameters unchanged, the color of the obtained film layer A3 is dark green and the surface is relatively smooth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com