Preparation method for template-free synthesis of phosphoric acid microspheres

An antimony phosphate microsphere, template-free technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as cumbersome preparation methods, achieve simple preparation process, large-scale synthetic product yield, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for template-free synthesis of antimony phosphate microspheres, comprising the steps of:

[0035] S1. Dissolve 1.5mmol antimony potassium tartrate in 60ml ethylene glycol, stir until completely dissolved. Then add 20mmol of phosphoric acid, stir for 30 minutes and mix well.

[0036] S2. The mixed solution obtained in S1 was transferred to a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a dry box, and reacted at 180°C for 8 hours. Then cool naturally to room temperature, rinse the obtained precipitate three times with deionized water and absolute ethanol, centrifuge, and dry in a vacuum oven at 80°C for 12 hours to obtain antimony phosphate flower-shaped hollow microspheres.

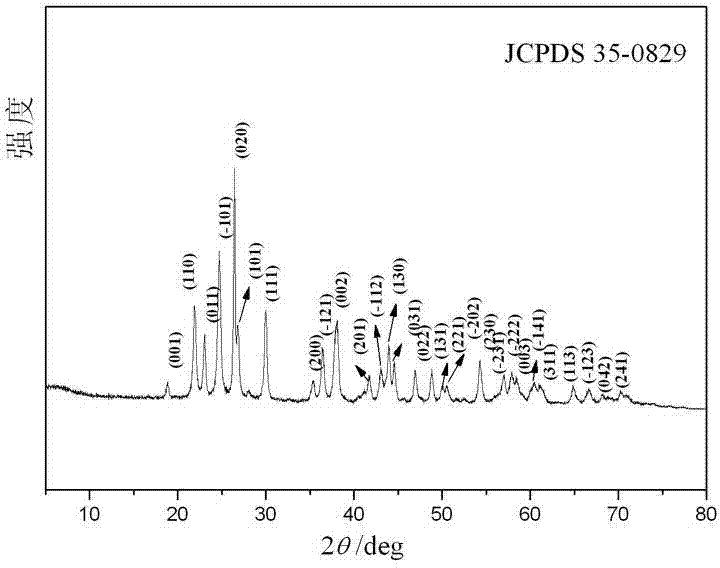

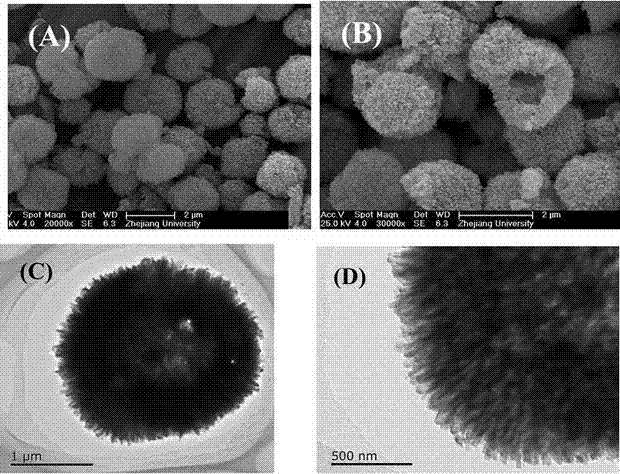

[0037] The X-ray diffraction figure of the antimony phosphate product that makes is shown in figure 1 , the position and intensity of each diffraction peak in the figure are consistent with the standard diffraction card monoclinic antimon...

Embodiment 2

[0040] A preparation method for template-free synthesis of antimony phosphate microspheres, comprising the steps of:

[0041] S1. Dissolve 1mmol antimony potassium tartrate in 60ml ethylene glycol and stir until completely dissolved. Then add 12mmol of phosphoric acid, stir for 30 minutes and mix well.

[0042] S2. The mixed solution obtained in S1 was transferred to a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a dry box, and reacted at 180°C for 8 hours. Then cool naturally to room temperature, rinse the obtained precipitate three times with deionized water and absolute ethanol, centrifuge, and dry in a vacuum oven at 80°C for 12 hours to obtain antimony phosphate flower-shaped hollow microspheres.

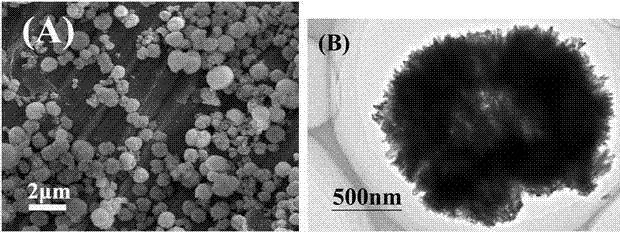

[0043] The SEM and TEM images of the antimony phosphate product are shown in image 3 (A) and 3(B), showing that the antimony phosphate product is a flower-like microsphere with a hollow structure and a relatively uniform shape and size, w...

Embodiment 3

[0045] A preparation method for template-free synthesis of antimony phosphate microspheres, comprising the steps of:

[0046] S1. Dissolve 1.5mmol antimony potassium tartrate in 60ml ethylene glycol, stir until completely dissolved. Then add 20mmol of phosphoric acid, stir for 30 minutes and mix well.

[0047] S2. The mixed solution obtained in S1 was transferred to a 100ml stainless steel reaction kettle lined with polytetrafluoroethylene, placed in a dry oven, and reacted at 150°C for 8 hours. Then cool naturally to room temperature, rinse the obtained precipitate three times with deionized water and absolute ethanol, centrifuge, and dry in a vacuum oven at 80°C for 12 hours to obtain antimony phosphate flower-shaped hollow microspheres.

[0048] The scanning electron micrograph of the antimony phosphate product that makes is shown in Figure 4 , showing that the antimony phosphate product is a flower-like microsphere with a hollow structure and a relatively uniform shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com