Silane coupling agent-modified hydrophilic PES/GO (polyether sulfone/graphene oxide) composite film and preparation method for same

A technology of silane coupling agent and composite membrane, which is applied in general water supply saving, chemical instruments and methods, permeation/dialysis water/sewage treatment, etc., can solve the problem that PES membrane is easy to be polluted by hydrophobic substances, and improve hydrophilicity Excellent performance in sex and anti-pollution performance, improvement of permeability, and strong reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 0.3g of graphene oxide GO powder into 30mL of dimethylformamide, ultrasonicate at 200W for 2h; add 7.40g of polyethersulfone PES and 0.5g of pore-forming agent PVP, and stir at 50°C for 20h to obtain a uniform Casting solution; after cooling, defoaming, and scraping, put it into a deionized water coagulation bath at 70°C, remove the solvent, wash it with deionized water, and dry it naturally to obtain a polyethersulfone PES / graphene oxide GO composite membrane.

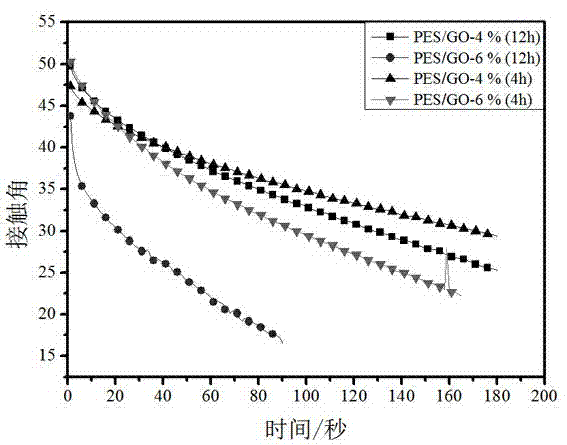

[0026] (2) Cut out a 3cm×3cm PES / GO composite membrane, place it in a 10% ethanol solution of KH570, stir it magnetically for 4 hours, then wash and dry it.

Embodiment 2

[0028] (1) Add 0.3g of graphene oxide GO powder into 30mL of dimethylformamide, ultrasonicate at 200W for 2h; add 7.40g of polyethersulfone PES and 0.5g of pore-forming agent PVP, and stir at 50°C for 20h to obtain a uniform Casting solution; after cooling, defoaming, and scraping, put it into a deionized water coagulation bath at 70°C, remove the solvent, wash it with deionized water, and dry it naturally to obtain a polyethersulfone PES / graphene oxide GO composite membrane.

[0029] (2) Cut out a 3cm×3cm PES / GO composite membrane, place it in a 10% ethanol solution of KH570, stir it magnetically for 6 hours, then wash and dry it.

Embodiment 3

[0031] (1) Add 0.3g of graphene oxide GO powder into 30mL of dimethylformamide, ultrasonicate at 200W for 2h; add 7.40g of polyethersulfone PES and 0.5g of pore-forming agent PVP, and stir at 50°C for 20h to obtain a uniform Casting solution; after cooling, defoaming, and scraping, put it into a deionized water coagulation bath at 70°C, remove the solvent, wash it with deionized water, and dry it naturally to obtain a polyethersulfone PES / graphene oxide GO composite membrane.

[0032] (2) Cut out a 3cm×3cm PES / GO composite membrane, place it in a 10% ethanol solution of KH570, stir it magnetically for 8 hours, then wash and dry it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com