Preparation method of enhanced type composite graphite electrode

A technology of composite graphite and production method, applied in electric heating devices, electrical components, heating by discharge and other directions, can solve the problems of furnace failure, product quality decline, easy occurrence of cracks, etc., to simplify the process, improve the compressive strength, The effect of reducing the cost of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

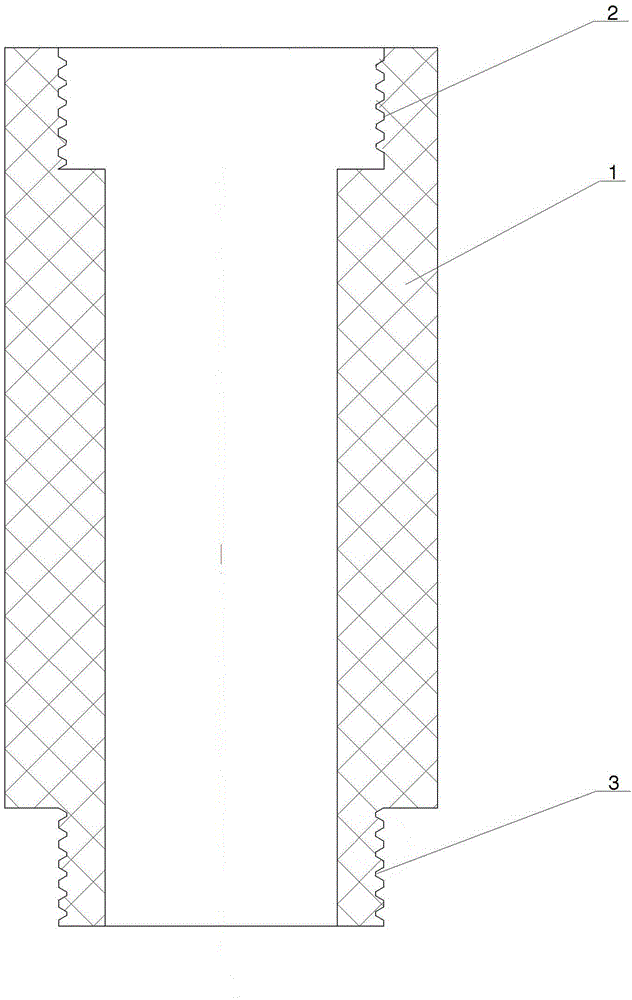

[0043] Example 1 Manufacturing method of enhanced composite graphite electrode shell

[0044] A method for making an enhanced composite graphite electrode shell is as follows:

[0045] Select the following components by weight percentage: 0.075-0.15mm calcined petroleum coke powder 23%,

[0046] 0.5~15mm carbon fiber 5%, 0.5~4mm calcined petroleum coke 25%, 4~10mm calcined petroleum coke 14%, 10~16mm calcined petroleum coke 13%, medium temperature coal tar pitch 20%, the above raw material components are kneaded, After forming, roasting, and graphitization, mechanical processing is carried out to form an electrode shell 1 with internal threads 2 and external threads 3 at both ends. The diameter of the inner cavity of the electrode shell is 600 mm, and the thickness of the graphite electrode shell is 300 mm.

Embodiment 2

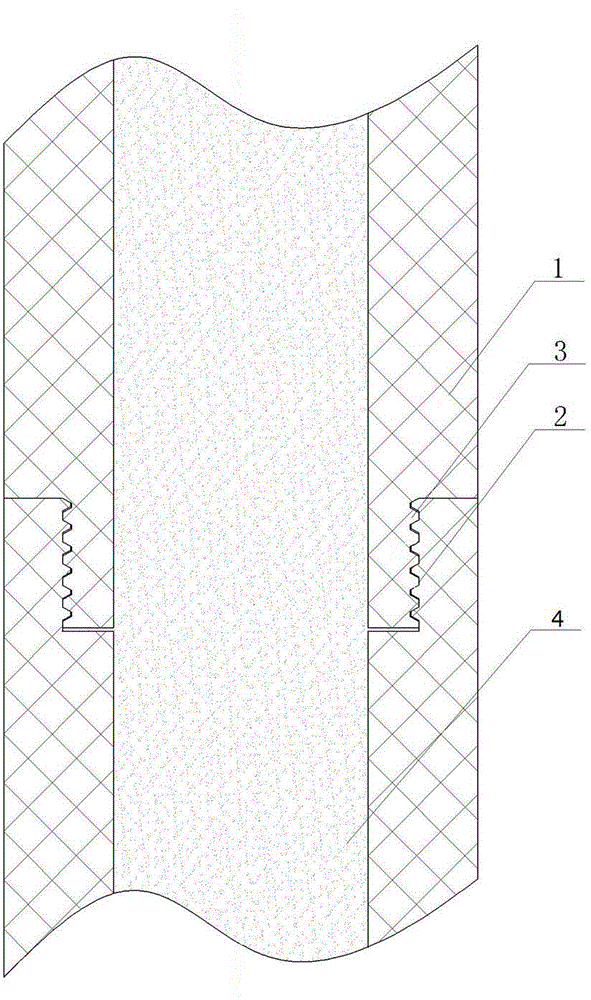

[0047] Example 2 Method of using enhanced composite graphite electrode shell (preparation method of enhanced composite graphite electrode)

[0048] When in use, 10 reinforced composite graphite electrode shells obtained in Example 1 are connected into cylindrical electrode shell connectors through the internal threads 2 and external threads 3 arranged at both ends, and the obtained electrode shell connectors are put into In the copper tile, the copper tile is energized; the electrode paste is added into the cavity, and the electrode paste is gradually melted and sintered into a self-baking electrode 4 to form a composite electrode assembly (that is, an enhanced composite graphite electrode), and the resulting composite electrode assembly is put down together Press and release, and send it to the bottom of the furnace shell for electrification and work.

[0049] Of course, when in use, each submerged arc furnace uses the enhanced composite electrode, and 3-6 electrode column...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com